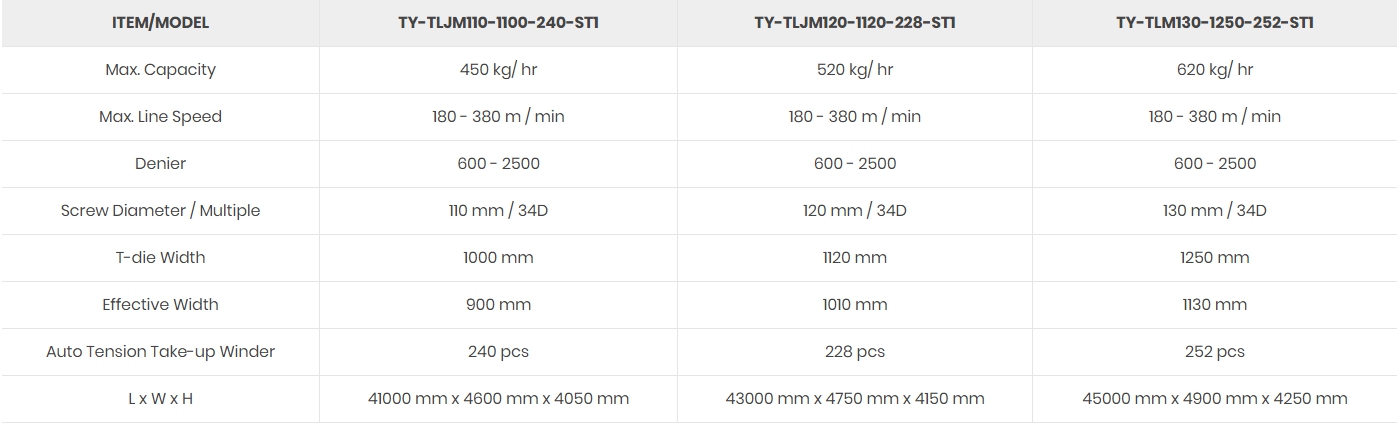

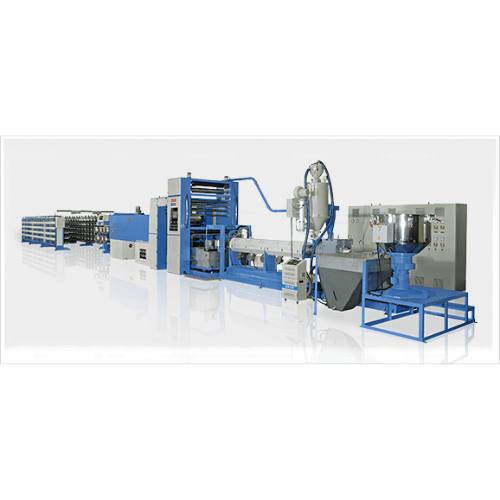

TLJM series is mainly used in PP & HDPE high denier tape production, it used for weaving by circular loom and flat loom into tubular jumbo bags, FIBC fabrics, tents, geotextiles and waterproof tarpaulin.

- Line speed: 180-380 m/mins

- Max. capacity: 620 kg/hr

- Special screw design to produce high quality and stable extrusion.

- Improve the physical property of tape to the highest tensile strength and tension.

- PLC programing and human machine interface with interlocking operation.

- Stretching oven with airflow and temperature stability design.

- Annealing pre-heater roller and cooling device makes the tape physical property stable.

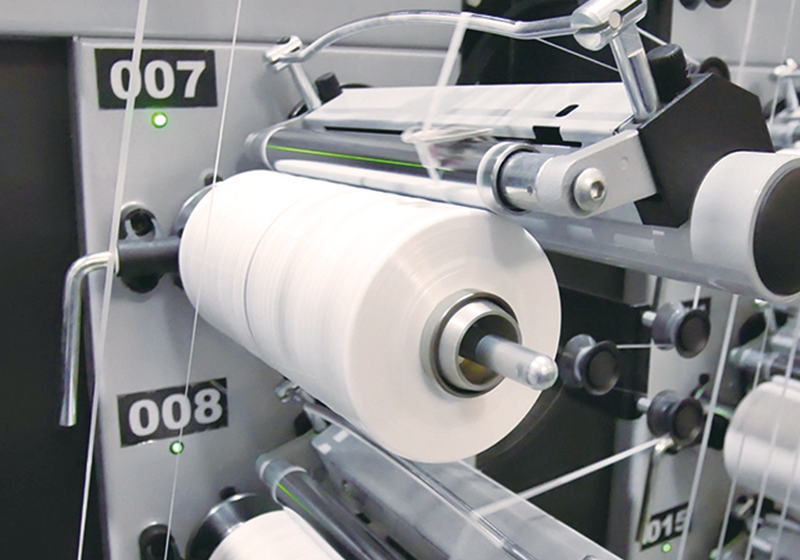

- Tape winder can set the diameter value of tape for winder change warning by LED light.

- Tape folding device as optional equipment.

- Machine customization

變頻式自動張力控制捲紗機,導紗滑座輕量化設計達到省電效能,捲紗軸附有勾紗裝置便利換捲。

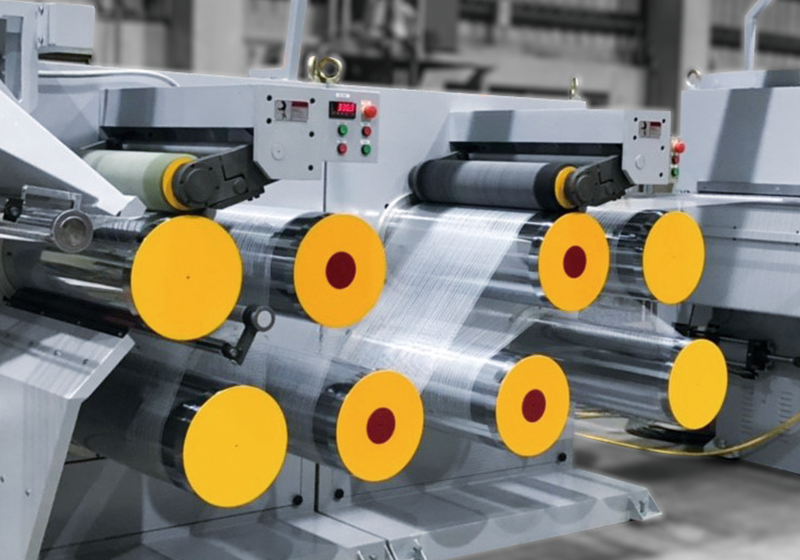

延伸烘箱內部經過風量整流與均勻加熱的設計,使得高丹尼紗達到延伸平均的效果。

延伸輪與預熱定型輪流程設計使高丹尼紗達到物性穩定的效果。

高丹尼紗採用前後兩組分條刀不停機設計與搖擺裝置,增加生產效率與延長刀片壽命。

水槽引取裝置,薄膜冷卻成型,除水系統,保持薄膜均勻平整。

雙層式自動換網裝置與T型模頭,模頭表面附保溫設計。

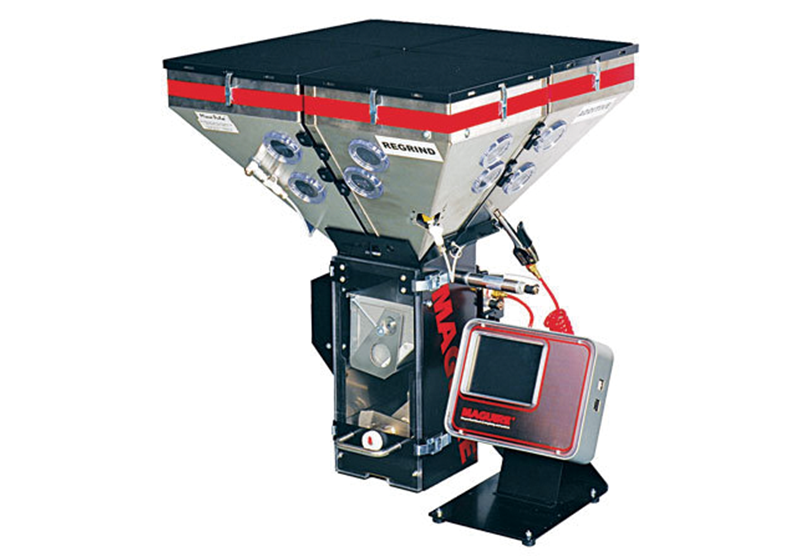

特寫照片 自動計量混合機(選擇設備),其功能是按設定原料比例自動精準下料與混合。