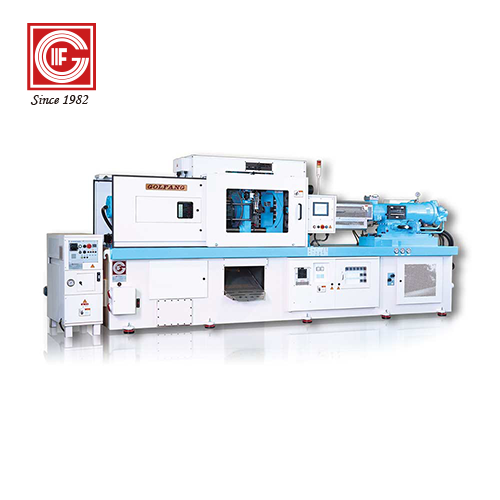

一段兩工位式射出吹瓶機 - IB 系列

產品分類 : 射出中空成型機

國鈁一步法射吹系列機種以風行世界的直壓式高級塑膠射出機為設計藍本,它鼎承直壓式射出機的堅固結構、高精密度、高穩定性及易操控、易維護、低運轉成本等諸項優點。

清潔水垢用酸劑 & 強力去油污鹼劑

DD除垢劑 專為淨化、預防水垢而使用,超濃縮的專利配方,可分解頑固水垢,能夠不停機操作的特性,既減少停機損失,又節省能源消耗。而 GC-S 則專治頑強的工業油汙,有良好的操作安全性與泛用性,可應用在各種材質上

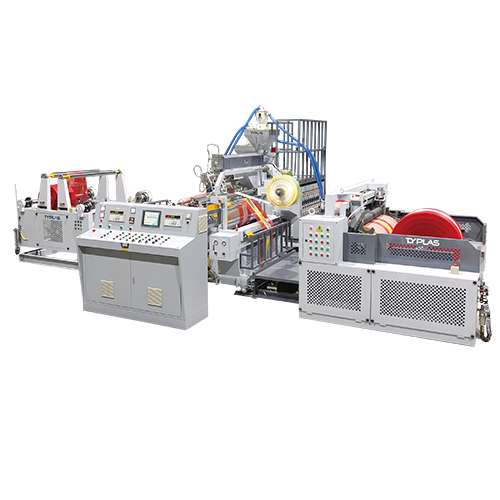

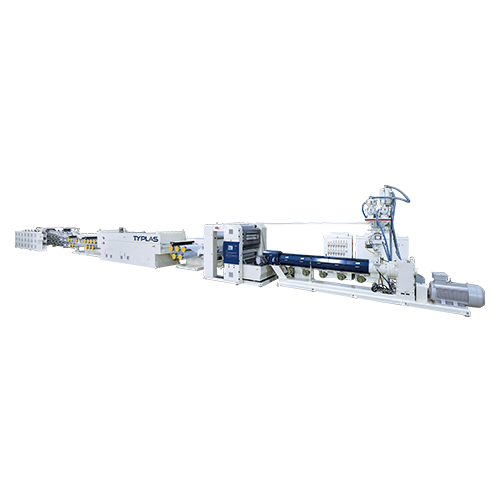

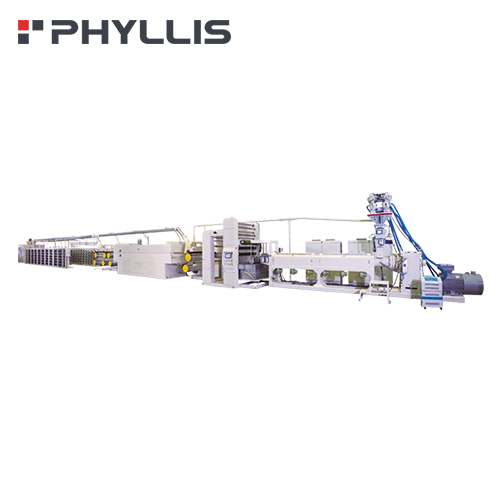

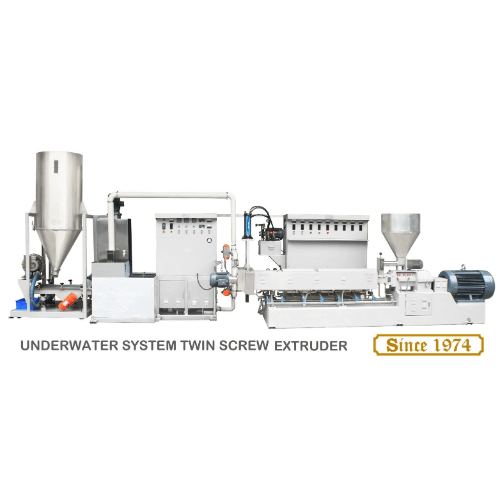

高填充量改質劑生產線

產品分類 : 混合物

高填料改性複合生產線(CaCo3,TiO2或滑石粉)我們的高填料改性複合生產線使用我們的擠出機械將不同類型的複合材料加工成粒料。我們簡單的操作線,包括一個分散捏合機和擠出機,以滿足您所有的具體化合物製作需求。 (高密度聚乙烯,再生高密度聚乙烯,二氧化鈦,滑石,PP + CaCo3等)我們也可以為您提供自動化生產線,並根據您的需要調整和定制設備。

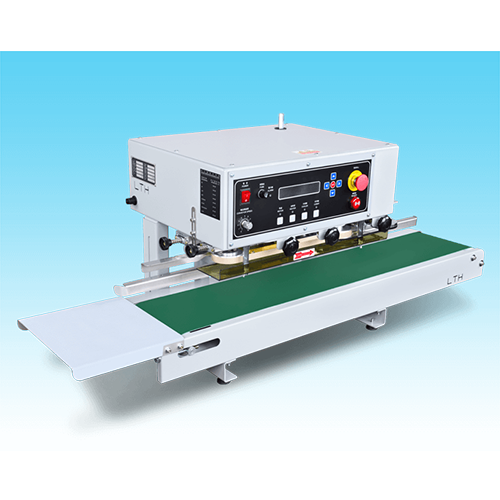

桌上型立式連續封口機 (SY – M904T)

產品分類 : 封口機

1.適用產品:食品纇、化工纇、五金零件。 2.適用包裝材質:任何可熱封之包裝材料。 3.封口包裝袋,從密著部外緣到袋口最長 35mm以內。 4. 臥式封口機無法封口作業的產品。 5. 內建計數裝置。 6. 內建異常警報裝置。 7. 內建速度顯示功能。 8. 內建2組溫度顯示,溫度控制更穩定及準確。 ※附加加裝設備: ‧不銹鋼(SUS#304) ‧ 5位計數器 ‧固體墨輪印字機(標示日期批號) ‧碳帶印字機(標示日期批號) 申裕

射出吹氣成型機 PK-IB 系列

產品分類 : 射出中空成型機

水中切雙螺桿塑膠造粒機

產品分類 : 造粒機

PET吹瓶機系列-TEM08S2-88

產品分類 : 全自動中空成型機

● Adopt the touch screen control system with 64K color and friendly PLC operation. ● Exclusively designed machine construction makes it convenient to combine the blow molding machine with conveyor system. ● The preforms are automatically arranged in order for feeding system at a single way and the dividing carrier is driven by a servo motor; this way will avoid preforms jamming, causing machine down or preforms waste. ● Adopt a servo control screw driving system; it is rapid, stable, clean and environmentally friendly. ● The preforms are fed into the heating system in a matrix mode and uniform heated by single-lamp with double-sided heating. ● Employ a single-lamp with double-side heating design and will save about 50% heating consumption compared with competitor method. ● With the temperature feedback function, temperature in the heating oven is automatically controlled by adjustment of infrared lamps to reduce prefrom crystallization problems. ● Specially designed heating box upgrade convenience of maintenance in changing infrared lamp and cooling ramp. ● The clamping mechanism is driven by a combination of servo motor and cam; this results in accurate and stable motion, low noise and minimal pollution. ● Utilizes the air recovery system and efficiency up to 50% so that the low-pressure air compressor will not be required. This will save equipment investment costs and energy consumption by up to 15%.