分類: 最大容量 1.5 L

國家: 台灣

電話: 886-4-23345536/ 86-595-88169879

傳真: 886-4-23345539/ 86-595-88165687

聯絡人: 黃小姐

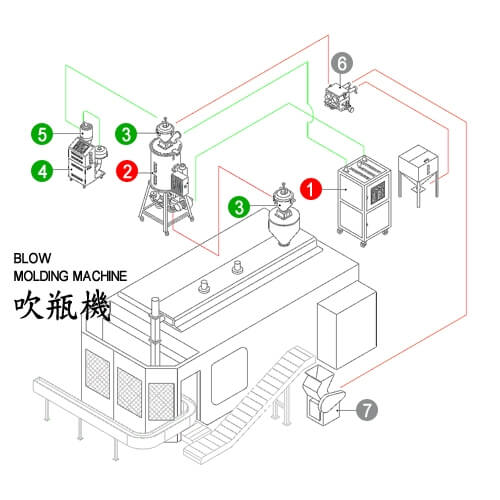

- 採用觸控式彩色人機介面控制系統,操作簡易。

- 獨特的機台組合設計,方便吹瓶線與輸送機構的連線結合。

- 瓶胚自動排列成序後單道入胚,伺服馬達驅動分胚載塊作動及定位,減少卡胚停機。

- 公轉採用螺桿伺服驅動,動作快速穩定外,減少潤滑油使用,既衛生又環保。

- 瓶胚以矩陣模式進加熱單元,採用單燈管雙邊加熱,確保瓶胚受熱均勻,加熱能耗節省約50%。

- 具有溫度反饋功能,自動調節紅外線燈管的功率,有效地減少瓶胚結晶現象發生。

- 獨特的保溫罩設計,提昇紅外線燈管和冷卻水道維修保養的便利性。

- 鎖模機構採用伺服加凸輪結構並配合高壓進行鎖模,作動精確穩定、低噪音、無污染。

- 採用封閉回收功能,回收效率高達50%,不需配置低壓空壓設備,減少設備投資及電力消耗可達15%。

- 出瓶處加裝出瓶銜接機構,與風送道連結,將成型瓶直接傳送至灌裝系統。

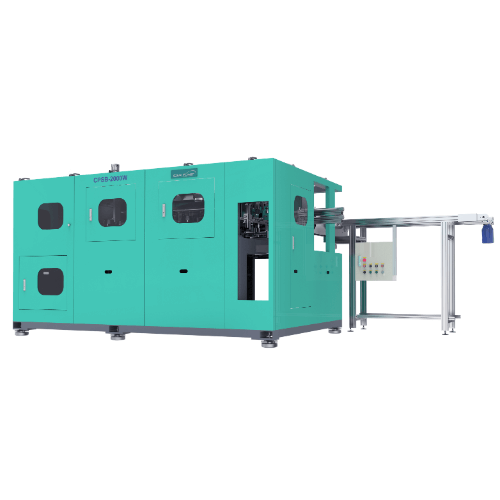

| Model | EX02MC-SH | Unit |

| 穴數 | 2 | cavity |

| 理論產量 | 2000 | BPH |

| 胚頭數 | 62 | pcs |

| 加熱間距 | 62 | mm |

| 瓶子間距 | 114.3 | mm |

| 瓶子容量 | 1.5Ltr. | Max. |

| 牙口尺寸 | 38 | Max. (mm) |

| 瓶胚高度 | 150 | Max. (mm) |

| 瓶身直徑 | 105 | Max. (mm) |

| 瓶身高度 | 320 | Max. (mm) |

| 加熱箱數 | 1*2 | box*channel |

| 加熱功率 | 38 | kW |

| 配置功率 | 48 | kW |

| 機台尺寸 | 230*220*350 | cm |

| 機台重量 | 2500 | kg |

| origin | Taiwan | |

| China | ◎ |