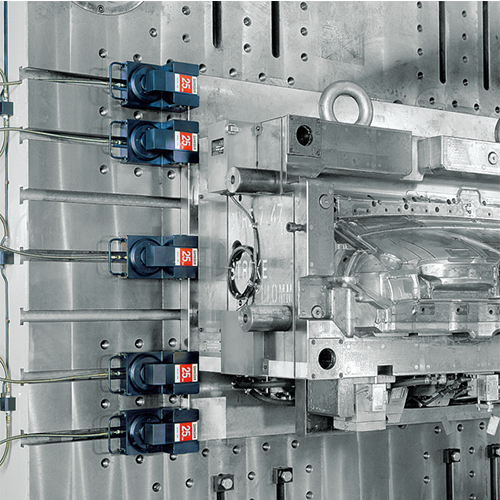

射出機、壓鑄機快速換模系統

產品分類 : 換模系統

產品簡介 迎接少量多樣高頻率換模生產型態的時代,爭取換模時效、確保操作安全—正是導入快速換模系統的最佳時機。 系統安全功能 各油壓迴路具有逆止防漏功能 此系統具壓降時自動補壓功能 各油壓迴路具低於安全壓力檢知功能,並與機台連線 夾模採對角交叉方向鎖模控制 操控具多項防呆功能

DOUBLE INJECTION MOLDING

產品分類 : 射出模具

Double Injection, sometimes known as 2 material 2 shot molding or 2K molding, is an innovative manufacturing process used to produce complicated molded parts from two different materials. Through a highly specialized and automated process we carefully control the injection of multiple materials, including two different kinds of resin, into a single, multi-chambered mold. Double Injection in performed on one machine that is programmed to perform two injections in one cycle. In the first cycle, a nozzle injects plastic into a mold. The mold is then automatically rotated and a different type of plastic is injected into the mold from a second nozzle. Double Injection Molding optimizes co-polymerization of hard and soft materials to create powerful molecular bond. The result is a single part with production and feature advantages. It can be used for a variety of product designs across all industries. It also allows for molding using clear plastics, colored graphics and stylish finishes which improves your product functionality and marketplace value.

捲取機

產品分類 : 分切機和複捲機

捲取機安裝在壓延機生產線上或各種材料的交換或復捲生產線的最終端,因應各種不同製品的捲取要求,我們的捲取機設備配有精密的調整裝置及簡易的操作,速度可以逹到200米/分,捲軸直徑最大可達1500mm,寬度最大可達6000mm。某些機型可以將薄膜的上部捲到捲軸的里面或外面,最後經過多次中間分切,可同一軸上捲取最多3個捲軸。薄膜的切割採用鍘刀式或剪刀式設計,通過驅動電機及控制系統,可以保証在高速狀態下片材捲取的最高張力精度。 捲取機的類型多樣,可依不同製品配置或定製。其中包括;自動中心捲取機(貼膠帶或免貼膠帶式)、自動單輪式表面捲取機、多輪式表面捲取機;適用子不同薄膜的專用導開機、復捲機和捲取機;輔助設備(修邊刀和中央切割裝置,缷捲和稱量機組,軸自動抽出裝置)等。

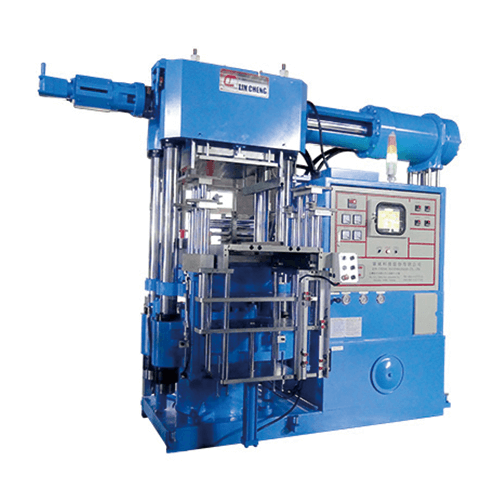

3RT開模橡膠射出成型機 IRH-S3

產品分類 : 雨靴注塑機

●開模設計 3RT 架構特點在於超越一般傳統前頂式掀模,可用於三層或四層模具之特殊功能,具有掀模及中層模具個別頂出之設計。此掀模功能具有分段掀模、分段中模頂出、連續掀模及中模頂出之軟體設計,可依操作需求作調整。 ●入料系統 特殊二段式入料設計,能使原料得到最佳排氣效果,又不死料之功能。 ●射出量控制 採高精密度德制光學尺設計,能準確的控制與計算射出量之大小。

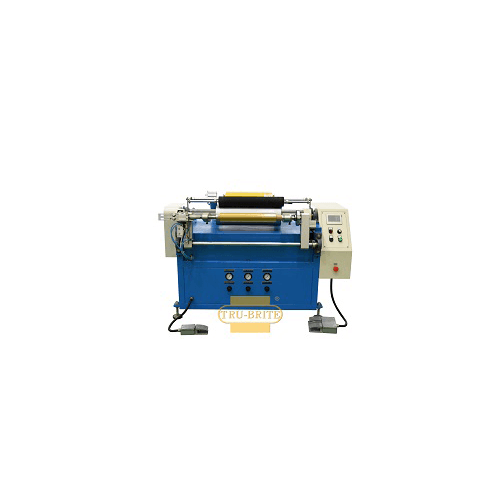

TWO-SHAFT TYPE SEMI AUTOMATIC CLING FILM REWINDER (SRS-2S 20-50)

產品分類 : 分切機和複捲機

SRS-2S, the two shaft type semi-automatic rewinding machine. It specializes in rewind PE, PVC cling film. The mother roll available width is from 200-500 mm, and the finished paper core’s I.D. is from 25-76 mm. SRS-2S has a knob for adjust rewinding speed. Users can choose convenient functions. Such as automated start after press down the rewinding shafts; or changes shafts automatically. The PLC unit wisely assists user to run the machine. Machine is carried pedal controllers which have 4 functions: Mother roll chuck switch / finished paper core switch / rewinding shaft pressing switch / start switch. Various pedal switches, more convenient operations. Welcome to consult machine with us. We will at your service.