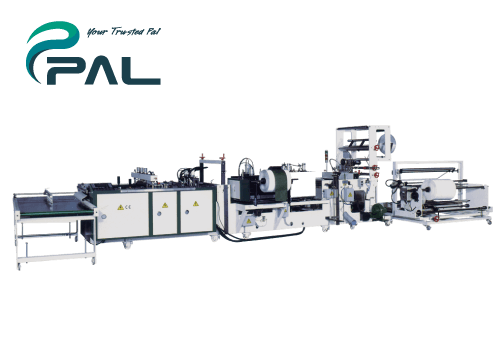

Side Seal System Features

Synchornized Feeding and Cutting Speed

Inverter controlled feeding matching main machine speed for easy operation without manual adjustment.

Cut / Seal Synchonized

Sealing and cutting bag simultaneously, taken out by conveyor

Auxiliary Air Blown Outfeed

Assists material flow during outfeeding

"SICK" Photocell Register

Reliable and accurate print registration and positioning

Malfunction Alarm / Stop

Abnormal temperature / No material feed / Photocell track miss

LCD Touch Panel

Easily operable Human-computer interface for changing & monitoring production parameters.

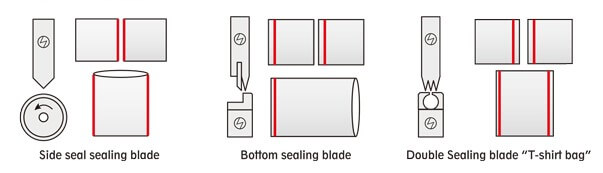

Sealing Blade Type

- Side seal sealing blade

- Bottom sealing blade

- Double Sealing blade "T-shirt bag"

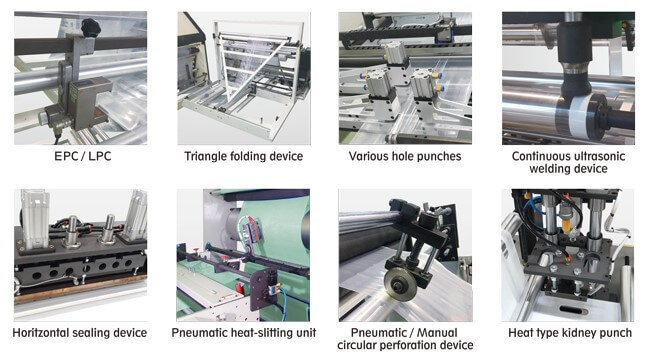

Optional Device

- EPC/LPC

- Triangle folding device

- Various hole punches

- Continuous ultrasonic welding device

- Horitzontal sealing device

- Pneumatic heat-slitting unit

- Pheumatic / Manual circular perforation device

- Heat type kidney punch

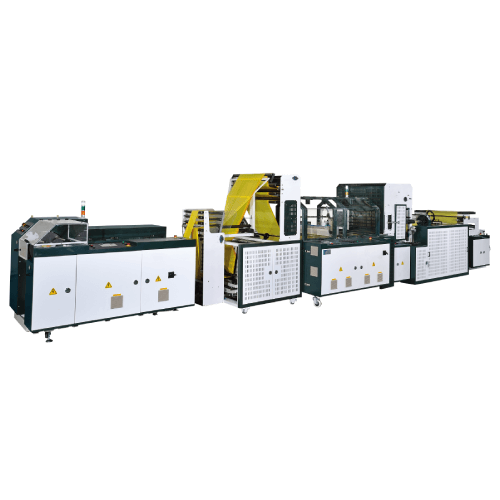

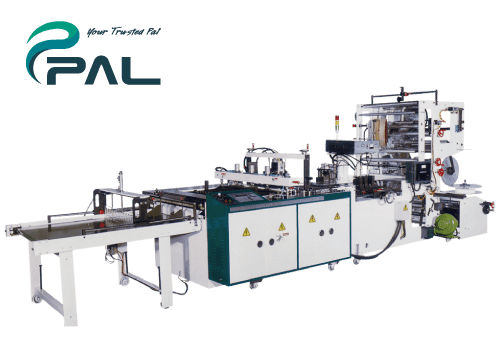

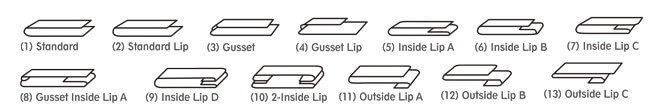

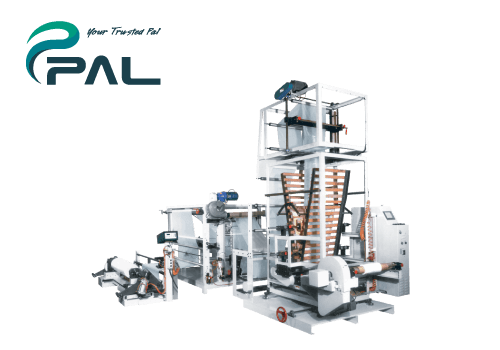

Automatic Side Seal Bag Making Machine

SWC-V

- Servo motor - Accurate & high speed production @180 pcs/min

- Fold & Gusset - 13 types of folding / gusseting formation available

- Versatile production demands - Based upon this standard machine, many optionai devices can be installed for production of different bagsbased on customer / market demands.

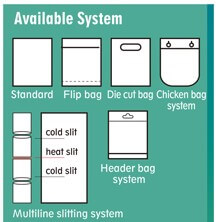

13 Bag Folding Types For Side Seal

Automatic Side Seal Bag Making Machine +Wicketer System

SWKFA-V

- Servo motor - Accurate & high speed production @180 pcs/min

- Wicketer collection - Pin-block collect finished bags into piles for auto-packaging and filling systems

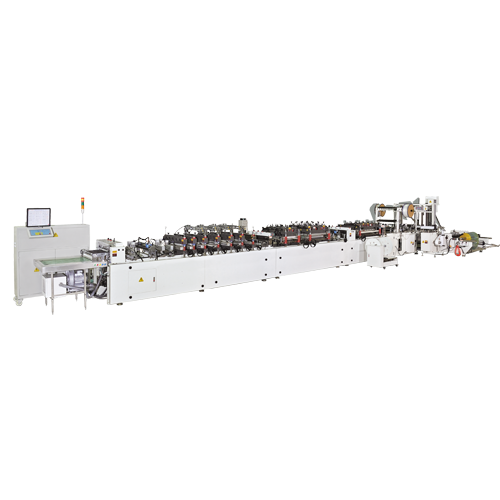

Multi-function Shopping Bag Making Machine

SWPFA-V

- Servo motor - Accurate & high-speed production @120 pcs/min

- Softloop shopping bag - Fully automatic soft-loop film feeding & cutting & positioning & sealing units

- Patch handle bag - Fully automatic patch film feeding & cutting & positioning & sealing units

- Polydraw bag - Drawtape film bobbin feeding & sealing foldmouth by hot-air sealing

- Auxiliary sealing - Reinforced sealing for gusset and foldmouth

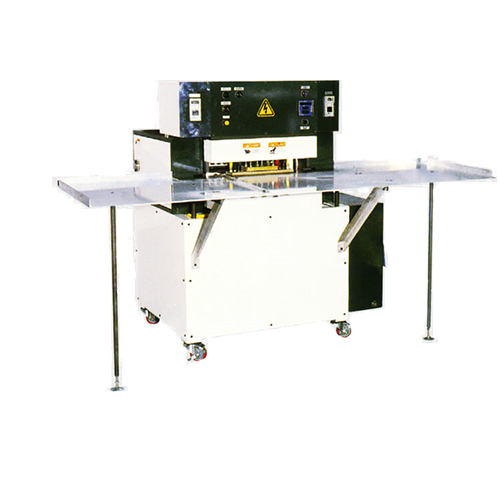

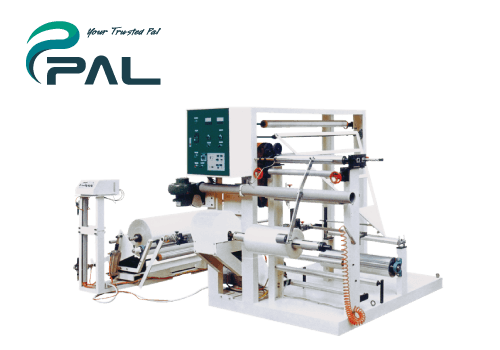

Automatic Sandwich Folding Machine

SF1300/1600

- Preparation for sheet film into folded film rolls

- Design for folding & rewinding OPP / CPP / PE sheet film

- Include Pneumatic film roll loading device & powder brake

Single Sheet Side Edge Heat-slit & Gusset Rewinding Machine

TR1300GT / TR1600GT

- Side slit & seal sheet film after folding and edge trim

- Gusset on 2 sides and rewinding

- Rotation in any degree, avoid overlap seal line & gusset line

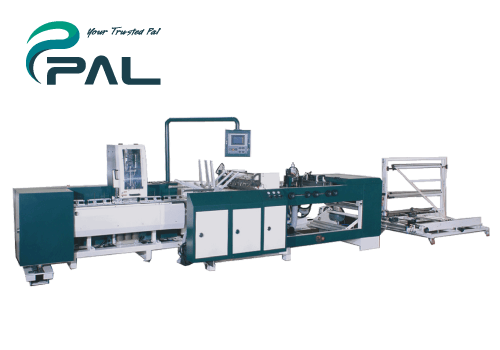

Diaper Bag

- Servo motor - Accurate & high speed production @30~90 pcs/min

- Auto-filling hanging holes - 2 or 3 circular punches & notch punch for auto-filling application

- Breathing holes - Small hole for de-gassing during highspeed auto-filling process

- Handle film insertion - Additional unwinding and positioning for handle film tape

Courier Bag

- Servo motor - Accurate & high speed production @40~120 pcs/min

- Courier pocket film unwinding - Unwinding 2 pocket film rolls with precise positioning

- Courier pocket sealing - Up-down type sealing pocket film

- Optional intermitted Glue applicator - Pneumatically lifting glue applicator on sealing position to avoid glue sticking on cutting blade

- Optional wide sealing - Wide sealing for heavy duty packaging

Beverage Bag

Servo motor - Accurate & high speed production @120 pcs/min

Twinline production - Central -slitting tubic film for 2 lines, Twin die punch units

Bottom separator seal - Up-down auxiliary sealing for the sealed separating line on the center of bag bottom.

Optional calendar system - Pin-block & Hot cut round punch holding bags in piles. Circular continuous perforation for tear-off

Deli Bag / Saddle Bag

- Servo motor - Accurate & high speed production @60~150 pcs/min

- Saddle bag production - Simultaneously feed in twin lines and blocking finished bags, hot-cut round punch and optional central split to make calendar deli bag piles

- Perforation - For continuously perforating tear-line for easy tear-off from header.

- Gripper + pneumatic punch - Gripper take out the blocked bag and pneu-matically splitting & punching the header.

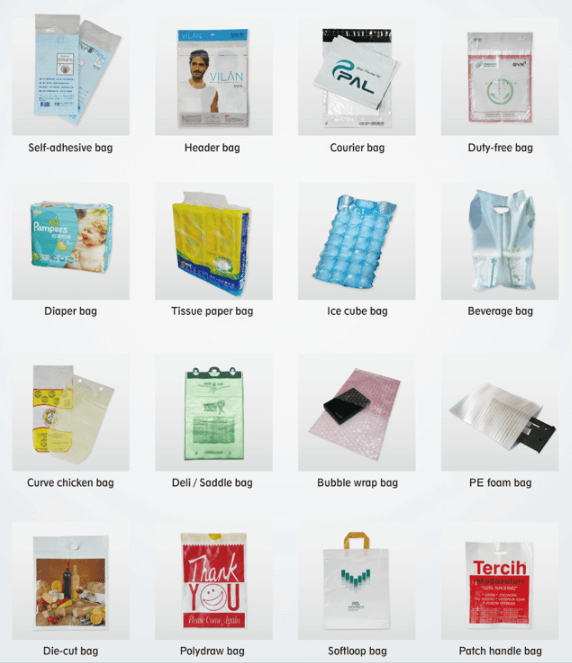

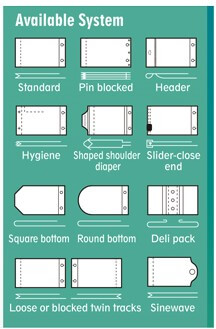

Side Seal Bag Solution

Sideseal bag provides great variaty and go accross multiple packaging area including shopping bags, auto-filling, garment packaging, products packaging, food packaging, electronic packaging, courier services, etc.

| Model | Bag width (inch) | Cutting length (inch) | Cutting speed (strokes/min) | Film thickness (mm) | Tolerance | Power | Machine dimension L x W x H (cm) |

| Sideseal Bag Making Machine | |||||||

| 28SWC-V | 3-30 | 3-26 | 30-180 | 0.012-0.2 | ±1 | 4 | 380 x 140 x 190 |

| 32SWC-V | 3-30 | 3-30 | 30-180 | 0.012-0.2 | ±1 | 4.2 | 380 x 150 x 190 |

| 42SWC-V | 3-40 | 3-40 | 30-180 | 0.012-0.2 | ±1.5 | 4.5 | 380 x 170 x 190 |

| 50SWC-V | 3-40 | 3-48 | 30-170 | 0.012-0.2 | ±1.5 | 5.0 | 380 x 210 x 190 |

| 65SWC-V | 3-40 | 3-63 | 30-170 | 0.012-0.2 | ±1.5 | 6.0 | 380 x 250 x 190 |

| Sideseal Bag Making Machine + Wicketer System | |||||||

| 32SWKFA-V | 6-15 | 10-26 | 60-180 | 0.012-0.15 | ±1 | 5.0 | 780 x 155 x 200 |

| 42SWKFA-V | 6-15 | 10-36 | 60-180 | 0.012-0.15 | ±1.5 | 6.0 | 780 x 180 x 200 |

| Sideseal Softloop Shopping Bag Making Machine | |||||||

| 32SLFA-V | 3-30 | 3-26 | 30-110 | 0.012-0.15 | ±1 | 5.0 | 770 x 180 x 180 |

| 42SLFA-V | 3-40 | 3-36 | 30-110 | 0.012-0.15 | ±1.5 | 5.5 | 770 x 210 x 160 |

| Sideseal Patch Handle Shopping Bag Making Machine | |||||||

| 28PHFA-V | 3-30 | 3-26 | 30-110 | 0.012-0.15 | ±1 | 5.0 | 750 x 170 x 190 |

| 32PHFA-V | 3-30 | 3-30 | 30-110 | 0.012-0.15 | ±1 | 5.5 | 750 x 180 x 190 |

| 42PHFA-V | 3-40 | 3-40 | 30-110 | 0.012-0.15 | ±1.5 | 5.7 | 750 x 210 x 190 |

| All Function Sideseal Shopping Bag Making Machine | |||||||

| 32SWPFA-V | 3-30 | 3-30 | 30-110 | 0.012-0.15 | ±1 | 6.0 | 850 x 180 x 190 |

| 42SWPFA-V | 3-40 | 3-40 | 30-110 | 0.012-0.15 | ±1 | 6.7 | 850 x 210 x 190 |

| Model | Working width (mm) | Rewinding speed (M/min) | Power required (kw) | N. W. (kgs) | G. W. (kgs) | Machine dimension L x W x H (cm) |

| Automatic Sandwich Folding Machine | ||||||

| 1200SF | 400-1200 | 40-100 | 2.5 | 700 | 900 | 200 x 250 x 190 |

| 1600SF | 400-1500 | 40-100 | 3.5 | 850 | 1050 | 250 x 280 x 190 |

| Model | Film unwinding width (mm) | Gusset depth (mm) | Line speed | Film thickness (mm) | Power | Machine dimension L x W x H (cm) |

| Single Sheet Side Edge Heat-slit & Gusset Rewinding Machine | ||||||

| TR1300GT | 400-1200 | 85 | max.60 M/min | 0.03-0.1 | 5.0 | 450 x 200 x 400 |

| TR1600GT | 400-1500 | 85 | max.60 M/min | 0.03-0.1 | 7.0 | 450 x 230 x 400 |