吹瓶樣品專用熱轉印膜

產品分類 : 薄膜

各類塑膠製品、布丁桶、容器、金屬外殼、家用品、文具用品、禮品…等多項商品。 具有直接印刷無法達成的多項功能,利用轉印膜與轉印機將精美圖案轉到產品上,適用各種材質,可提升產品的附加價值,降低成本,增加利潤。

PS、PC材質專用熱轉印膜

產品分類 : 薄膜

各類塑膠製品、布丁桶、容器、金屬外殼、家用品、文具用品、禮品…等多項商品。 各種PC和PS製成的塑料製品,都可以使用熱轉印,只要表面光滑平整,並使用特殊膠水,可以使圖案和產品完美結合。 熱轉印膜具有許多直接印刷不具備的功能,使用熱轉印膜和熱轉印機將優雅的設計轉移到產品上,使產品成為高價值的商品。 它可以提高質量,降低成本,增加利潤。

立式塑膠、立式射出成形系列 YHL 系列

產品分類 : 立式射出成型機

- 立式直立鎖模,直立射出的機體方式,結構簡單,寬檯面。 - 採射出中心偏位元的設計方式,使三面空間更加開放,能適用長條狀汽車密封條接角成型或帶有導線產品成型,讓成型作業更加容易。 - 立式塑膠射出機,射出系統採標準、模組化設計,通用各類型的嵌件注塑成型,塑膠成型能力特優。 - 立式橡膠射出機,射出系統採螺杆進料,柱塞射出二階段的設計,能適應不同硬度的橡膠材料,橡膠注射穩定精確。 - 最優化的設計方案,如鎖模/注射/塑化等單元最可靠的射出成型設備之一。

專業IMD模內裝飾整廠輸出

產品分類 : 注塑模內貼標射出成型機

• Total Solution For In Mold Decoration Technology. • Environment-friendly plastic decoration process - IMD/FIM/IML. (In-Mold Decoration / Film Insert Molding / In-Mold Labeling) • Product: Housing/casing of mobile phone, mp3/mp4, GPS, Lab-Tab Computer, 3D Labeling of Electric Goods;Automotive Dashboard Meters, Controllers, and Interior Decorative Items; the fancy colored Plastic Body Parts of Motorbike,...etc.

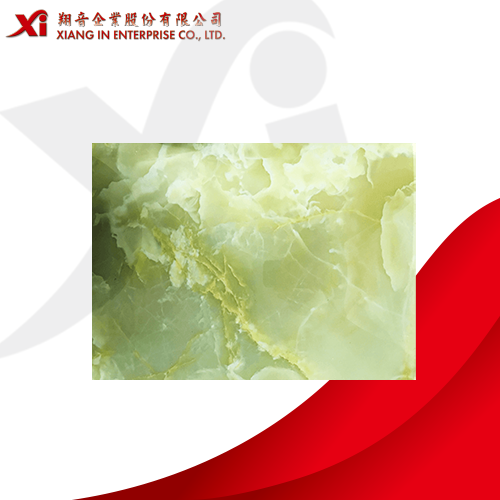

玻璃材質專用熱轉印膜

產品分類 : 薄膜

各類塑膠製品、布丁桶、容器、金屬外殼、家用品、文具用品、禮品…等多項商品。 玻璃材質也是絕對適合使用熱轉印技術的,只要先經過適當的表面處理,就能讓玻璃材質使用熱轉印技術產出精美的成品。熱轉印具有直接印刷無法達成的多項功能,利用熱轉印膜與熱轉印機將精美圖案轉到產品上,適用各種材質,可提升產品的附加價值,降低成本,增加利潤。

DOUBLE INJECTION MOLDING

產品分類 : 射出模具

Double Injection, sometimes known as 2 material 2 shot molding or 2K molding, is an innovative manufacturing process used to produce complicated molded parts from two different materials. Through a highly specialized and automated process we carefully control the injection of multiple materials, including two different kinds of resin, into a single, multi-chambered mold. Double Injection in performed on one machine that is programmed to perform two injections in one cycle. In the first cycle, a nozzle injects plastic into a mold. The mold is then automatically rotated and a different type of plastic is injected into the mold from a second nozzle. Double Injection Molding optimizes co-polymerization of hard and soft materials to create powerful molecular bond. The result is a single part with production and feature advantages. It can be used for a variety of product designs across all industries. It also allows for molding using clear plastics, colored graphics and stylish finishes which improves your product functionality and marketplace value.