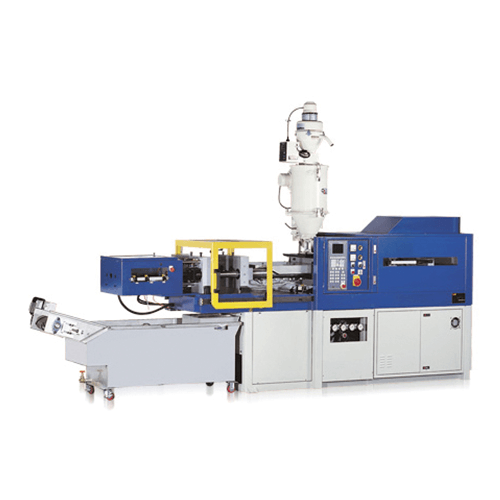

DOUBLE INJECTION MOLDING

產品分類 : 射出模具

Double Injection, sometimes known as 2 material 2 shot molding or 2K molding, is an innovative manufacturing process used to produce complicated molded parts from two different materials. Through a highly specialized and automated process we carefully control the injection of multiple materials, including two different kinds of resin, into a single, multi-chambered mold. Double Injection in performed on one machine that is programmed to perform two injections in one cycle. In the first cycle, a nozzle injects plastic into a mold. The mold is then automatically rotated and a different type of plastic is injected into the mold from a second nozzle. Double Injection Molding optimizes co-polymerization of hard and soft materials to create powerful molecular bond. The result is a single part with production and feature advantages. It can be used for a variety of product designs across all industries. It also allows for molding using clear plastics, colored graphics and stylish finishes which improves your product functionality and marketplace value.

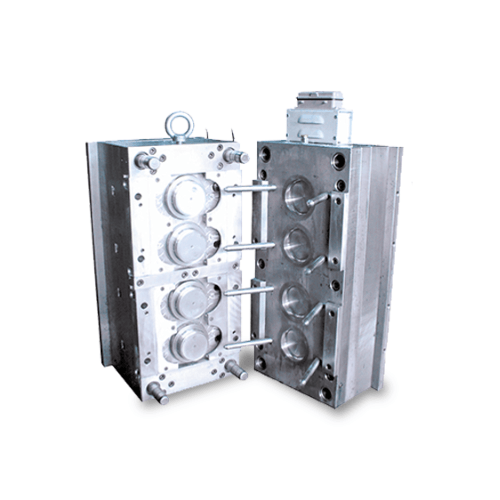

CONTRACT MOLD MANUFACTURE

產品分類 : 熱澆道系統

CONTRACT MOLD MANUFACTURE Yomura offers production molds that will be to customer’s facility or a manufacturing location designated. We manufacture molds for almost every major end market for plastics, like, housewares and delicate medical parts, aerospace parts, automotive parts or tiny parts for consumer electronics. All the molds are built to your specification, including type of steel, runner system, gate type, cavity materials and other features specified. Whenever the molds arrive at your facility, they can fit directly to your injection molding machines and are ready for production. ADVANTAGES Early involvement in design phase Ability to provide accurate and quick mold quote Low cost, quick build and high quality A price fully competitive with major mold makers around the global Long life-cycle and low maintenance Reliable delivery schedules Delivery of bug-free molds and ready for production as soon as arrival Complete integrated design and project management services Adapting the latest technology in design and advanced machine tools Ability to communicate quickly and efficiently, and easy to work with Close to superhighway, allowing for quick travel Service centers and international offices are available in major market countries Joint mold making operations with mold makers in other countries bring Yomura closer to the customers PROCESS FOR CONTRACT MOLD MANUFACTURE Customer supplies 3D CAD file to acquire quote Yomura starts the mold order process based on confirmation Yomura sends the 3D full mold design for your review and approval Yomura starts to build the injection mold upon approval Pilot and short production run after mold completion Sample approval Tooling delivery to location specified

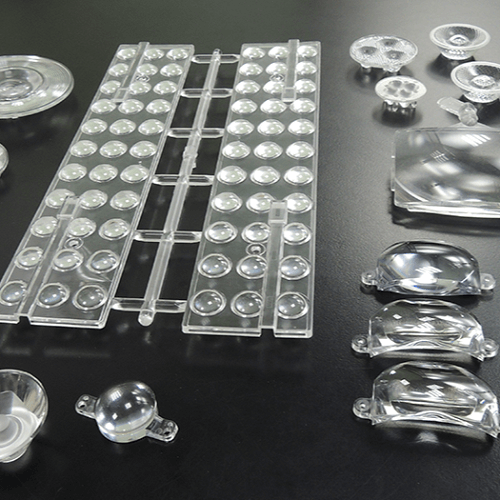

OPTICAL LENS & LED

Yomura Technologies is your source for high-end, polycarbonate optical LED lenses. Contact us for a complete catalog of LED Optical Lens options

2RT開模橡矽膠熱壓成型機 / HCC_D2

產品分類 : 壓縮成型機

產品特性 開模設計 2RT 架構特點在於超越一般傳統前頂式掀模,可用於二層或三層模具之特殊功能,具有掀模及中層模具個別頂出之設計。此掀模功能具有分段掀模、分段中模頂出、連續掀模及中模頂出之軟體設計,可依操作需求作調整。

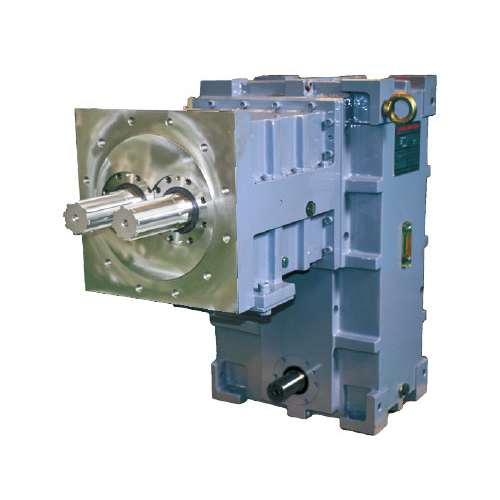

異向錐雙螺桿押出機齒輪箱

產品分類 : 齒輪箱

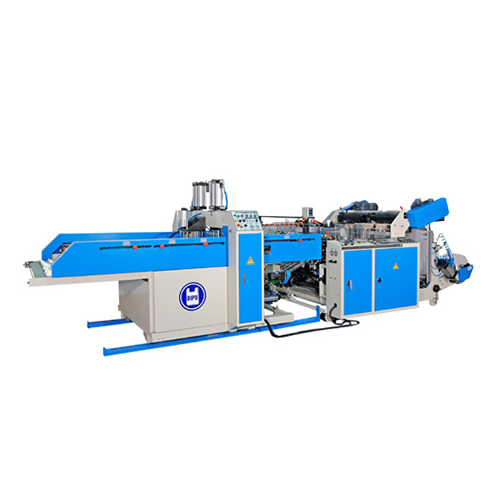

全自動高速四線T卹製袋機

產品分類 : 塑膠袋製袋機

自動進針鞋跟機

產品分類 : 油壓夾模式射出成型機

● Rapid, high-precision direct hydraulic clamping system. Automatic needle loading, multistage ejection setting. ● Two adjustable nozzles with hot runners, molding 2 heels without runner in one shot.

高精度自動送料裁斷機(捲對捲) APL-500SP

產品分類 : 發泡成型機

高精度的機體結構,可作全斷及半斷加工。 上下沖壓行程採用四柱高剛性導柱。 自動調刀機構,依設定自動調整,精度0.01mm。 高速多軸伺服控制系統,效能極高。 高階CCD對位系統,運作速度快,訂位精準。 裁斷主動力為高剛性凸輪機構,穩定性高。 安全防護裝置,確保人員安全(可選配CE架構)。

高精度小尺寸自動裁斷生產線-APL-300

產品分類 : 發泡成型機

●伺服裁斷機構: 裁斷主軸採用伺服馬達控制,高效率,高精度。 ●自動送料機構: 採用高階伺服控制,送料速度快,定位精準。 ●與多軸自動貼合機連線: 與RAL-400高精度多軸自動貼合機連線作同步加工。 ●與自動切片機連線: 與AC-300小尺寸切片機連線作切片加工。 ●二次加工對應: 可對應雙站對位裁斷加工。

UZSII-800W/1000W

產品分類 : 工業機器人

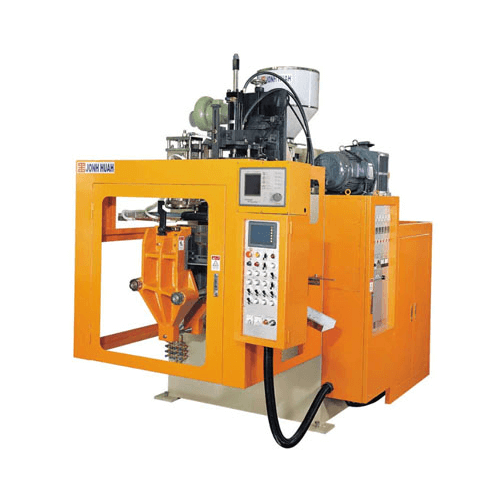

CT-ML系列吹袋機

產品分類 : 共擠吹膜機

Equipped with 2 extruders, A/B or A/B/A type blown film machine is able to produce two-layer film. Co-extrusion able to choose from AB to ABA, ideally for 2 layer film with different colour or apply CaCO3 in middle layer for cost saving, etc. Perfectly suitable to agriculture film, shipping bags, shrink film, consumer packaging and many others.

ABA三層共擠吹膜機

產品分類 : 共擠吹膜機

Nowadays, flexible packaging replaces the containers that need lots of energy to manufacture as like timber, paper boxes, glass and steel. Because flexible packaging has lower temperature required in processing than above materials, the emission of carbon dioxide can be reduced extremely. It is no doubt that development of flexible packaging becomes the new market trend currently. The usage of flexible packaging is covered in consumer and industrial goods, food, medical treatment and electronic products and it could be as prevention film, protection film, shrink film and so on. The flexible packaging industry emphasizes to how to downgauge the film structure and possess multiple different performances simultaneously. The multi-layer machines could be possible to achieve the expected outcome. The multiple materials in multi-layer machine could give different performances in each layer. Also, it could be more flexible to arrange the distribution of material that let users could manipulate the resins more extensive to reduce the cost in material and production. In current time, at the issue of sustainability, people pay attention to the possibility in recycling to reuse and biodegradable material development. In the flexible packaging industry, it is an opportunity and a challenge for each manufacturer to realize high-performance film, at the same time, to save energy and to be friendly to environment . Please feel free to contact us and tell us the information about the film, King-Plus will provide a tailor-made blown film machine to your requirement.

專業IMD模內裝飾整廠輸出

產品分類 : 注塑模內貼標射出成型機

• Total Solution For In Mold Decoration Technology. • Environment-friendly plastic decoration process - IMD/FIM/IML. (In-Mold Decoration / Film Insert Molding / In-Mold Labeling) • Product: Housing/casing of mobile phone, mp3/mp4, GPS, Lab-Tab Computer, 3D Labeling of Electric Goods;Automotive Dashboard Meters, Controllers, and Interior Decorative Items; the fancy colored Plastic Body Parts of Motorbike,...etc.

UNB 系列-1300-1800

產品分類 : 工業機器人

高精度捲對捲自動送料裁斷機 TRC-350SP

產品分類 : 發泡成型機

裝軸同步送料機構: 雙軸同步送料提高了產出速度及良率。 優越且安定的下死點精度: 採用了矗霖特有之專利下死點機構,重複定位精度+\-0.005mm。 高精度深度調整機構: 採用高精度機構,微調精度可達0.01mm(0.001mm為選配)。 高效率增壓迴路: 較傳統迴路減少了30%以上之電力消耗。 光學材料對應: 可依照材料之特性做專用之搬送系統。 獨特的材料搬送機構: 高穩定性之伺服控制系統,不會汙染及刮傷材料。 自動潤滑機能: 全機採用自動潤滑機構,減少日常保養的工作。 廢料收捲機構: 裁斷加工後之廢料自動收捲,節省空間,提高作業性。

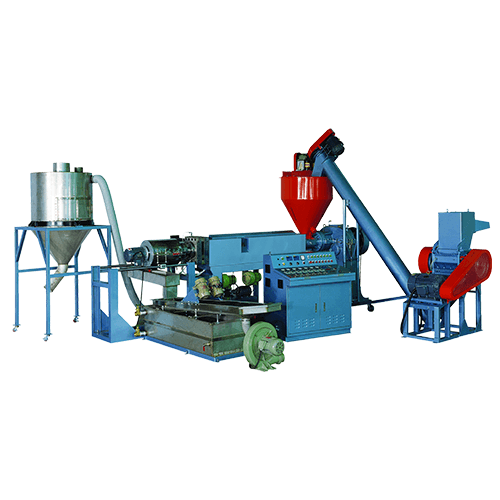

環保型雙機直結模頭切膠粒製造機(水冷式)

產品分類 : 製粒機

• 型號: TY-LBW 系列 • 產地: 台灣 • 適用樹脂: PP,PE,ABS,PS,HIPS. • 特殊使用樹脂: POM,PC,ACRYLIC • 產能: 100~800 kg/小時

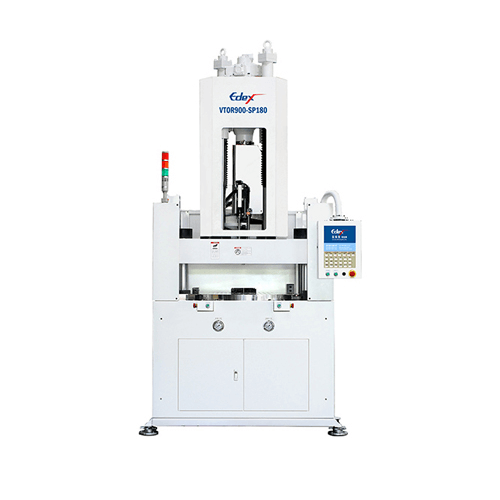

VTOR 系列 精密立式轉盤射出機

產品分類 : 全自動射出機

● 創新設計轉盤面積最小,容模尺寸最大 ● 可搭配柱塞式或螺杆式射出 ● 專利設計輔助進料系統,貯料跟臥式機一樣精准 ● 兩板直壓式四缸鎖模機構 ● 專利輻射式力學範本耐用30年 ● 安全光柵保護裝置 ● 智慧程式控制系統讓射出更容易 ● 相對同規格機型,機台高度低 ● 符合人體工學的工作臺高度 ● 電腦控溫氣冷式油冷卻系統 ● 精密節能油電伺服系統

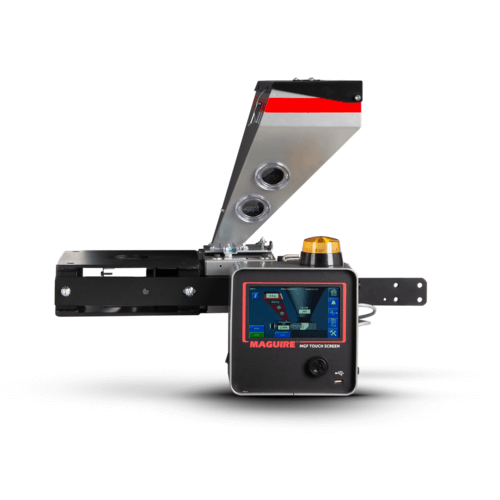

秤重式側餵料機(色母機)

產品分類 : 配料設備

MGF重力計量餵料器 強大的硬體,並與行業領先的軟體控制整合在一起,以實現持續精確的計量餵料精度。 獨特的雙稱重傳感器技術 設定1%時計量精度大約為±0.2% 餵料器適合射出成型和押出工藝

EPE 發泡管、套角押出機系列

產品分類 : 發泡機

高精度CCD自動對位裁斷機-APL-500CCD

產品分類 : 發泡成型機

●高精度的機體結構,可作全斷及半斷加工。 ●上下沖壓行程採用四柱高剛性導柱。 ●自動調刀機構,依設定自動調整,精度0.01mm。 ●高速多軸伺服控制系統,效能極高。 ●高階CCD對位系統,運作速度快,訂位精準。 ●裁斷主動力為高剛性凸輪機構,穩定性高。 ●安全防護裝置,確保人員安全(可選配CE架構)。

PP打包帶生產線(JC-SPP系列)

產品分類 : 膠帶押出機

JC-SPP系列PP捆紮帶擠出生產線設計用於製造PP聚丙烯帶,通常用於輕至中等負荷的包裝,例如報紙和雜誌,紙箱,棧板以及其他工業和消費者用途。

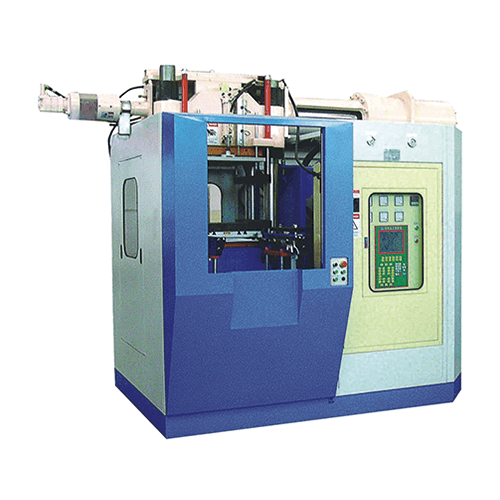

CE認證橡膠射出成型機 IRH(CE type)

產品分類 : 雨靴注塑機

Material supply system A special design of two-stage material supply is adopted. It expels bubbles out of the raw material in the most effective way and there is no dead material.