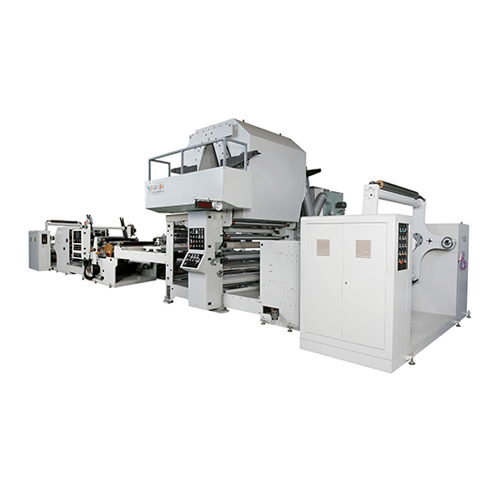

連續式(真空充氮)封盒包裝機

產品分類 : 中空包裝機

兆酆連續式真空充氮封盒包裝機為不銹鋼材質製造,真空室外安全蓋設計,開啟電器箱即斷電,安全性高,可一機多組不同規格模具使用,模具更換容易,多國語言且擺臂活動式的PLC人機觸控,方便360度操作,螢幕所有功能為文字敘述,方便操作者了解使用。真空 / 充氮、真空 / Skin Pack、封口包裝。且提供各式機器尺寸,以應不同大小尺寸的包裝盒需求。

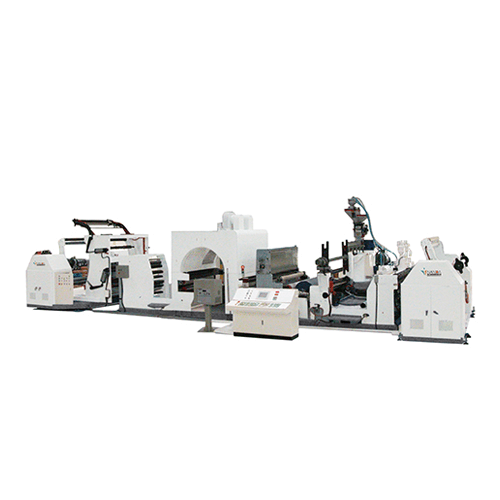

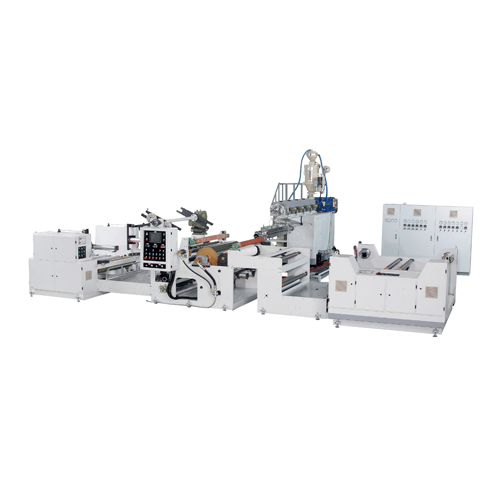

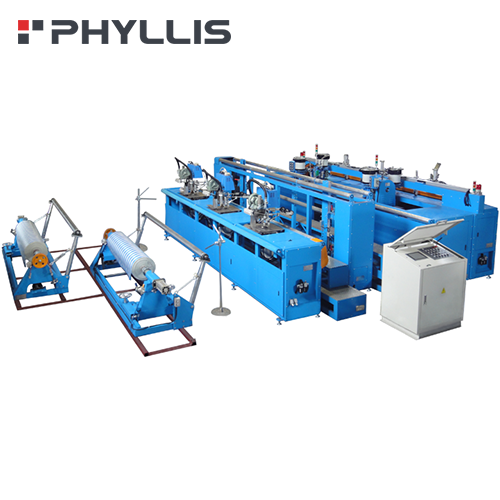

MULTIFUNCTION TWO-SHAFT TYPE SEMI-AUTOMATIC ALUMINUM FOIL & CLING FILM REWINDER (SRB-A-2S 20-50)

產品分類 : 分切機和複捲機

SRB-A-2S, the two shaft type semi-automatic, multiple functions rewinding machine Suitable for rewind aluminum foil and PE, PVC cling film. The mother roll available width is from 200-500 mm. The finished paper core’s I.D. is from 25-50 mm. This model is carried a brake system, controls the brake power accurately. Users can check the data of brake output and single product weight anytime. SRB-A-2S is able to set prior deceleration points of every speed level. Users only need to adjust rewinding speed afterwards. Machine will regulate deceleration points automatically by the settings. It has automatic functions of cutting and fixed length feeding. Users will thread the material onto paper core more convenient. The whole machine is combined of electronic control, carried with electric motor system; enable more precise and quicker shaft-changing movements. While finished rewinding process, the rewinding shaft will back off by itself. Users can switch to the automatic mode which start machine automatically after shafts are pressed down. Automatic cutting, automatic shaft-changing and shaft pressing, users just need to load & unload products after press start button. Welcome to consult machine with us. We will at your service.

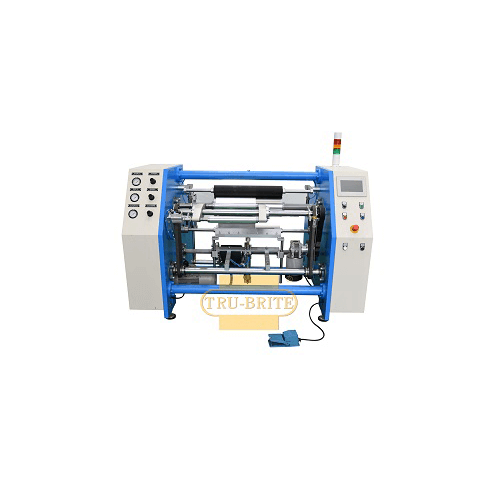

高速鋼模裁斷機 HSP-12

產品分類 : 發泡成型機

新型送料機構: 針對成型後材料高度不同設計了自動升降送料系統。 優越且安定的下死點精度: 採用雙軸同步機械結構,下死點穩定性高。 高精度深度調整機構: 採用左右同步微調機構,微調精度可達0.01mm。 參數儲存功能: 可將設定後之相關參數命名並儲存。 成型機連線功能: 成型機做同步控制進行連線作業。 自動潤滑機能: 全機採用了自動潤滑機構,減少了日常保養的工作。

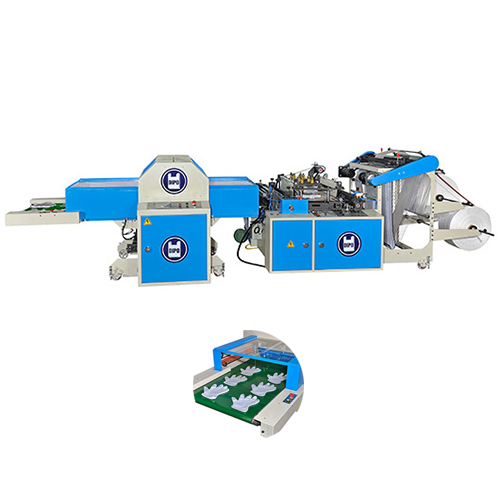

自動給袋包裝機

特徵 : 1. 本機械架台外部被覆SUS304不銹鋼製成,清洗方便,衛生美觀,適用容量於2KG以內,可配合自動計量機、液體、漿體充填機使用,操作簡單,調整方便。 2. 機械結構:經由自動送袋、開袋、充填、封口1、封口2、排出,一貫全自動操作。 3. 可另行加裝印日期機。 選購配備:充填機、計量機、輸送機。 可適用產品 : 粉體、液體、顆粒、醬體、粘體、糖果、米、糖、鹽、豆類、咖啡、肥料、冷涷食品、調味料、肉丸、咖哩醬、蕃茄醬、果醬、洗髮精、清潔劑、 蜜餞、飯類、液體與固體混合物。

Tooling Shop

產品分類 : 熱澆道系統

TOOLINGS FOR OPTIMAL PERFORMANCE AND RELIABILITY The core of the injection molding process is the tooling. In regard to their design and manufacture, the high-end machinery used is absolutely essential. This is why Yomura introduced a state-of-the-art and fully-automated system works 24/7 to fabricate the toolings and makes no compromises with respect to quality – and conceives and produces high-precision, custom made fast cycling injection toolings in house. MANUFACTURING CAPABILITY Tooling Automatic Fabrication Key points: All Process and measurement data are connected to minimize men key in error. All work piece are implanted with RFID chip to minimize men error. Pre-set 2D and 3D are used before and after process to ensure the work piece are manufactured to the 100% accuracy. Productivity will be expected to increased at least 30 % monthly.

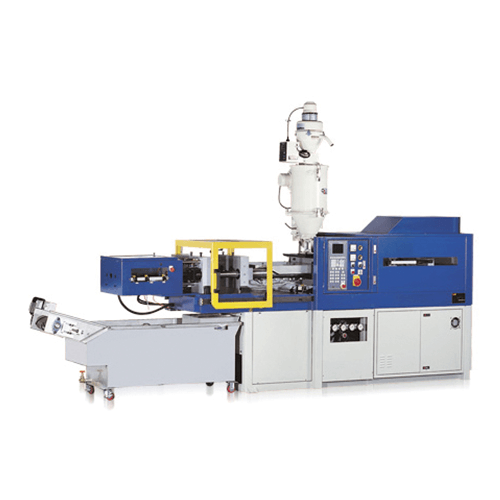

自動進針鞋跟機

產品分類 : 油壓夾模式射出成型機

● Rapid, high-precision direct hydraulic clamping system. Automatic needle loading, multistage ejection setting. ● Two adjustable nozzles with hot runners, molding 2 heels without runner in one shot.