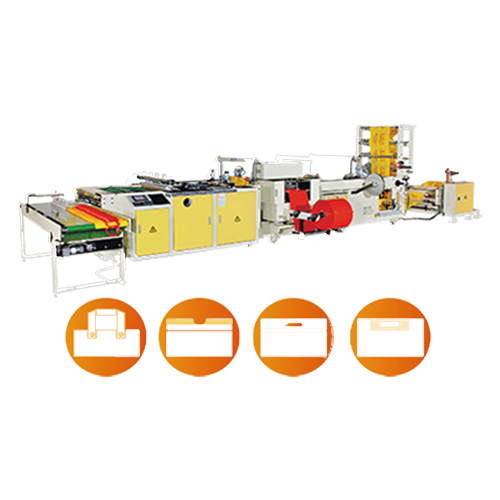

全自動側板製作機LY-800G

產品分類 : 塑膠袋製袋機

Introduction LY-800G is a high speed side gusseting machine. Its rotary-type unwind stand allows customer to make gusset at anywhere to avoid printing area.Servo-driven unwinding stand working with auto-tension control system allows customer to have stable and fast production. Features Servo motor for rewinding unit. Auto-tension control for rewinding stand. Rotary-type unwind stand. Auto-lifter for jumbo roll. Side-gusseting unit.

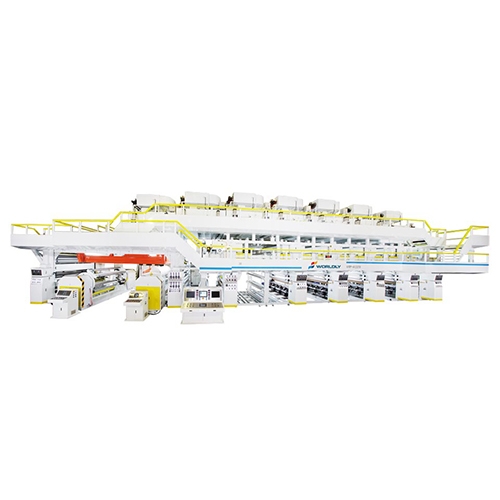

高速裝潢紙凹版印刷機

產品分類 : 凹版印刷機

此機型是由5色印刷座與1個塗佈座組成,適用於水性油墨之印刷,並應用於大寬幅的紙類,像是璧紙類、家具貼皮等。為節省成本考量瑋禮公司在熱能回收系統上採用特殊的熱導管裝置,更提升不少熱能回收的效率,在風箱內也採用義大利進口的紅外線加熱裝置,使得紙類的水性油墨印刷能夠完全乾燥,在全機驅動則採用日本住友重機SUMITOMO獨立馬達系統,本機也通過CE的認證標準於東歐生產。

Vibration Welding Machine HWV-M55LS

Vibration welding uses frictional heat to join the interface of two thermoplastic parts under mechanical pressure, the upper clipper clips the thermoplastic to do a high frequency reciprocating according the setting amplitude, it will have frictional heat generated to fully melt the interface, then stop moving and continued to put pressure and cooled to weld two thermoplastic parts

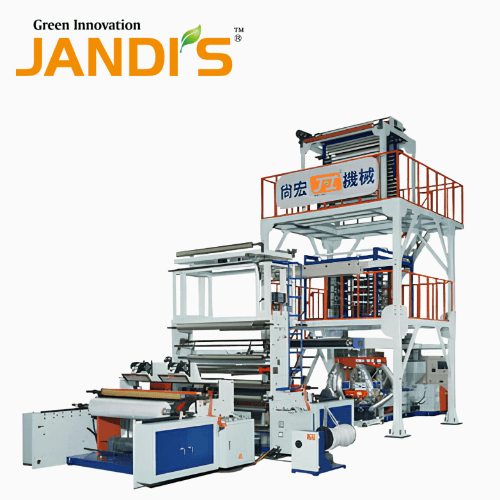

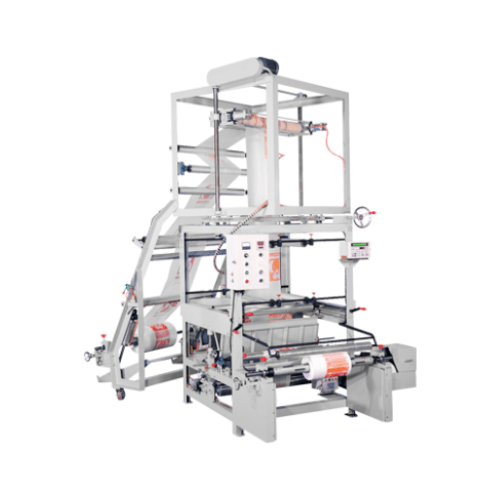

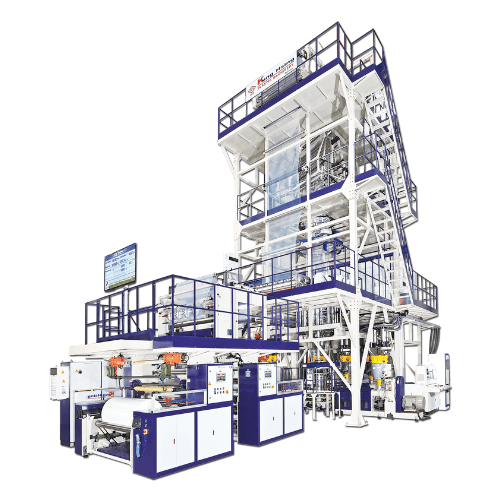

Five & Seven layer co-extrusion blown film line

產品分類 : 吹膜押出機

Five & Seven layer co-extrusion blown film line

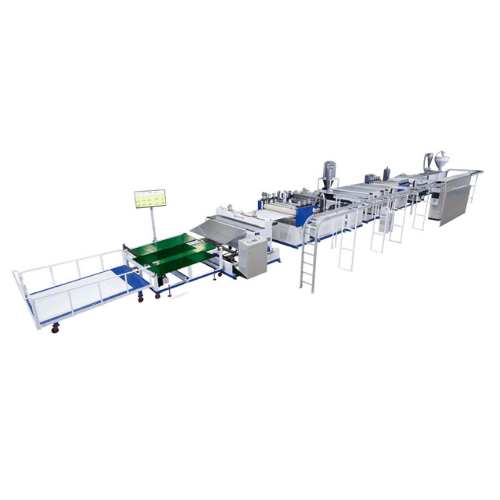

1600mm PP / PC中空板材押出生產線

產品分類 : 薄膜和片材生產線

For thirty years, Chi Chang has been designed and manufacturing fully computerised lines for sheet & film extrusion and co-extrusion. Our highly qualified team of engineers, operators and technicans has always been searching for high extrusion technology to meet your requirements. After years reserching since our first PP hollow profile sheet extrusion line in 1987, our new generation will produce PP hollow profile sheet with width from 1200mm to 2500mm, thinckness from 2mm to 10mm and output upto 500 kg/hr. In the mean time, we are pleased to introduce our new PC hollow profile sheet extrusion line. It is able to produce two-layer and three-layer PC hollow profile sheet with width 1200mm & 2100mm and thickness 5mm-10mm (two-layer) and 16mm (three-layer), and output upto 500 kg/hr.

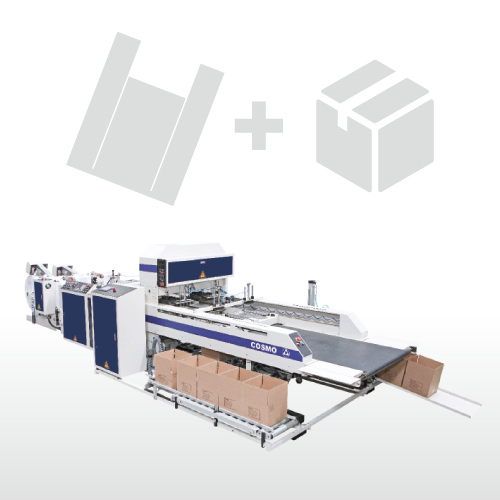

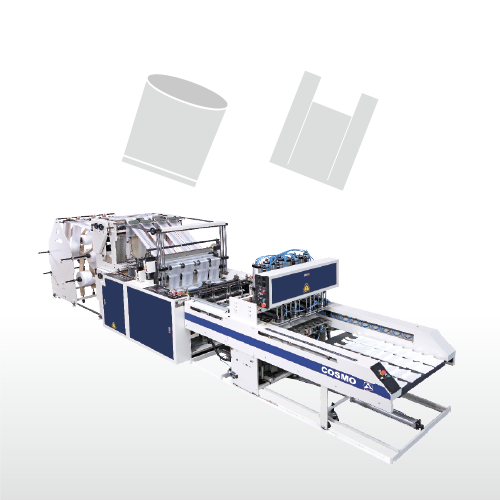

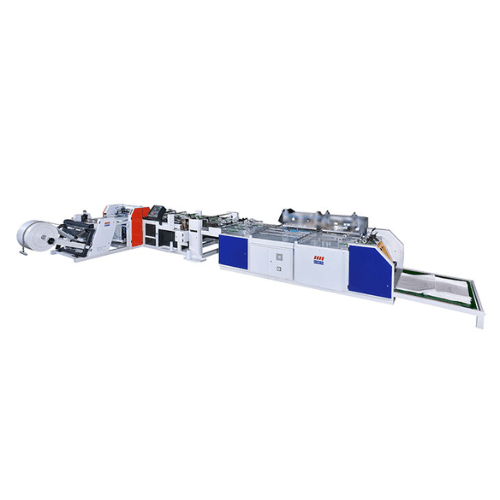

全自動4/6/8線背心袋&底封袋製袋機

產品分類 : 塑膠袋製袋機

Computer control over the entire process From film roll to final pruduct, one process flow Automatically stop when running out of film / film feeding blocks or jam

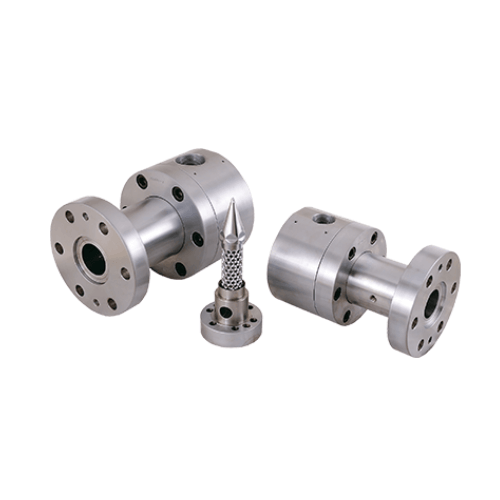

MACP200空氣調理器

產品分類 : 熱澆道系統

ARICO - 【閥門控制器】最佳解決方案: 長新科技(ARICO)與台灣橡膠/塑膠射出工業領域共存共榮,奠基自1987年以來的長年純熟製造技術,專注於工業控制儀器技術之研發與創新,特別擅長於精密「閥門控制器」相關產品之客製化製造生產。提供國內外廠商在「閥門控制器」產品上最方便的設定機制、穩定品質、合理價格,本公司除了累積長年客戶肯定推薦之「閥門控制器」相關產品外,持續以扎實研發技術 原理 為經營基礎,提供您在塑膠射出工業之溫度控制、位移感測、壓力傳感、射出機物聯網等精密工業控制上之最佳解決方案。

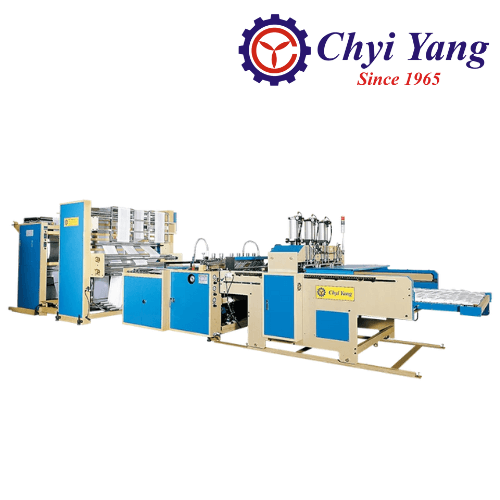

三線熱分條加折角背心袋製袋機

產品分類 : 塑膠袋製袋機

本機可將大尺寸的薄膜熱分條為3線,再通過折角裝置,成為3線印刷背心袋。 熱分條裝置可保持操作中之溫度穩定,以確保封口牢固。 配備日本進口伺服馬達及控制可提高產量及正確的袋長。 重料捲自動上料裝置以機械手臂取代人工上料,並備有氣壓軸使操作更簡便。 廢料輸送帶可將沖床沖出的廢料輸送至指定的位置。 成品對折裝置將整疊的背心袋對折以節省人工的作業時間。 我們亦有兩線的設備,麻煩聯絡我們以了解詳細規格

水冷式冷凍機 (YBW)

產品分類 : 冷卻裝置

Water Chiller (YBW ) Use the latest European, American or Japanese compressor, available in single and double compressors. The compressors of the double-compressor model can either run alone or together. High-efficient shell-pipe condenser which has heat-transmission function can save energy. Well-designed safety protection. It is also equipped with a digital temperature display indicator and abnormal warning indicators for the long lasting. Applied Machinery: oil temperature, ultrasonic ,high frequency machine/injection /extrusion/blow molding machine

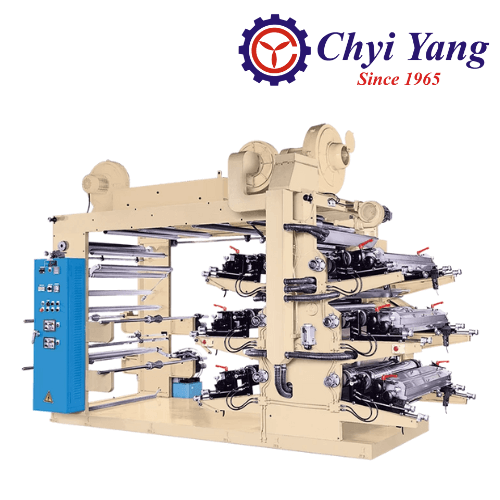

六色膠版印刷機(高速型)

產品分類 : 膠板印刷機

此機可印刷最多可印到四色,印刷組合為: 0+6、1+5、2+4、3+3 最高速度可達70-80 米/分鐘 印刷長度可達800mm,需要更長的印刷尺寸,麻煩詢問我們 配備對邊機(E.P.C.) 以下的規格並未展示所有型號,麻煩聯絡我們以詢問更大的印刷機

熱風乾燥箱 (YBO)

產品分類 : 乾燥機除濕機

應用於塑膠原料的乾燥,尤其在處理少量多樣或測試用之塑膠有其獨到的乾燥功能,可免除換料、清料之困擾,節省工時。而運用于塑膠成形後之回火處理,可增強韌性、消除張力,提升產品品質。 亦可運用於農產品(花粉、蒜頭、茶葉)或電子、電機、電鍍、製藥、烤漆、印刷等各行業相關產品之預熱或乾燥處理。 強力耐溫送風系列與獨特風路結構設計,確保內部的溫度分佈均勻準確、烘烤品質最值得信賴。 不銹鋼盤架與高效率之迴圈熱風回收再利用設計,省電、耐用,可同時乾燥多種塑膠,節省能源。 配有24小時自動計時裝置,可預先設定任何時間,予以乾燥。

伺服馬達驅動 三折點斷袋專用自動封切機+無芯捲取 自動換管機

產品分類 : 製袋機的應用

1. 單伺服馬達驅動、機體傳動輕快、穩定,全程製袋不停車。 2. 獨家設計之可調式萬用型摺袋裝置可摺三種樣式。 3. 可調式摺袋裝置可隨袋子大小直接調整無須更換任何摺袋架。 4. 本機器可生產無芯點斷捲取塑膠袋。 5. 專為有電腦操作障礙者所設計的人性化電腦操作面板,易懂易操作。 6. 電腦按鍵式製袋長度自動調整,出袋長度精準、廢料少。 7. 機器結構設計精簡、組裝精密,牢固耐用、保養簡易。 8. 操作簡便、封切口整齊美觀又牢固。 9. 電眼印刷追蹤、袋子印刷位置精準,當發現印刷失準機器自動停機。 10. 生產效率高,節省人力時間。

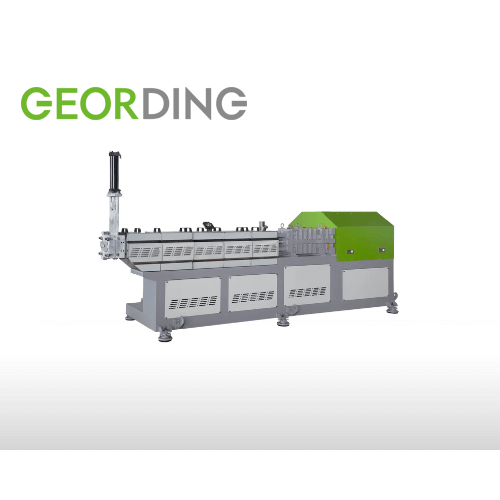

雙螺桿押出機

產品分類 : 製粒機

The twin-screw extruder, with its exceptional shearing performance and efficient melting capability, significantly enhances the stability of the plastic processing workflow while ensuring superior product quality. The screw elements can be flexibly adjusted to accommodate various raw materials. The special frame design and processing method ensure long machine lifespan and low maintenance costs. The advanced fully automated control system saves labor and allows for real-time monitoring and automatic adjustments. GEORDING Machinery has professional plant layout capabilities and can customize systems based on customer needs. This includes integrating upstream feeding systems, such as automatic weighing, and offering various pelletizing methods in the downstream, such as underwater pelletizing, strand pelletizing, and die-face pelletizing.

Hinged Container EG-66

產品分類 : 容器

Product Number: EG-66 Color: Natural Material: Fiber Shape: Clam shell

印刷電路板沖孔油壓脫料系統

產品分類 : 液壓沖孔機

富偉印刷電路板油壓沖孔脫料系統, 乃是空氣壓轉換為油壓動力源組合, 沖孔脫料台盤組合及快速換模系統等所組成, 而沖孔前壓板壓力及沖孔後油壓平均脫料之動作及出力可依不同材質來調整, 以達到業界追求高品質的要求。

Fully Automatic Bag Top Hemming Conversion Line (In-Line Process for Cutting-Sewing-Bag Top Hemming For Woven Bag) Model No: HEMITEC

Fully Automatic In-Line Process For Cutting-Sewing-Bag Top Hemming with 22~25 bags/min production capacity. (All-in-One Process from PP Woven Rolls into Finished Bags) Without Bag Top Hemming, the HEMITEC can process for Normal Cutting-Sewing Function with 38~40 bags/min production capacity. Experiencing Clean Process of Bag Top Hemming. Largely Reducing Hand-Touching on the Bag Top Area. Servo Driven Gripper Type Conveying Delivery, Ensuring Neat & Steady Bag Delivery. Saving Manpower and Saving Cultivated Training for Skilled Manuel Operators.

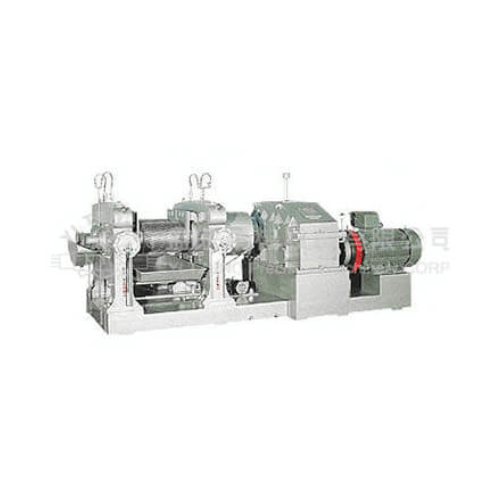

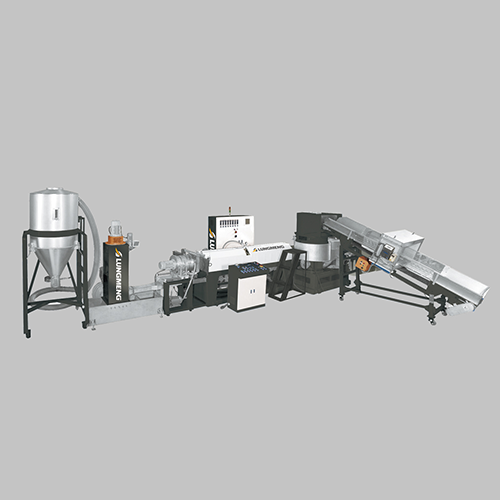

雙錐入料高速造粒整廠設備-水環切

產品分類 : 混合物

橡塑膠混合原料,適用於PVC, EVA, TPR, 碳酸鈣造粒、各種色母造粒、橡膠加硫、硫磺粒、分散劑……等 小馬力,大產能 耗電量小 容易清洗及換料 混合良好 水環切系統