MICRO MOLDING

產品分類 : 射出模具

Micro molding is a very specialized art form, which is a kind of tooling design , manufactures small and precision plastic components with polymer-based functional devices, by increasingly demanded in the fields of life science, electronics, medical, photonics, automotive, and aerospace. The tiny-scale molding form of injection molding that entails building a cavity to match the shape of the part you want to make, sort of like the plastic molding that makes Lego bricks. THERE ARE THREE DIFFERENT THINGS TO KEEP IN MIND WITH MICRO MOLDING : Micro means the size of the part. It is the most common definition when dealing with micro molding. Micro features relates to tiny parts on a larger part. As a whole, the part can be big, but its components can be smaller, or micro features. Micro tolerance is how the parts are measured and how close to the needed measurement the part has to be to be considered a good or usable part. When a part is molded, it has to measure within the needed measurement (the tolerance), which could be as small as a thousandth of an inch. Small parts that are simple to make have tolerances that are not as tight and would be considered regular molding. SOME ADVANTAGES OF DESIGN GUIDE IN YOMURA AS : Dimension Aspect ratios around 6:1 (material dependent) Wall thickness : 0.3 mm ( 0.012”) min. for plastic Hole dimension : 0.2mm ( 0.008”) – 0.5mm ( 0.02”) min. Pitch of hole : 0.3 mm ( 0.012”) – 0.50 mm ( 0.02”) min. Tolerance (min) : 0.01 mm ( 0.0004”) – 0.02 mm ( 0.0008”).

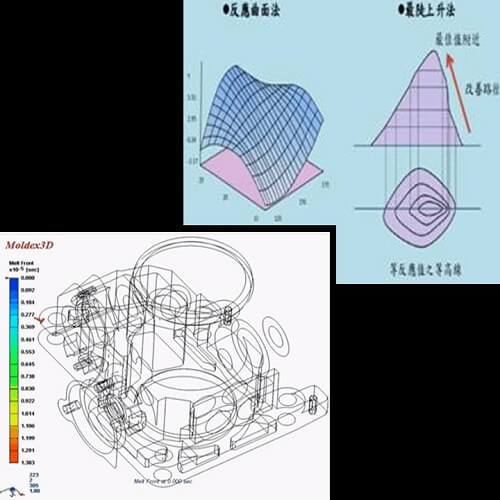

PROCESS OPTIMIZATION

產品分類 : 射出模具

In-Mold Decoration (IMD) is an efficient, durable and cost effective technique for printing, painting, and forming plastic decorations. However, a large number of parameters involved IMD manufacturing processes and the complex relationship between these parameters make the determination of the optimal parameter setting a challenging task. This paper proposes a systematic framework integrating Response Surface Methodology (RSM) and logistic regression to improve the yield of IMD manufacturing process. The integrated framework becomes easy to identify the optimal parameter setting,saving a great deal of time and money in the manufacturing process. On the empirical study in collaboration with Yomura, the proposed framework shows the significant result from 10% to 87.5% validating the viability of the proposed framework in real setting. (Key words: IMD, In-Mold Decoration, Parameter Optimization, RSM, Response Surface Methodology, Logistic Regression) EXPERT ANALYTICAL SYSTEM Yomura Technologies employs state-of-the-art technologies to select materials, validate component designs, develop tool designs and optimize its processes, ensuring that innovative concepts are achievable at the lowest cost of production. (Keywords: Moldex3D, Moldflow, PowerMill Pro, CAD system)

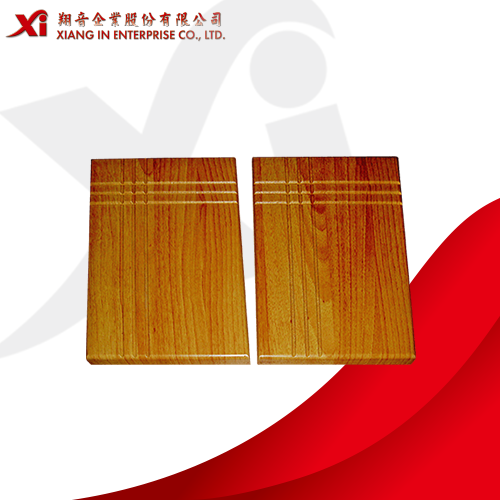

木材材質專用熱轉印膜

產品分類 : 薄膜

各類塑膠製品、布丁桶、容器、金屬外殼、家用品、文具用品、禮品…等多項商品。 透過翔音高品質的熱轉印膜與熱轉印技術,最適合將精美的圖樣印製在木質材料上。熱轉印具有直接印刷無法達成的多項功能,利用熱轉印膜與熱轉印機將精美圖案轉到產品上,適用各種材質,可提升產品的附加價值,降低成本,增加利潤。

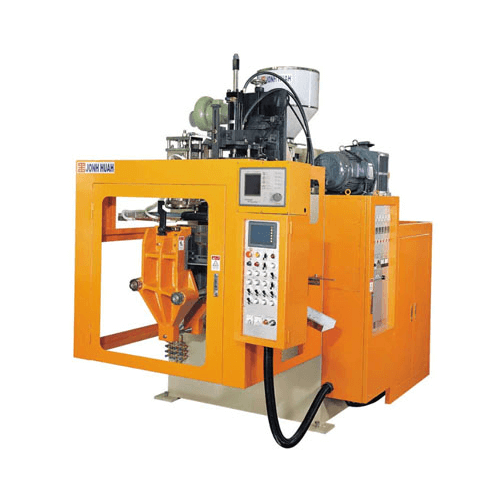

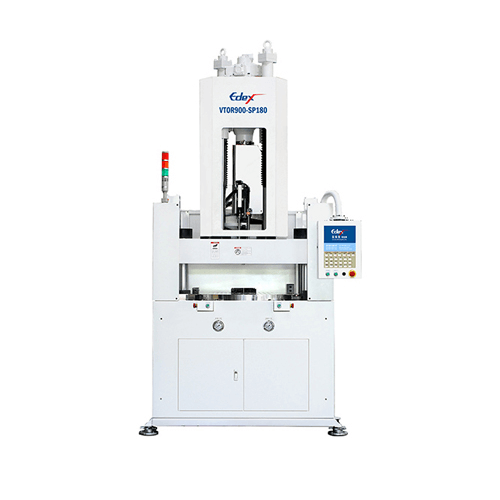

VTOR 系列 精密立式轉盤射出機

產品分類 : 全自動射出機

● 創新設計轉盤面積最小,容模尺寸最大 ● 可搭配柱塞式或螺杆式射出 ● 專利設計輔助進料系統,貯料跟臥式機一樣精准 ● 兩板直壓式四缸鎖模機構 ● 專利輻射式力學範本耐用30年 ● 安全光柵保護裝置 ● 智慧程式控制系統讓射出更容易 ● 相對同規格機型,機台高度低 ● 符合人體工學的工作臺高度 ● 電腦控溫氣冷式油冷卻系統 ● 精密節能油電伺服系統

塑膠管材押出設備

產品分類 : 管材及異型材押出生產線

全電式射出成型機齒輪箱

產品分類 : 齒輪箱

三隆精心研製之射出成型機齒輪箱有效驅動射出機射膠螺桿。搭配平行入、出力軸之齒輪箱,依據客戶個別需求,設計適合傳動高扭矩力之齒輪箱,使齒輪箱具備極優異之低噪音、低振動特性。

壓空成型+外型裁切+自動計數堆疊 SL-1220A + SL-520

產品分類 : 真空成型機

Flexible package solutions for various budgets and production needs. Fine processing competence fit for all standard and few specific plastics. Cold forming under high pressure load for high capacity and low cost. A cut of labor and waste via direct retrieval of plastic waste Low power consumption due to 30% saving energy and 40% compressed air cutting. A central control unit for easy operation and handy maintenance. • Rich experiences in package equipment with a tailor-made solution for you

HDPE 單層系列吹膜生產線

產品分類 : 吹膜押出機

King-Plus HES Series is designed to produce HDPE plastic film, while LES series for LDPE plastic film. These machines could give you advantages with high-quality, extraordinary mixing performance and high output capacity. With precise machinery design, they could work in efficiency state to realize the achievement of saving energy. HDPE & LDPE film is commonly used to shopping bag, garbage bag, surface protection film and barrier film etc.. There are some auxiliary options as like rotary die seat, auto loader, gusset device, embossing device and auto roll change device and so on, to build a especially-suitable blown film machine for you.