密閉式混合機(萬馬力)

產品分類 : 橡膠混合機

橡膠、塑膠及化學工業原料混合加工用 特色: 1. 攪拌軸: 以特殊合金鋼鑄造,設計為二翼式,翼尖熔接耐模耗材料及全部表面鍍硬質鉻及拋光處理,翼根設計有冷熱媒傳導迴路,熱傳導效果良好。 2. 混合室: 以中碳鋼板焊接組合加工製成,混料接觸面均經鍍硬質鉻及拋光處理,中間槽為鑽孔式迴路,具有優良之熱傳導。 3. 卸料門: 設計為落門式,結構堅固,防漏效果良好。 4. 加壓錘: 以垂直空壓缸操作,達到壓料在混合室內良好混練效果。

密封式高速混合機

產品分類 : 橡膠混合機

This Intensive Mixer is designed for mixing compounds and specific plastic. The structure of the machine consists of the main air cylinder, floating weight, feeding door, mixing chamber, rotors and discharge device. When performing mixing compound operations, the material and ingredients are fed together into the mixing chamber. The material in the mixing chamber is repeatedly sheared and squeezed by the rotors. This provides a series of chemical rotations between the material and the ingredients, which enables the material pieces to stick together into a paste mass shape. Mixing compound operations are performed according to the set temperature and conditions. This specially designed mixing machine provides efficient mixing and refining for a wide range of raw materials, such as raw rubber, resins, asphalt, cellulose, PVC ane EVA…etc.

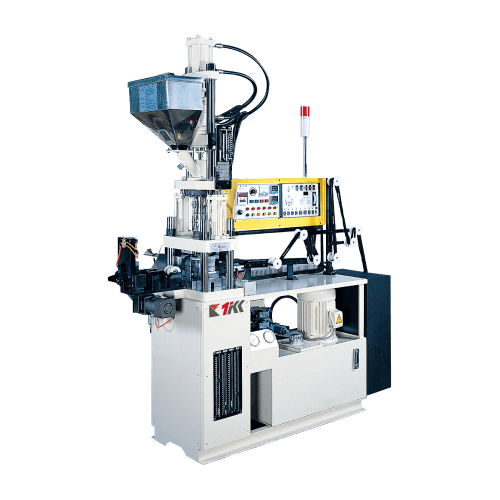

射拉吹中空成型機 MIB-SERIES

產品分類 : 射出中空成型機

該機型可經濟地使用多種材質(如 PET、PP、PC、TRITAN、PES 等)製造高品質容器,同時具備節能特性。快速的成型週期可協助客戶提高生產效率並獲得最大利潤。 三站旋轉式加工流程 此機型採用旋轉圓盤結構,依序完成三個加工站流程: 第一站為注射成型,機台具備高夾模力,可確保瓶胚品質穩定。 第二站進行預胚加熱,搭配精密溫控系統,幫助客戶獲得最佳成品瓶品質。 第三站執行伸拉與高壓吹塑成型,塑造瓶體外型。 完成後可輕鬆取出成型完成的高品質瓶身。