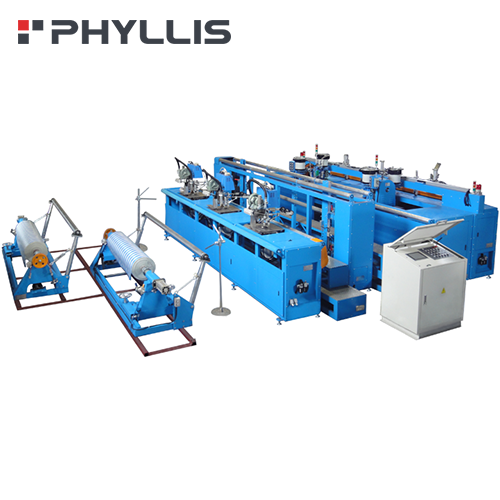

高精度小尺寸自動裁斷生產線-APL-300

產品分類 : 發泡成型機

●伺服裁斷機構: 裁斷主軸採用伺服馬達控制,高效率,高精度。 ●自動送料機構: 採用高階伺服控制,送料速度快,定位精準。 ●與多軸自動貼合機連線: 與RAL-400高精度多軸自動貼合機連線作同步加工。 ●與自動切片機連線: 與AC-300小尺寸切片機連線作切片加工。 ●二次加工對應: 可對應雙站對位裁斷加工。

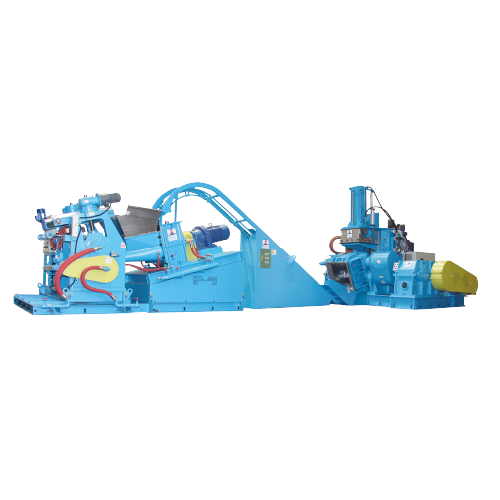

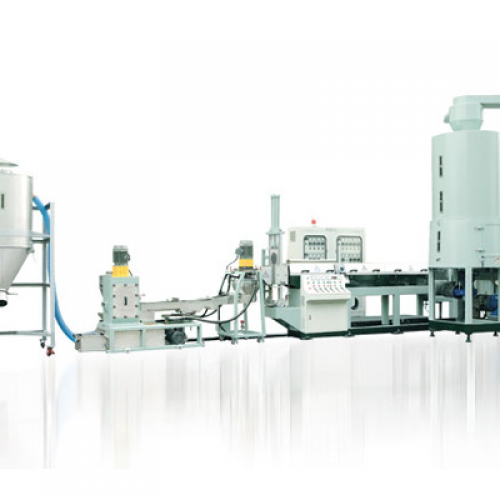

環保型塑料回收押出機系列(水冷式)

• 型號: TY-LW 系列 • 產地: 台灣 • 適用樹脂: PP,PE,ABS,PS,HIPS. • 特殊使用樹脂: POM,PC,ACRYLIC

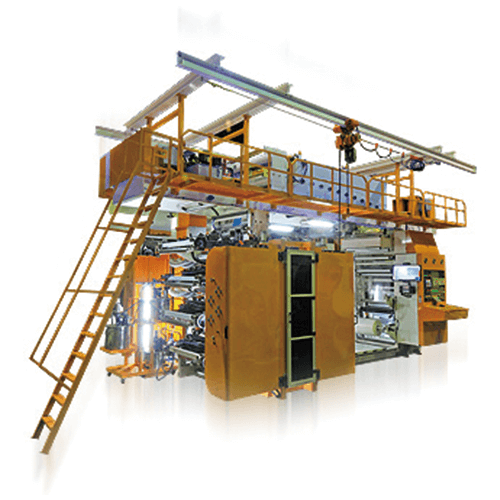

Flexojet (進階CNC色座控制機型 )

產品分類 : 膠板印刷機

Flexojet為齒輪式印刷機,但在印刷座上配備了伺服馬達,讓您可以提高印刷精度。此印刷機在一定的速度規範之下,產出高質量的打印品質。若您正在尋求一一款輕量級解決方案,但擁有先進的CNC印刷座控制系統,您可參考此印刷機來客製。

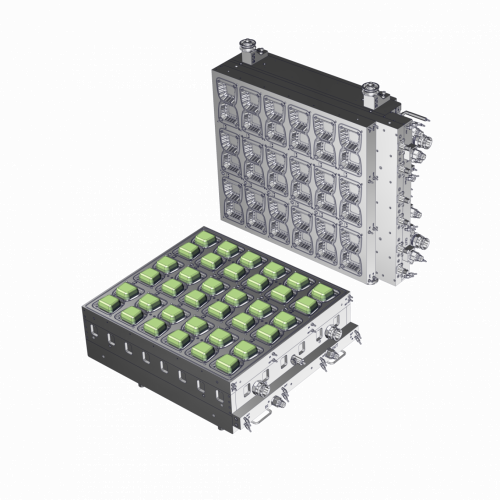

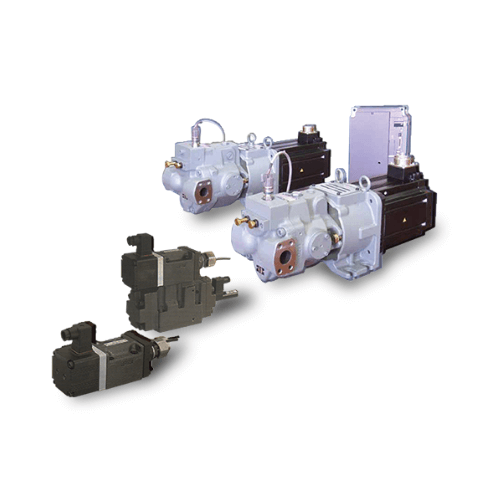

Servo-Motor-System

產品分類 : 馬達

HP-FG800-8SP-200

產品分類 : 膠板印刷機

尼龍 66 工程塑膠 - NB1200G33

產品分類 : PA樹脂/尼龍

33%玻璃纖維增強 (本色-高流動性) 應用說明:手工具、電動工具、園藝工具用,汽車、機車、腳踏車零組件用,運動器材零組件用,電子、電器外殼及零組件用,O.A.辦公室零組件用,水資材用,醫療復健器材。

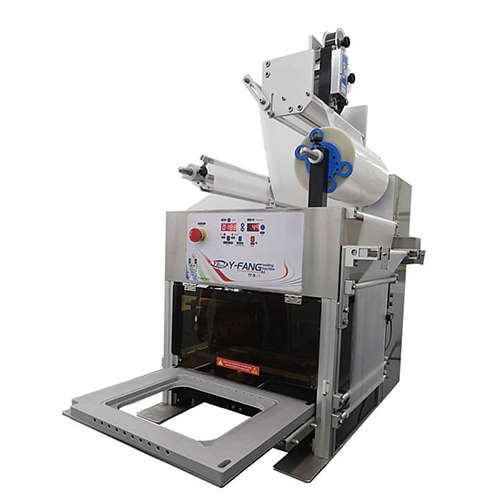

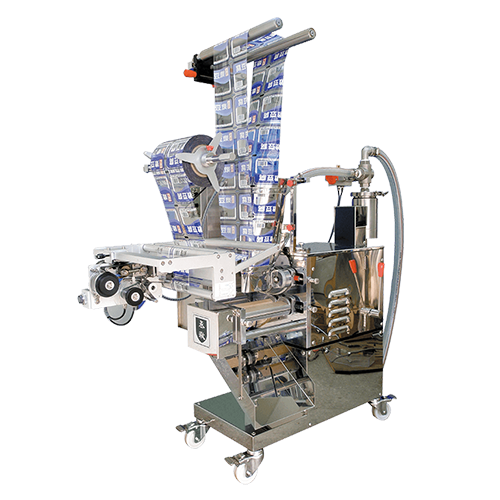

液體、高濃度包裝機 - TYPE-857

產品分類 : 液體包裝機

• 適用產品 : 液體包裝 : 茶、果汁、水、洗髮精、醬油、沐浴乳、液體調味醬等無雜質之液體物品。 高濃度包裝 : 珍珠粉圓、奶油、果醬、沙茶醬、肉燥、沙拉、洗面乳、面膜醬、辣椒醬、番茄醬、牛油等濃稠有雜質之高濃度物品。 • 機器功能 : 自動製袋→計量→下料充填→封合→切斷→成品送出。 • 包裝材質 : 尼龍紙+PE、OPP+PE、等其他各種液體熱封的包裝紙。

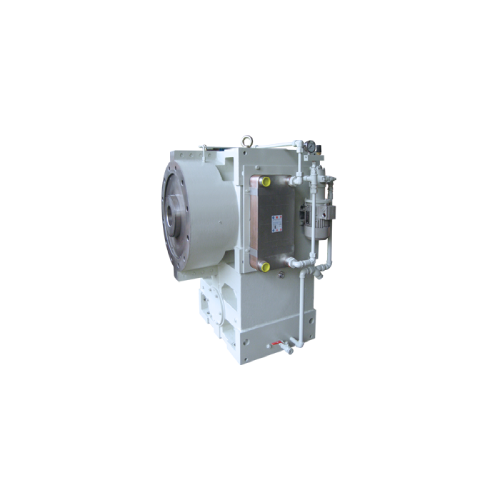

押出機專用齒輪減速機

產品分類 : 齒輪箱

CASE Material: FC 25 module cast iron GEAR SHAFT a. Material : SNCM220.Carburization & Hardness HRc56∘~60∘ b. Gear precision: reach JIS 2 level GEAR Material: SCM420 Carburization & Hardness HRc56 ∘ ~58∘ b. Gear precision: reach JIS 2 level OUTPUT SHAFT Material: SCM440 Hardness: reach HRc28 ∘ ~32∘ High Frequency Heat Treatment in HRC 48〫-52〫 in the connected area of Oil Seal Bearing Brand : SKF 、FAG、NSK (OPTION), Oil Seal : NOK or SKF Brand, material: Viton Lubrication System : OIL BATH SPLASH TYPE Forced type (Elements including as below) Motor PUMP(1HP/220/380V+Rop210HA) Teco Brand Cooling device(plate type) or Cylinder type Y Type Filter Temperature Gauge Pressure Gauge Pressure Switch Gear Measuring Report : Lead/Profile/Pitch testing Report Operation temperature rising: below +40 ℃ (Ambient temperature) Operation Vibration < 2.3mm/sec Operation Sound < 80Db, None Oil Leakage

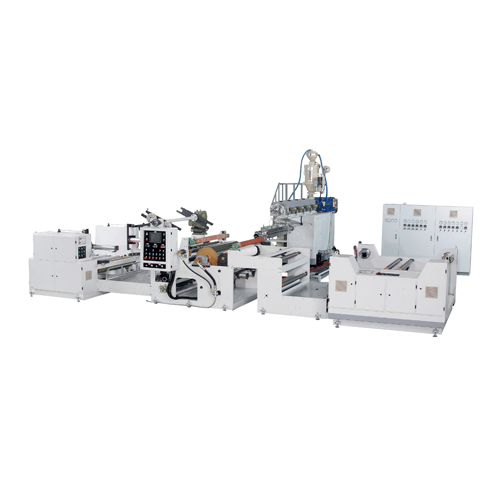

3D印材抽條押出設備

產品分類 : 長絲與紗線押出生產線

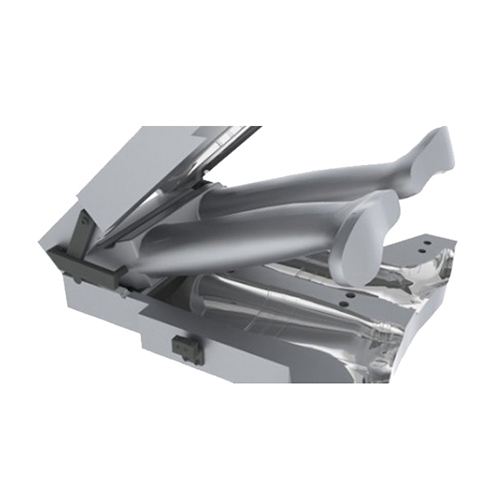

METAL INJECTION

產品分類 : 射出模具

Metal injection molding (MIM) is a metalworking process by which finely-powdered metal is mixed with a measured amount of binder material to comprise a ‘feedstock’ capable of being handled by plastic processing equipment. This is cost-effective for small, intricate, high-volume products which would otherwise be quite expensive to produce by alternate or classic methods. Mold Interconnect Device (MID) integrates a circuit into a plastic part reducing weight and dimensions. We use an innovative assembly process: from injected mold to laser etching then plating with copper or gold. APPLICATIONS Mobile phone’s aerial circuit Medical audiophones Automotive steering wheel Position sensor

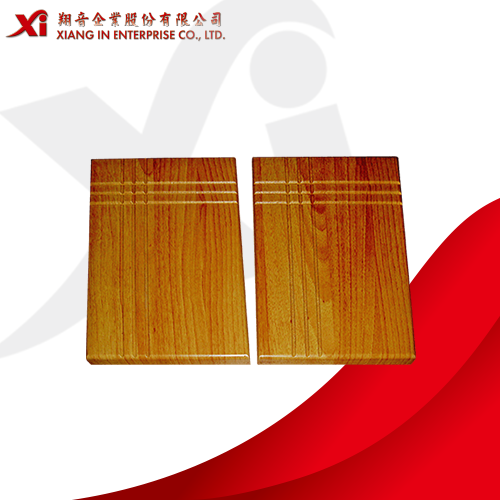

木材材質專用熱轉印膜

產品分類 : 薄膜

各類塑膠製品、布丁桶、容器、金屬外殼、家用品、文具用品、禮品…等多項商品。 透過翔音高品質的熱轉印膜與熱轉印技術,最適合將精美的圖樣印製在木質材料上。熱轉印具有直接印刷無法達成的多項功能,利用熱轉印膜與熱轉印機將精美圖案轉到產品上,適用各種材質,可提升產品的附加價值,降低成本,增加利潤。

尼龍 6 工程塑膠 - NAH1200G20

產品分類 : PA樹脂/尼龍

20%玻璃纖維增強 (本色-超韌耐衝擊) 應用說明:手工具、電動工具、園藝工具用,汽車、機車、腳踏車零組件用,運動器材零組件用,電子、電器外殼及零組件用,O.A.辦公室零組件用,水資材用,醫療復健器材。

CONTRACT MOLD MANUFACTURE

產品分類 : 熱澆道系統

CONTRACT MOLD MANUFACTURE Yomura offers production molds that will be to customer’s facility or a manufacturing location designated. We manufacture molds for almost every major end market for plastics, like, housewares and delicate medical parts, aerospace parts, automotive parts or tiny parts for consumer electronics. All the molds are built to your specification, including type of steel, runner system, gate type, cavity materials and other features specified. Whenever the molds arrive at your facility, they can fit directly to your injection molding machines and are ready for production. ADVANTAGES Early involvement in design phase Ability to provide accurate and quick mold quote Low cost, quick build and high quality A price fully competitive with major mold makers around the global Long life-cycle and low maintenance Reliable delivery schedules Delivery of bug-free molds and ready for production as soon as arrival Complete integrated design and project management services Adapting the latest technology in design and advanced machine tools Ability to communicate quickly and efficiently, and easy to work with Close to superhighway, allowing for quick travel Service centers and international offices are available in major market countries Joint mold making operations with mold makers in other countries bring Yomura closer to the customers PROCESS FOR CONTRACT MOLD MANUFACTURE Customer supplies 3D CAD file to acquire quote Yomura starts the mold order process based on confirmation Yomura sends the 3D full mold design for your review and approval Yomura starts to build the injection mold upon approval Pilot and short production run after mold completion Sample approval Tooling delivery to location specified

曲肘式伺服節能射出成型機-Servo 90E – Servo 570E

產品分類 : 臥式射出成型機

● Effective Energy Saving Unit ● Outstanding Hydraulics ● ASE Servo Pump

一般-自動液劑灌裝設備-充填 - AF-80

此液體灌裝設備主要用於容量大於60mL低黏度的液體產品,例如膠原蛋白健康飲品,漱口水..等等 此外可根據產品的不同特性 適度修改設備配合產品使用。

Vacuum Packaging Machine (GD900)

產品分類 : 中空包裝機

Power:AC220V3Φ Machine Size:1020x740x1080/mm Chamber Size:960x620x180/mm Sealing length:900mmx2

三層共擠吹膜機

產品分類 : 共擠吹膜機

Nowadays, flexible packaging replaces the containers that need lots of energy to manufacture as like timber, paper boxes, glass and steel. Because flexible packaging has lower temperature required in processing than above materials, the emission of carbon dioxide can be reduced extremely. It is no doubt that development of flexible packaging becomes the new market trend currently. The usage of flexible packaging is covered in consumer and industrial goods, food, medical treatment and electronic products and it could be as prevention film, protection film, shrink film and so on. The flexible packaging industry emphasizes to how to downgauge the film structure and possess multiple different performances simultaneously. The multi-layer machines could be possible to achieve the expected outcome. The multiple materials in multi-layer machine could give different performances in each layer. Also, it could be more flexible to arrange the distribution of material that let users could manipulate the resins more extensive to reduce the cost in material and production. In current time, at the issue of sustainability, people pay attention to the possibility in recycling to reuse and biodegradable material development. In the flexible packaging industry, it is an opportunity and a challenge for each manufacturer to realize high-performance film, at the same time, to save energy and to be friendly to environment . Please feel free to contact us and tell us the information about the film, King-Plus will provide a tailor-made blown film machine to your requirement.

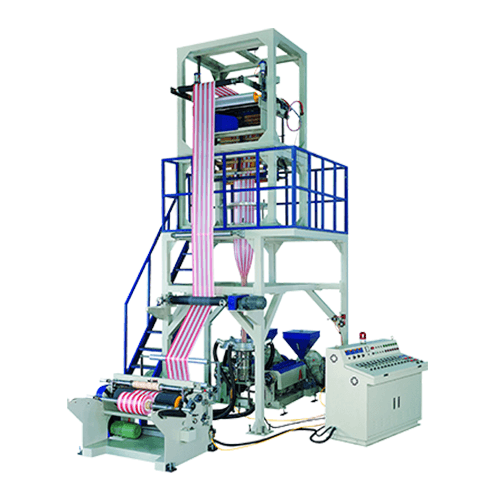

HDPE High Speed Mono Layer Blown Film Machine

產品分類 : 吹膜押出機

Application: T-shirt bags, shopping bags, garbage bags, mattress cover, laundry bags etc. Suitable material: HDPE / MDPE / HDPE+LLDPE Film layer: 1 layer Screw L/D ratio: 30:1 Direct-connection design gearbox. PID+SCR temperature controller. ABB or HITACHI inverter. Gusset device.

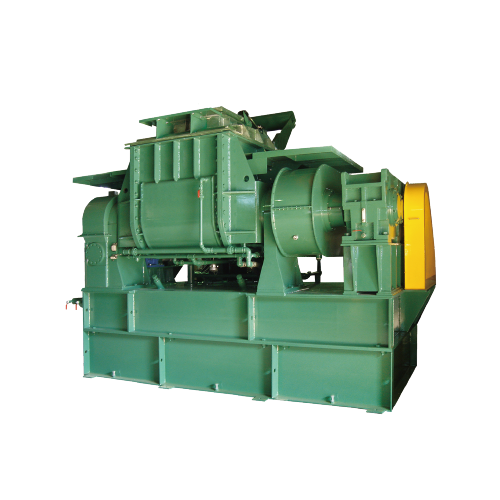

非加壓型捏合機 (DAK-系列)

產品分類 : 捏合機

此機器有「多種不同形狀的攪拌軸葉片設計」以及「排料方式」,廣泛應用於各種產業上的中、高黏度之原物料混練攪拌,如黏著劑、熱熔膠、矽膠、BMC、陶瓷、玻璃纖維、磁性複合物、印刷油墨、膠帶、熱固性樹脂、食品、化妝品、製藥工業等等。

HX系列30-200噸

產品分類 : 工業機器人