THS 850/950單截

產品分類 : 工業機器人

•真空夾具電路。 •自動模式微修改。 •自動堆垛/碼垛。 •從模具的型芯/型腔側取出零件。 •拒絕零件/報警/操作歷史。 •站在模具上,等待外面的模具。 •錯誤的計數/分解歷史/操作記錄。

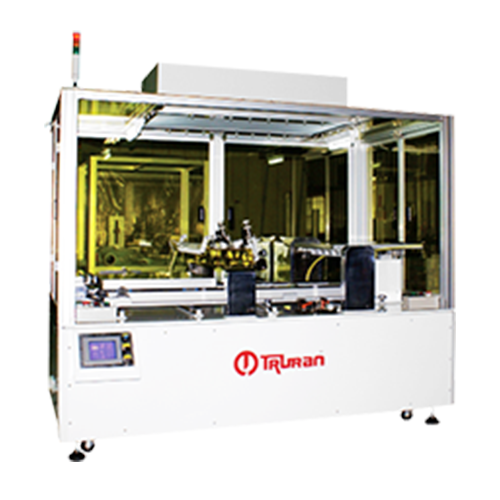

多軸自動貼膜機 AFC-700LE

產品分類 : 切割機

Patented Bonding Mechanism: In achieving higher bonding accuracy and without air bubbles. Fully Automatic Tension Control System: The tension of materials for each axle is controlled in an automatic way. Servo Transmission Control: Dual-Axle servomotor is used to achieve synchronized alignment control. Diversified Size Option: The parameter fine-tuning can be executed according to the characteristics of different materials. High Clean Bonding Environment: Which meet high-cleanliness bonding space requirements in providing higher Y-Rate. Unique Material Handling Techniques: Which is designed according to the characteristics of optical film to avoid scratching the material.

偏光板貼付機 GFL-20

產品分類 : 淋膜機

High Rigid Body Design: Higher workpiece machining accuracy. More stabilized bonding range. Higher accuracy. Smooth Bonding Process: The bonding process has been carefully designed in providing safe interlocking and higher yield rate. Automatic Film Stripping Mechanism (Optional): Automatic bonding film stripping mechanism in providing stabilized action and higher efficiency. Patented Bonding Mechanism: Special bonding mechanism is designed to achieve higher bonding accuracy and air bubble free effect.

高精度捲對捲自動送料裁斷機 TRC-350SP

產品分類 : 發泡成型機

裝軸同步送料機構: 雙軸同步送料提高了產出速度及良率。 優越且安定的下死點精度: 採用了矗霖特有之專利下死點機構,重複定位精度+\-0.005mm。 高精度深度調整機構: 採用高精度機構,微調精度可達0.01mm(0.001mm為選配)。 高效率增壓迴路: 較傳統迴路減少了30%以上之電力消耗。 光學材料對應: 可依照材料之特性做專用之搬送系統。 獨特的材料搬送機構: 高穩定性之伺服控制系統,不會汙染及刮傷材料。 自動潤滑機能: 全機採用自動潤滑機構,減少日常保養的工作。 廢料收捲機構: 裁斷加工後之廢料自動收捲,節省空間,提高作業性。

SINGLE-SHAFT TYPE SEMI AUTOMATIC CLING FILM REWINDER (SRS-1S 20-50)

產品分類 : 分切機和複捲機

SRS-1S One-shaft type semi-automatic rewinding machine. It’s suitable for rewind PE, PVC cling film. While it’s light and small, it can afford material width up to 200-500 mm, and the finished paper core’s I.D. from 25-76 mm. Users are able to set the timer of automatic back off after rewinding accord to their usage habits. Simple touch screen interface, easy operations. SRS-1S let users realize every function quickly. It reaches targets rapidly through simple operations. Welcome to consult machine with us. We will at your service

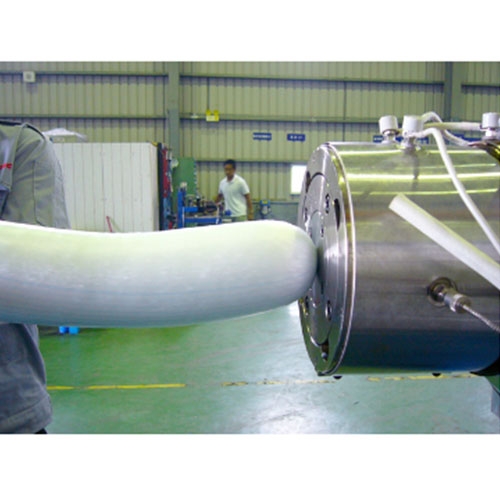

LDPE發泡管及棒材押出生產設備

產品分類 : 管材及異型材押出生產線

LDPE發泡管及棒材押出生產設備特色 : 透過正確調配樹脂及發泡劑的比例,本機器能提供最一致的配方。 能精準控制發泡劑注入量,並調節適當溫度,使發泡過程穩定。 操控安全性高,當馬達故障或壓力過高時系統會自動關機。

片材自動接合機 PTR-500

產品分類 : 淋膜機

Patented Automatic Receiving Mechanism: Performs the material jointing work automatically. Automatic Charging Mechanism: The vacuum robot is used to move the material to the designed position automatically. Servo Transmission Control: Uses 3-axle servomotor to perform high-speed transmission and positioning. Versatile Dimension Flexibility: The parameter fine-tuning can be performed according to the characteristics of different materials. Automatic Feeding Mechanism: Delivers the jointed material automatically. Parameter Storing System: Performs module-based memory for the production figures to facilitate the parameter management.

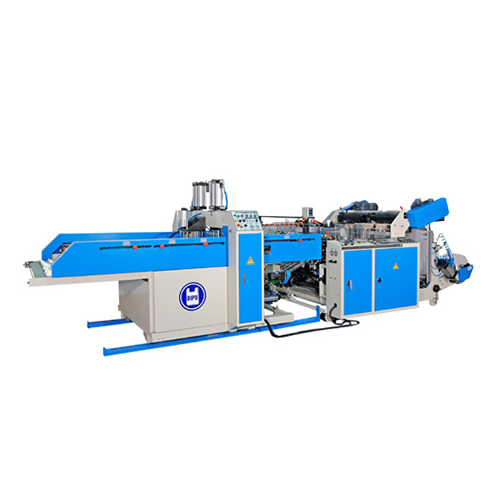

全自動高速四線T卹製袋機

產品分類 : 塑膠袋製袋機

DOUBLE INJECTION MOLDING

產品分類 : 射出模具

Double Injection, sometimes known as 2 material 2 shot molding or 2K molding, is an innovative manufacturing process used to produce complicated molded parts from two different materials. Through a highly specialized and automated process we carefully control the injection of multiple materials, including two different kinds of resin, into a single, multi-chambered mold. Double Injection in performed on one machine that is programmed to perform two injections in one cycle. In the first cycle, a nozzle injects plastic into a mold. The mold is then automatically rotated and a different type of plastic is injected into the mold from a second nozzle. Double Injection Molding optimizes co-polymerization of hard and soft materials to create powerful molecular bond. The result is a single part with production and feature advantages. It can be used for a variety of product designs across all industries. It also allows for molding using clear plastics, colored graphics and stylish finishes which improves your product functionality and marketplace value.