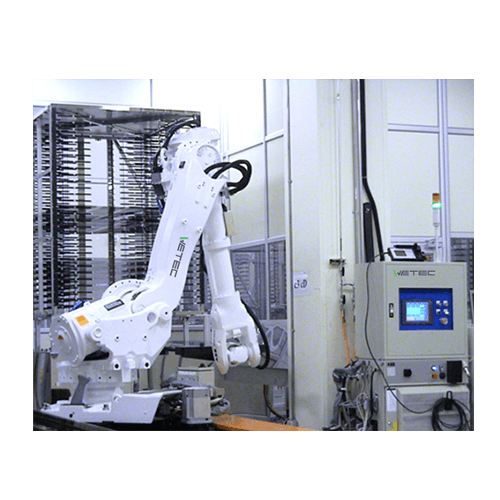

TFT-LCD基板移載系統整合

產品分類 : 工業機器人

· 玻璃基板移載系統 · 真空鍍膜Loading Unloading · CF Packing Unpacking · CELL段自動化移載 · 模組段製程自動化 · CF檢測移載自動化 · CIM軟體整合

多軸自動貼膜機 AFC-700LE

產品分類 : 切割機

Patented Bonding Mechanism: In achieving higher bonding accuracy and without air bubbles. Fully Automatic Tension Control System: The tension of materials for each axle is controlled in an automatic way. Servo Transmission Control: Dual-Axle servomotor is used to achieve synchronized alignment control. Diversified Size Option: The parameter fine-tuning can be executed according to the characteristics of different materials. High Clean Bonding Environment: Which meet high-cleanliness bonding space requirements in providing higher Y-Rate. Unique Material Handling Techniques: Which is designed according to the characteristics of optical film to avoid scratching the material.

全自動押出中空吹氣成型機 A 系列

產品分類 : 全自動中空成型機

此機種為風壓鎖模設計,簡易設計,生產快速,適合多種小容量產品或棒棒冰容器之生產。 螺桿驅動採變頻器搭配皮帶輪齒輪箱驅動馬達。 新型雙模頭生產設計。 機台鎖模成型方式為風壓驅動。可升級為油壓驅動(選配)。 移模方式為前後搖擺方式,成品由正前方下料槽取出。 獨立式電控箱搭配簡易式面板。 簡易型吹瓶機,適合初期較低資金投資生產。

橫走型機械臂TEM系列

產品分類 : 工業機器人

4站式2RT開模橡矽膠真空熱壓成型機 /VCC-F2

產品分類 : 壓縮成型機

產品特性 真空能力 真空度高,採平均抽法,可便品穩定,提高品質及產能。 開模設計 2RT 架構特點在於超越一般傳統前頂式掀模,可用於二層或三層模具之特殊功能,具有掀模及中層模具個別頂出之設計。此掀模功能具有分段掀模、分段中模頂出、連續掀模及中模頂出之軟體設計,可依操作需求作調整。

Master-batch-Feeder

產品分類 : 進料機

YR 多重崁入射出機圓盤系列

產品分類 : 立式射出成型機

Vertical clamping with vertical injection. Rotary table oscillate 180 °, rotate back / forth for easy loading and finished parts pick out, to increase productivity. Rotary table with location pin, accurate positioning for mold alignment and automation. Robot interface capability for complete automation. Standardized wtih 2-sation function, and capable for 3-station or 4-station function & automation linkup for advanced efficiency. Standardized wtih 3-column clamp, and available for 4-column clamp upon request.

SP-420 / 60205

Especially for bulky plastic products. Eliminate the disadvantages of traditional high horse power crusher.Also for cracking unusual objects,waste tyres,logs,sleepers,etc. ● 2-shaft,claw-cutter breaker has the best ability to shred anything with low noise,vibration free. ● Auto reversible equipment to prolong the life of machine.

半自動 - BOPP玻璃紙包裝機

產品分類 : 包裝設備

連續式壓空成型機-SL-1220

產品分類 : 真空成型機

● 高剛性機身設計: 一體成型的設計,並採用高張力鋼板製作而成,運行穩定,低噪音。 ● 四柱高剛性導柱機構: 導柱採用頂級鋼材製作而成,並搭配模座四柱結構,成型穩定,合模定位重現性高。 ● 伺服鍊條送料系統: 採用日製鍊條,搭配伺服控制,在高速送料的狀態下仍保有穩定精度。

INSERT INJECTION MOLD

產品分類 : 射出模具

INSERT MOLDING TECHNOLOGY: When a metal, plastic or ceramic part needs to be embedded in plastic to improve product structure it is called Insert Molding. It is a widely used process and one that YOMURA TECHNOLOGIES specializes in. With Insert Molding, a part is placed in a mold cavity then a selected plastic material is injected directly over it resulting is a single part with the insert(s) encapsulated by the material. This process normally uses engineering plastics for improved wear resistance, tensile strength and weight reduction. Insert Molding can be a highly efficient alternative to the assembly of discrete parts using soldering, connectors, fasteners, or adhesives. It also expands plastic capabilities and can reduce final product cost by limiting the amount of costly metal needed to create a part. And importantly, because we can use conventional single shot injection machines for Insert Molding, tooling costs are lower than with a multi-shot processing. Benefits: Reduced assembly and labor costs Because insert molding joins numerous components with thermoplastic, assembly and labor costs are greatly minimized. For example, a single stamping can be overmolded, then perforated to create multiple circuit paths. Reduced size and weight By eliminating fasteners and connectors, and by combining the physical strength of resin and metal inserts, insert molding yields smaller and lighter components. Increased reliability With every part tightly secured in thermoplastic, an insert molded component prevents part loosening, misalignment, improper terminations, and other problems. The thermoplastic resin also provides improved resistance to shock and vibration. Increased design flexibility Designers appreciate the virtually unlimited configurations that insert molding allows. For example, in creating a 3D circuit board, overmolding permits circuitry to move freely through the part, from inside to outside, up walls, down in holes-and the plastic ties it all together. Materials: Engineering plastic or Thermo Plastic Rubber (TPR) inserted with metal frame die casting, plated copper pin, sockets, wire frames, etc. Applications: TPR + Metal Frame(3C Mechanical Parts) ABS + Al. Die Cast (Sports/ Medical) Eng. Plastic + Patting Pin/Eng. Plastic + Wireframe (Connector) Eng. Plastic + Copper Pin/Contact (Precision Electronic Component)