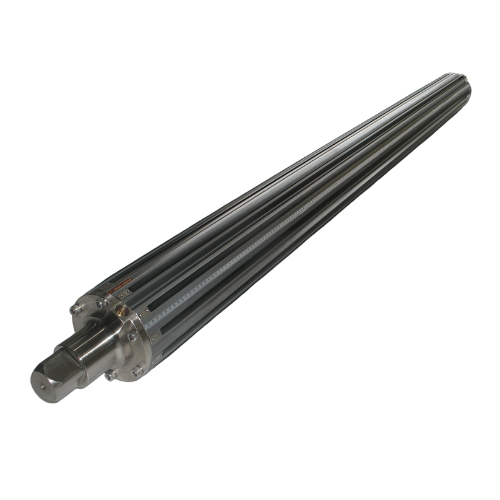

膠條(鋁條)式氣壓軸12mm~600mm

本型式之產品氣囊為TPU材質強韌耐用,採多爪設計置放於T型溝中,外部壓條可搭配橡膠、鋁條等材料亦可裝置滑動滾珠、滾輪等。 有高荷重型也有輕量化設計,6"氣壓軸管2米長約為20KG,最小直徑為12mm。

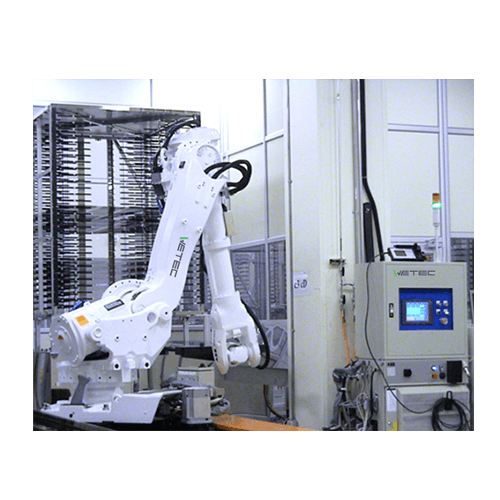

TFT-LCD基板移載系統整合

產品分類 : 工業機器人

· 玻璃基板移載系統 · 真空鍍膜Loading Unloading · CF Packing Unpacking · CELL段自動化移載 · 模組段製程自動化 · CF檢測移載自動化 · CIM軟體整合

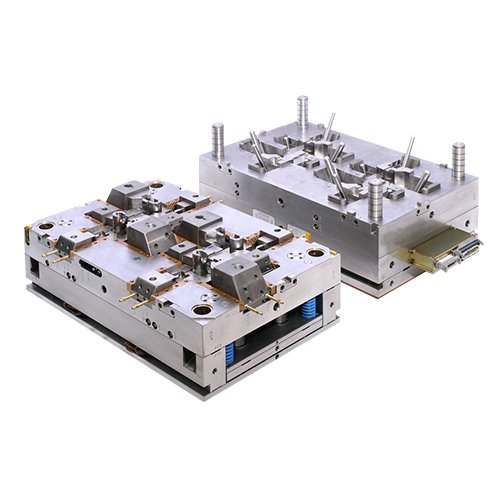

LIQUID INJECTION MOLDING

產品分類 : 矽膠射出成型機

Liquid Injection Molding (LIM) and Transfer Molding are preferred processes for manufacturing solid silicone rubber items used in a wide range of applications such as medical equipment, watersports, gas masks, military gear, waterproof device cases, 3C products and much more. MATERIALS: Shin Etsu / Dow Corning/ GE Silicones ADVANTAGES & APPLICATIONS: Low viscosity and lower injection pressure, good for silicon molding Good chemical stability and environmental protection High dimensional accuracy It produces high quality parts without secondary finishing and allows much shorter production cycles than other processes. Over-molding together with hard plastic frame (PC or ABS etc.) for waterproof devices, shock proofing, shielding, etc. Very thin wall design (0.25mm thick around) for silicone to adhere on plastic housing (rib) to meet the demand of low profile product design. Water proof feature can be secured by the combination of soft rubber contacts and with constant pressure provided by hard plastic housing (rib).

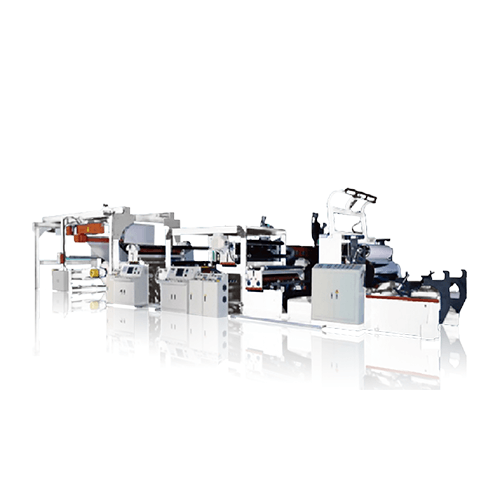

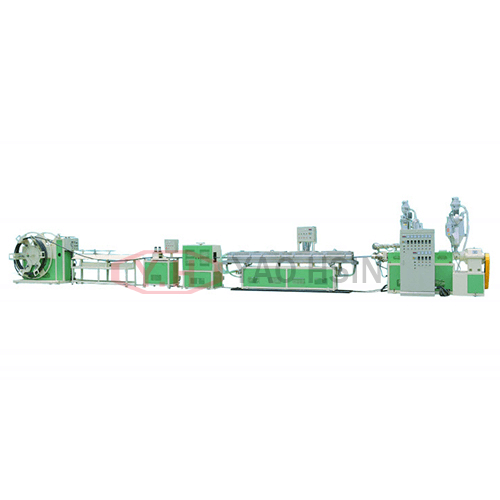

三合一模頭切粒塑料回收造粒機

產品分類 : 製粒機

Single plant line reducing costs for labor and energy Special design of die head, not only producing evenly sized pellets but also reducing attrition rates of the cutting blades

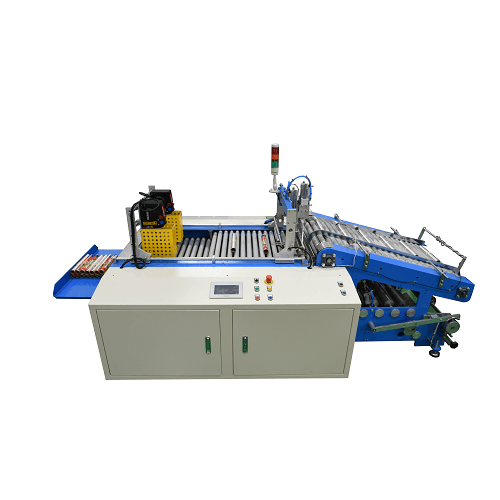

AUTOMATIC SHRINK FILM PACKAGING MACHINE (TPG 50)

產品分類 : 分切機和複捲機

Model TPG50, the automatic shrink film packaging machine. A special design for wrap roll products. It can be connected to the back side of rewinding machine as an automatic production line. You can not only make your product refined and protected, but also arrange manpower more effectively. TPG50 is carried 3 conveyors as 3 work areas. It uses conveyors to deliver products to the processing area. You can choose automatic feeding of the material,or feed by detected sensor. As shrinkable films, BOPP, PVC and PE can be used on TPG50. The length of over wrapping film can be set manually or detected by the mark sensor. For packing decoration, you can use printed film; or, equip with a label paper device. The device will insert a piece of label before shrinking. The label will be wrapped inside the film, makes your product eye-catching. The last step, electrostatic device and thermal-wind will perfectly pack your products! Welcome to consult machine with us, we will at your service.

連續式中空成型機 PK-TL 系列

產品分類 : 押出中空成型機

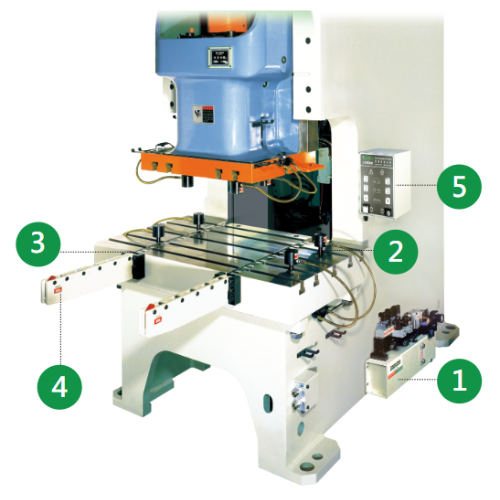

高精密偏光板切片機 TRC-1200

產品分類 : 切割機

Stable Bottomdead Center Accuracy: The delicate-design mechanism can maintain the stable bottomdead center accuracy under high speed cutting running. Knife Height Adjustment Mechanism: When setting up knife mold, the instrument of the machine can make right and left adjustment respectively as well as complete the setup of knife mold clearly and rapidly. Easy-Operate Operation Panel: This machine adopts new touch screen featuring affinity operation interface that makes an easy operation, thus lowering cost for employee training. Accuracy Delivery Mechanism: Oaded with new mechanism, the delivery move volume digital setup, it achieves a stable an accurate delivery function. High Speed Cutting: The strengthened-design mechanism can allow high speed cutting. High Torsiodamper: With the strong rigidity of the unit, noise can be maintained within the standard value under high speed running.

電動射出機專用齒輪減速機

產品分類 : 齒輪箱

(1) 採用特殊之設計與製造方式,適合用於高扭矩、高轉速之運轉環境中。且運轉時損耗少低噪音,能提供齒輪減速機較高之傳動效率。 (2) 於輸入軸(電動馬達)與輸出軸(連接驅動螺桿和料管)之間,採用三段減速設計。其輸入軸與輸出軸兩者之間的距離空間,恰好正足以涵括馬達、減速機箱體及連接螺桿和料管之完整系統配置嵌入其中。形成一U型外觀設計,占用最小的空間,達到最大的空間使用效益。 (3) 齒輪元件之設計製作,採用AGMA標準(亦接受客戶指定之DIN、JIS標準設計製作),齒輪元件材料採用高品質之低碳合金鋼(一般為SCM420等級之材質)製作。齒輪元件經滲碳熱處理之後,再經由齒面研磨製程加工後,其精度等級可達AGMA10級以上,確保齒輪減速機運轉時之低噪音、低損耗和高效率之特性。 (4) 馬達法蘭和驅動軸之設計製作,除本型錄上之標準形式可供選擇之外。亦可依據客戶的需求,客製化設計製作,以達到TGSM齒輪減速機最廣泛的適用性。

PET吹瓶機-廣口系列

產品分類 : 臥式中空成型機

採用64K彩色觸摸屏控制系統,PLC操作友好。獨特設計的機器結構使將吹塑機與輸送機系統結合起來非常方便。瓶胚自動排列,以便以單一方式供料,分料架由伺服電機驅動;這樣可以避免瓶坯卡住,機器掉落或瓶坯浪費。採用伺服控制螺桿驅動系統;它是快速,穩定,清潔和環保的。將預成型坯以矩陣模式送入加熱系統,並通過單燈和雙面加熱均勻加熱。採用帶有雙面加熱設計的單燈,與競爭對手的方法相比,將節省約50%的熱量消耗。具有溫度反饋功能,通過調節紅外燈自動控制加熱爐中的溫度,以減少預結晶的問題。特殊設計的加熱箱可提高更換紅外燈和冷卻坡道的維護便利性。夾緊機構由伺服電機和凸輪驅動。這樣可以實現準確而穩定的運動,低噪音和最小的污染。利用空氣回收系統,效率高達50%,因此不需要低壓空氣壓縮機。這將節省設備投資成本和能源消耗多達15%。

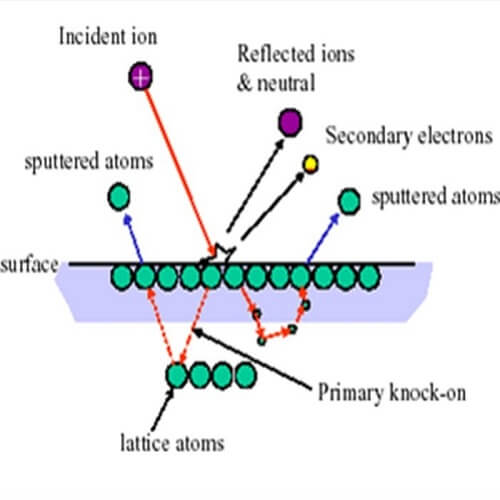

EMI SHIELDING

Protect parts from electromagnetic interference. It is used to protect electrical signals from the outside world. Currently, construction methods for anti-EMI are electric plating, sputtering, spraying, electric paint, or the direct use of the shielding effect of metal materials, such as the use of stainless steel, aluminum, iron or aluminum-magnesium alloy, and other materials. The metal piece of masking is low cost and meets current environmental regulations. But the processing and assembly are complex and miscellaneous and are poor stability. Water electroplating, electric plating, conductive paint, and other environmental laws and regulations conflict or doubt, the establishment of the new plating plant is not easy in the future and will gradually be phased out and replaced. So far, workers using a vacuum sputtering process and the magnesium alloy should be the main way to effectively combat EMI.

捲取機

產品分類 : 分切機和複捲機

捲取機安裝在壓延機生產線上或各種材料的交換或復捲生產線的最終端,因應各種不同製品的捲取要求,我們的捲取機設備配有精密的調整裝置及簡易的操作,速度可以逹到200米/分,捲軸直徑最大可達1500mm,寬度最大可達6000mm。某些機型可以將薄膜的上部捲到捲軸的里面或外面,最後經過多次中間分切,可同一軸上捲取最多3個捲軸。薄膜的切割採用鍘刀式或剪刀式設計,通過驅動電機及控制系統,可以保証在高速狀態下片材捲取的最高張力精度。 捲取機的類型多樣,可依不同製品配置或定製。其中包括;自動中心捲取機(貼膠帶或免貼膠帶式)、自動單輪式表面捲取機、多輪式表面捲取機;適用子不同薄膜的專用導開機、復捲機和捲取機;輔助設備(修邊刀和中央切割裝置,缷捲和稱量機組,軸自動抽出裝置)等。

筆類樣品專用熱轉印膜

產品分類 : 薄膜

各類塑膠製品、布丁桶、容器、金屬外殼、家用品、文具用品、禮品…等多項商品。 具有直接印刷無法達成的多項功能,利用轉印膜與轉印機將精美圖案轉到產品上,適用各種材質,可提升產品的附加價值,降低成本,增加利潤。

PVC,PE,ABS管材製造機

產品分類 : 管材及異型材押出生產線

五層共擠吹膜機

產品分類 : 共擠吹膜機

Nowadays, flexible packaging replaces the containers that need lots of energy to manufacture as like timber, paper boxes, glass and steel. Because flexible packaging has lower temperature required in processing than above materials, the emission of carbon dioxide can be reduced extremely. It is no doubt that development of flexible packaging becomes the new market trend currently. The usage of flexible packaging is covered in consumer and industrial goods, food, medical treatment and electronic products and it could be as prevention film, protection film, shrink film and so on. The flexible packaging industry emphasizes to how to downgauge the film structure and possess multiple different performances simultaneously. The multi-layer machines could be possible to achieve the expected outcome. The multiple materials in multi-layer machine could give different performances in each layer. Also, it could be more flexible to arrange the distribution of material that let users could manipulate the resins more extensive to reduce the cost in material and production. In current time, at the issue of sustainability, people pay attention to the possibility in recycling to reuse and biodegradable material development. In the flexible packaging industry, it is an opportunity and a challenge for each manufacturer to realize high-performance film, at the same time, to save energy and to be friendly to environment . Please feel free to contact us and tell us the information about the film, King-Plus will provide a tailor-made blown film machine to your requirement.

SP-420 / 60205

Especially for bulky plastic products. Eliminate the disadvantages of traditional high horse power crusher.Also for cracking unusual objects,waste tyres,logs,sleepers,etc. ● 2-shaft,claw-cutter breaker has the best ability to shred anything with low noise,vibration free. ● Auto reversible equipment to prolong the life of machine.