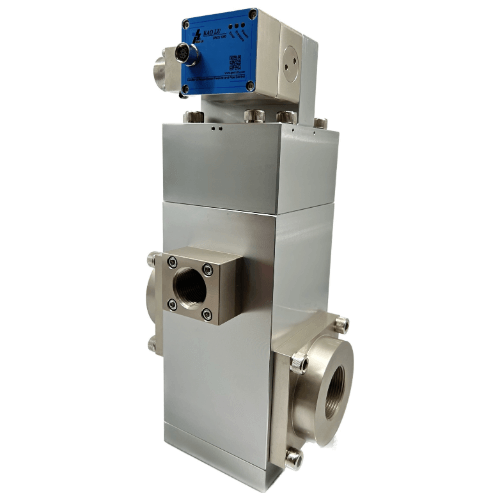

產品型號: QKL-B1T/QKL-B3-1/QKL-B3-1A

此為一個閉迴路設計,由兩個電磁閥、壓力傳感器以及電子迴路控制所組成。

根據接收到的類比訊號輸入,由一端電磁閥用來控制進氣量,與另一端電磁閥來控制排氣量,透過壓力傳感器測量得到並回饋於電子迴路控制,以達到精確的壓力比例控制,該比例閥適合針對隨時需要精準調控壓力變化,與監控壓力值的產業。

比例閥輸入信號提供了0-10VDC(電壓) 與 4-20mA(電流) 及 RS485 ModBus 通訊選擇。監控輸出則有 1-5V、0-10V及4-20mA 的選擇。B1T、B3-1、B3-1A 系列為內部壓力傳感器 B2T、B3-2 系列為搭配外部壓力傳感器 (※適合用於遠端造成壓差的環境條件下)壓力控制器,除了會自行調控達到恆壓以外,還能回饋參數到機台上做監控,排除壓力值不準或壓差造成的震盪問題。

本產品皆符合CE認證、SGS、RoHS、ISO13485 等認證。

產品特色 Features

◆ 體積小 Compact

◆ 精度高 High Precision

◆ 靈敏度高 High Sensitivity

◆ 廣泛的壓力範圍 Wide Pressure Range

產業應用 Industrial application

◆ 雷射切割 Laser Cutter

◆ 洩漏測試 Leak Tester

◆ 張力控制 Tension Control

◆ 吹瓶機產品成型 PET bottle molding machine

◆ 多段壓力控制 Multi-Stage Pressure Control

| 系列 | B1T | B3-1 | B3-A(經濟型) | |||

|---|---|---|---|---|---|---|

| 輸入訊號 | 0-10V / 4-20mA/ RS485 | 0-10V / 4-20mA | ||||

| 輸出壓力 | 0-2bar (29 psi) |

0-4bar (58 psi) |

0-8bar (116psi) |

0-4bar (58 psi) |

0-8bar (116psi) |

0-8bar (116 psi) |

| 建議最大入氣壓力 | 3bar (43 psi) |

5bar (73 psi) |

9bar (131 psi) |

5bar (73 psi) |

9bar (131 psi) |

9bar (131 psi) |

| 最大工作壓力 | 9 bar(131 psi) | |||||

| 監控信號 | 1-5V / 0-10V / 4-20mA | 0-10V / 4-20mA | ||||

| 工作電源 | DC24V (≦4W) | |||||

| 響應時間 | 0.8S | |||||

| 介質 | 潔淨壓縮空氣或搭配5μm過濾器 | |||||

| 重複精度 | ±0.1% F.S. | ±0.25% F.S. | ±0.5% F.S. | |||

| 遲滯 | ±0.2% F.S. | ±0.25% F.S. | ±0.5% F.S. | |||

| 線性度 | ±0.3% F.S. | ±0.3% F.S. | ±0.5% F.S. | |||

| 綜合精度 | ±0.3% F.S. | ±0.5% F.S. | ||||

| 流量 | 4L/min @2bar |

7L/min @4bar |

13L/min @8bar |

525L/min @4bar |

1050L/min @8bar |

1050L/min@8bar |

| 使用溫度範圍 | 0-70⁰C ( 32-158 ⁰F) | |||||

| 牙口 | PT 1/8" | G 1/4" | ||||

| 底座材質 | 鋁合金 | |||||

| 電氣連接 | M12電氣端子(2m) | |||||

| 防護等級 | IP 65 | |||||

| 閥體操作次數 | 10億次以上 | |||||

| 重量 | 420 g | 550 g | 430 g | |||

| Series | Type | Input Signal | Monitor Output | Mounting Bracket | Pressure and Flow | Display Unit | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| QKL- | B1T | - | E | - | C | - | M | - | P8 | - | U |

| B1T: Low flow with internal feedback | **E: 0-10V | C:0-10V | M:M type | For B1T, B2T P2:0 - 2 bar, 8LPM P4:0 - 4 bar, 10LPM P8:0 - 8 bar, 20LPM |

S:psi | ||||||

| B2T: Low flow with external feedback | A: 4-20mA | A:4-20mA | L:L type | U:bar | |||||||

| B3-1: High flow with internal feedback | R: RS485 Modbus | D:1-5V | For B3-1, B3-2 P4:0 - 4 bar, 320 LPM P8: 0 - 8 bar, 640 LPM |

||||||||

| B3-2: High flow with external feedback | |||||||||||

| *B3-A: High flow with internal feedback | For B3A P8:0 - 8 bar, 640 LPM |

*B3-A is an economic type, only with 8 bar. B3-A does not have RS485 modbus interface and does not have 1-5V monitor output.

** For Command Signal type 0-10V, the minimum driving current is 50mA.

★Please consult us for customized pressure range.

The wiring diagram shows from top view.

| No. | Color | Function |

|---|---|---|

| 1 | Blue | 24V DC Power (-) Command (-) Output monitor (-) 2nd loop transducer 0 -10 V (-) |

| 2 | Brown | 24V DC Power (+) 2nd loop transducer 4 - 20 mA (+) |

| 3 | Black | Monitor output (+) |

| 4 | White | 0-5 V Command (+) 0-10 V Command (+) 4-20 mA Command (+) |

| 5 | Gray | RS485(D-) |

| 6 | Green | 2nd loop transducer 0 -10 V (+) 2nd loop transducer 4 - 20 mA (-) |

| 7 | - | - |

| 8 | Red | RS485(D+) |

** Warning: Do not rotate the connection socket when connected, to avoid damage to the internal sensor.

Product Precautions

Installation

The valve can be mounted in any position. For very low pressure control, works best when mounted upright.

And Ensure a minimum closed end volume of 40c.c. to allow proper functioning.

※Preparation Before Piping

Before piping is connected, it should be thoroughly blown out with air (flushing) or washed to remove chips, cutting oil and other debris from inside the pipe.

Wrapping of Sealant Tape

When screwing together pipes and fittings, etc., be certain that chips from the pipe threads and sealing material do not get inside the piping. When sealant tape is used, leave 1.5 to 2 thread ridges exposed at the end of the threads.

Operating Environment

- Do not operate in locations having an atmosphere of corrosive gases, chemicals, sea water, or where there will be contact with the same.

- In locations where the body is exposed to water, steam, dust, etc., there is a possibility that moisture or dust could enter the body through the EXH port, solenoid valve EXH port and/or built-in regulator EXH port, thereby causing problems.

- In locations which receive direct sunlight, provide a protective cover etc.

- In locations near heat sources, block off any radiated heat.

- Employ suitable protective measures in locations where there is contact with water droplets, oil or welding spatter, etc.

Air Supply

- Compressed air, nitrogen, oxygen or argon can be used as a fluid.

- Do not use compressed air which includes chemicals, synthetic oils containing organic solvents, salt, or corrosive gases, etc., as this can cause damage or malfunction.

- If oxygen is used as the fluid, it can lead to serious and unforeseen risks. However, it is possible to manage and control the risk of hazards and economic loss. In order to use the product safely, it should only be handled by personnel with appropriate knowledge, with support from a suitably qualified specialist.

- Oxygen gas increases the susceptibility of substances to burning; Oxygen gas can be ignited by frictional heat and static electricity. If oxygen is ignited, the metal and seal materials burn. Therefore, flush the piping thoroughly and mount a suitable filter to prevent foreign matter such as metal powder and dust from entering the product.

- Take safety measures by installing safety devices (e.g. a circuit that stops the supply of oxygen gas) to prevent fire and explosion in the event of failure, taking flameproof safety standards into consideration.

- Since there are some exhaust ports on the product, connect the piping in order to exhaust oxygen. Do not block the exhaust port.

Warranty

KaoLu Ent. Co. Ltd. products are warranted to the original purchaser only against defects in material or workmanship for 6 months from the date of manufacture. The extent of KaoLu’s liability under this warranty is limited to repair or replacement of the defective unit at KaoLu’s option. KaoLu shall have no liability under this warranty where improper installation or filtration occurred.