近期更新 立即訂閱

CHEN WAY: 5 Minutes to Know HDPE Blow Molding

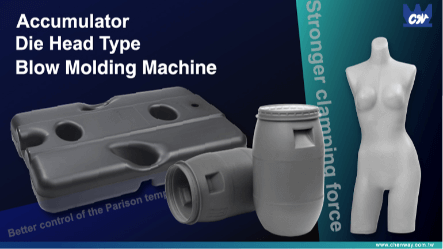

What is HDPE Blow Molding? HDPE Blow Molding is the process of molding a softened thermoplastic hollow form called a Parison. This Parison is first vertically extruded from the Die Head of a Blow Molding Machine and then, it is inflated against the cooled surface of a closed mold, the expanded plastic then solidifies into a hollow HDPE product that needs none or very little finishing processes after the Blow Molding.

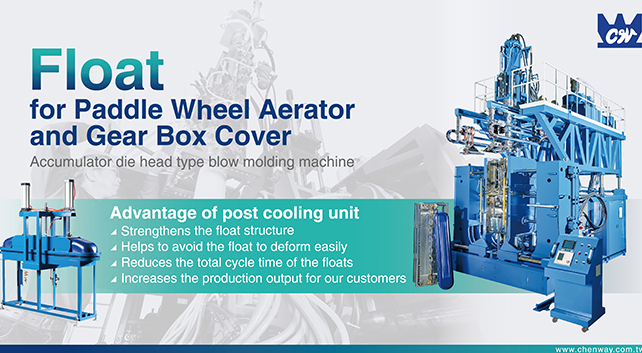

Advantages of using Extrusion Blow Molding Machines: Your Best Solution for Aquaculture Fish Farming Floats!

Blow Molding machines have many advantages when it comes to making hollow plastic products, and especially for large hollow plastic products they are really your best solution. As an example, one very popular and common application of Blow Moulding for large products is the molding of Paddle Wheel Aerator Floats and Gear Box Covers for Aquaculture; these floats are used in Fish Farming to hold the Paddle Aerators Wheels that give the fish the oxygen they need from the environment for respiration.