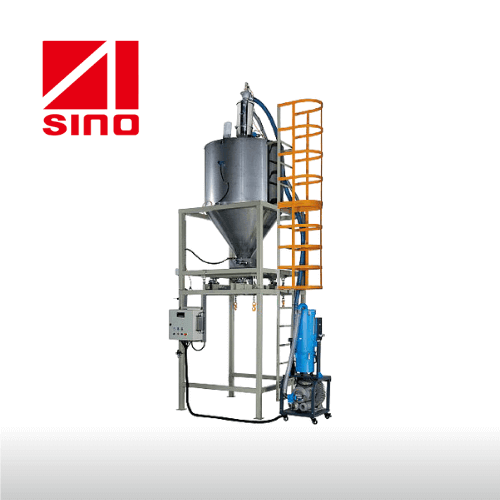

粉體劑量自動輸送整廠規劃設計

產品分類 : 配料設備

自動計量設備提供有效率的混合及材料處理 裝配自動輸送系統、計量系統、攪拌桶、捏合機、押出機與鋼結構設備 計量供料器:計量式螺旋供料機 混合物料自動輸送 電腦現場連線操作 完整現場服務

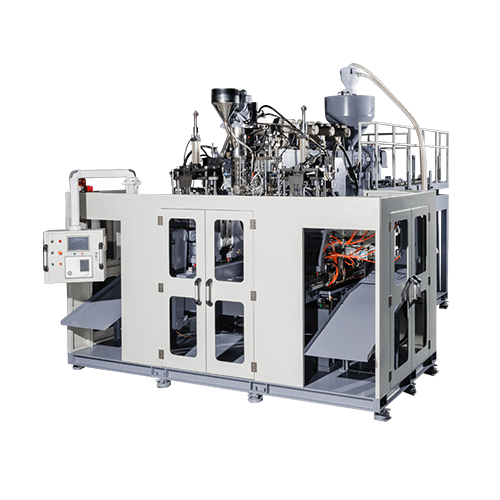

歐化料斗乾燥機SHD-U

產品分類 : 乾燥機除濕機

SHD-U可用於大多數不易吸濕的塑膠原料進行高效乾燥作業,以保證最終成型製品的品質。其結構簡潔,可方便放置於成型機入料口處,也可選用腳架實現落地式安裝,以滿足快捷移動的需求。當廠房高度不足時,落地式安裝也是一種更好的選擇。另有諸多配件供選用,以滿足不同特定生產需求,如熱風回收、磁力架、護梯護欄等。

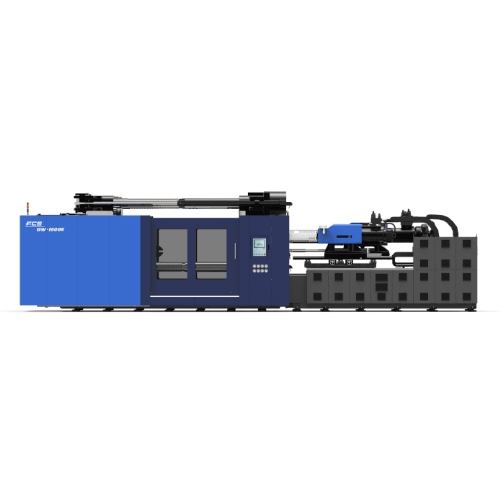

二板式多組分射出機 (GW-R系列)

產品分類 : 壓板射出機

為 FCS 全新發表之超大型二板式多組分射出機,廣為汽車業、大型家電外殼,家具業等雙色及多色製品所採用,尤其適合一體式燈罩、貫穿式車尾燈罩、車窗及汽車塑化鈑件等產品。鎖模力涵蓋 1,000~3,300 噸。

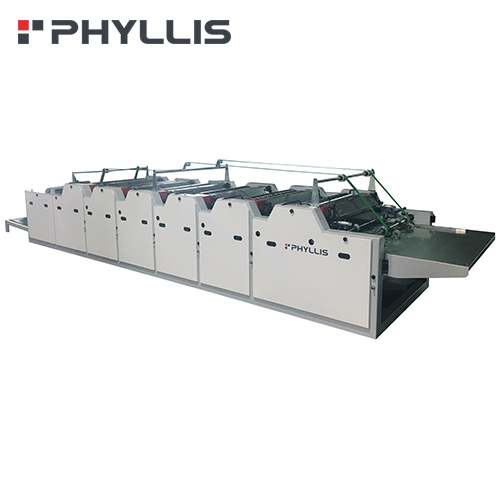

單層押出聯結式淋膜複合機 (WEL-DT系列)

產品分類 : 押出塗佈機

我們以最嚴謹的態度製造設備,就正如我們對模頭品質的堅持,瑋禮以多年在軟性包裝的專業的經驗嚴選出最高品質的模頭,並以我們的專業與日本第一模頭製造商共同研發出最適合軟性包裝應用的淋膜複合模頭。獨家特殊的內擋片無耳料設計有效的達到節省廢料的目的,並且適合於高速生產無須顧慮斷料問題。所有的模頭都是採用最頂級的鋼材並經由多道加工及特殊處理的製程,所以不管是在穩定性、厚薄精度的控制都有高水準的表現。

模具控溫機 (YBMI/YBMD)

產品分類 : 控制設備

塑料有熱脹冷縮的物理性質,因此若溫度不穩定或控制不當,會產生成品夾水紋、縮水、扭曲、變形及表面光澤不良等現象。而使用晏邦模具控溫機即可解決此類問題,能促使模具保持適當的溫度,可大幅減少試模次數及降低成型品之不良率,確保產品品質。 P.I.D.智慧型自動演算的溫度控制器,能準確顯示和控制模具溫度於所需要的溫度±1°C 內。兩段式加熱結構設計,可視所需之溫度增減電力,並配合特殊的發熱構造,可省時省電。專利斷熱式分離設計,延長機台壽命與保障工作安全,維修與保養工作更有效率和安全。 YBMI :油式,適合長時間運轉,恆溫效果好,適用於小且薄的產品不會有毛邊。油的熱傳遞係數較小,若熱煤油使用不當,嚴重時會燒壞加熱器,需定期更換熱煤油。溫控在150 °C以上,建議選用油式。 YBMD :水式,水的熱傳遞快、冷卻效果佳、不會污染模具。但水的沸點低,依據水的成份可能會結垢或腐蝕,引起壓力損失過大和模具與流體之間的熱交換效率下降等問題。溫控在 150°C以下,建議選用水式。

工業控制器 - AR系列

產品分類 : 工業軟體

集合先進精確及簡易實用兼備的分散式處理系統,能以高速網路聯繫人性化編輯程式和遠端控制模組,其擴充性佳,且使用32位元CPU(528, 72MHz)作主程式運算,並自行開發物件導向編輯程式,PLC程式採用階梯式(Ladder)編寫流程,簡易流暢。 此開發可廣泛適用於射出/押出/押鑄機械,展現未來一站式控制優勢。 長新

高壓壓力變送器

產品分類 : 指示器

ll Scale Pressure Range 0-100 thru 0-100K PSIS (0-6.89 thru 0-6894 bar) Accuracy (RSS) (BFSL Non-Linearity, Hysteresis, Non-Repeatability) 0-300 PSI thru 0-15K PSI Ranges±0.20% FSO ( ±0.15% FSO improved with "DN" option) < 0-300 PSI or > 0-15K PSI Ranges±0.25% FSO ( ±0.15% FSO improved with "DN" option) Linearity (Best Fit Straight Line) 0-300 PSI thru 0-15K PSI Ranges±0.10% FSO (BFSL), Typical < 0-300 PSI or > 0-15K PSI Ranges±0.15% FSO (BFSL), Typical Hysteresis < ± 0.05% FSO, Typical Repeatability < ± 0.05% FSO, Typical Full Scale Output (FSO) 16 mA Zero and Span Balance ±1% FSO Long Term Stability ≤±0.25% FSO per 6 months Response Time <2 mSec to reach 90% FSO Temperature Effect on Zero ≤±1% FSO per 100°F (37°C) Temperature Effect on Span ≤±1% FSO per 100°F (37°C) Compensated Temperature 70°F to 170°F (21°C to 76°C) Operating Temperature -40°F to 190°F (-40°C to 87°C) Storage Temperature Limit -65°F to 250°F (-53°C to 121°C)

針閥式熱嘴-AVMT

產品分類 : 熱澆道系統

本熱嘴適合用於大型或是形狀複雜之塑件。 本熱嘴於流道之中有一閥針以氣壓或油壓驅動進行澆口之開關動作,當閥針有打開時,可以行塑料充填,於塑料充填完成,保壓之後,再以閥針封住澆口,如此則可使用於大澆口的情況,並可免除澆口處牽絲的問題,使保壓的過程趨於完美,同時可獲得美觀的澆口。 對於一模多進澆之模具,可採用序列控制方式來解決結合線等問題。

清潔水垢用酸劑 & 強力去油污鹼劑

DD除垢劑 專為淨化、預防水垢而使用,超濃縮的專利配方,可分解頑固水垢,能夠不停機操作的特性,既減少停機損失,又節省能源消耗。而 GC-S 則專治頑強的工業油汙,有良好的操作安全性與泛用性,可應用在各種材質上

DESIGN AND DEVELOPMENT PARTNER

產品分類 : 射出模具

JDM / ODM SERVICES When bringing a new product to market or re-launching an existing product with new features, key success metrics are quality and timing t o market. Either or both may be negatively impacted if the design proves difficult to manufacture especially if there is a rapid demand for increased volume. A design partner who is well integrated with a full service manufacturing system knows how to minimize risk. Our design teams have executed numerous design-build projects for customers across a variety of industries on a global scale. We incorporate manufacturability, assembly and test principles into the EDI-early design stages involved of a product to assure seamless production. JDM/ODM services include : To use the PLM system to monitor the product life cycle management. Concept Development Mechanical Drawing Layout Documentation Verification Material Management & Sourcing Rapid Prototyping & Soft Tooling Initial Pilot Builds & DFM αTest /βTest/ Burn-in Tooling & molding in house Final Assembly Following the design phase of your product, we build prototypes to test the DFM manufacturablity and any industry compliances. Prototyping may occur multiple times at various points in the design and planning stages for a project. Once all the design and manufacturing issues are worked out, we can rapidly transition into full-scale production. Please visit our Contract Assembly page to learn more about our assembly facilities. OEM Our Original Equipment Manufacturer (OEM) service is responsible for designing and building a product according to a customer’s own specifications. Our service also includes & DFM,EDI,3D printer rapid prototype global distribution and returned product factory repair, which can greatly reduce customer’s overall production costs.

無柱立式關模臥式射出機-YC 系列

產品分類 : 立式射出成型機

Vertical clamping, without machine column design, the mechanical constitutive property is strong, Injection powerfully, suit large-scale embedment to take shape the processing.

磁化機-工業水垢消除與預防

水流經過磁場處理,可改變水內的水分子與礦物質之分子結合方式改變,從而避免水垢於管路結成硬塊,而是形成粉末狀便於在過濾系統回收。此外,水分子的結合暫時改變,也降低了水的內阻,使得磁化後的水可以大大的被應用在各類工業領域(冷熱水交換)、商用、家用,甚至農業灌溉領域。

MICRO MOLDING

產品分類 : 射出模具

Micro molding is a very specialized art form, which is a kind of tooling design , manufactures small and precision plastic components with polymer-based functional devices, by increasingly demanded in the fields of life science, electronics, medical, photonics, automotive, and aerospace. The tiny-scale molding form of injection molding that entails building a cavity to match the shape of the part you want to make, sort of like the plastic molding that makes Lego bricks. THERE ARE THREE DIFFERENT THINGS TO KEEP IN MIND WITH MICRO MOLDING : Micro means the size of the part. It is the most common definition when dealing with micro molding. Micro features relates to tiny parts on a larger part. As a whole, the part can be big, but its components can be smaller, or micro features. Micro tolerance is how the parts are measured and how close to the needed measurement the part has to be to be considered a good or usable part. When a part is molded, it has to measure within the needed measurement (the tolerance), which could be as small as a thousandth of an inch. Small parts that are simple to make have tolerances that are not as tight and would be considered regular molding. SOME ADVANTAGES OF DESIGN GUIDE IN YOMURA AS : Dimension Aspect ratios around 6:1 (material dependent) Wall thickness : 0.3 mm ( 0.012”) min. for plastic Hole dimension : 0.2mm ( 0.008”) – 0.5mm ( 0.02”) min. Pitch of hole : 0.3 mm ( 0.012”) – 0.50 mm ( 0.02”) min. Tolerance (min) : 0.01 mm ( 0.0004”) – 0.02 mm ( 0.0008”).