近期更新 立即訂閱

Plastic Recycling Continues to Grow Worldwide

The packaging film sector (stretch film, CPP film and etc.) and plastic bag producers are required to use a much higher percentage of recycled pellets in the end products. For better quality control and to maximize the reusability back into the film extrusion lines, more producers have decided to recycle all the production waste internally instead of outsourcing it.

One-step Recycling for Raffia and Woven Producers

In general, 8% of production waste is generated during the process (from tape line production, looming and printing). The price of raw material is almost doubled comparing to the cost of having it recycled in-house. It would make sense for medium and large-sized Indian producers (who generate more than 30~40 tones of scraps per month or more) to recycle the production waste internally to reduce production cost.

Recycling Machine Sales Doubled for POLYSTAR in 2021

New regulations in many countries now require producers to use a higher percentage of recycled content in flexible and rigid packaging products. Instability of raw material prices and supplies also forces plastic producers to better recycle their own production waste. The growing demand for plastic recycling directly reflects the machine sales for POLYSTAR.

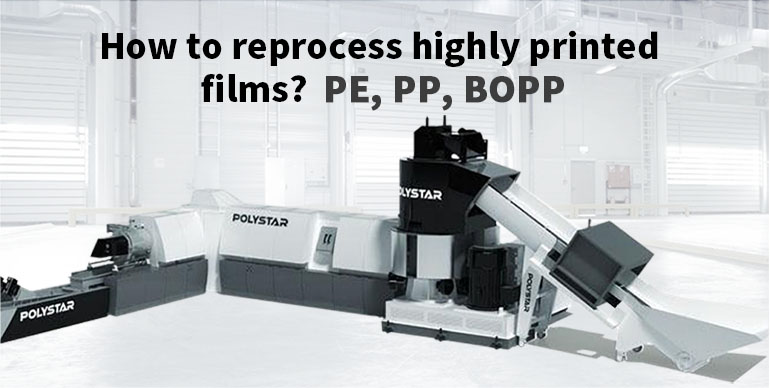

POLYSTAR - How to Reprocess Highly Printed Films? PE, PP, BOPP

The industry of plastic has been changing and evolving over the years that’s why plastic recycling has become a necessity among plastic producers. The laws toward plastic have become stricter, which require the producers to use a higher percentage of recycled material in their final products. The benefits of these laws are for lowering the production cost of the producers and reducing the plastic waste in our environment.

POLYSTAR - Air-pelletizer Increases Reusability % Back to Bag Production

The air-cooled pelletizing recycling machine Repro-Air has proven to be a big cost-saver for two of the largest bag producers located in Solo, Indonesia – Cahaya Kharisma and Djerapah Plastindo. According to the well-known HD and LDPE bag producers, the air-pelletizing technology is even better than water-cooled recycling machines for some applications.

Fast Delivery and Simple Installation of Recycling Machine - A Clear Advantage for Film and Bag Producers

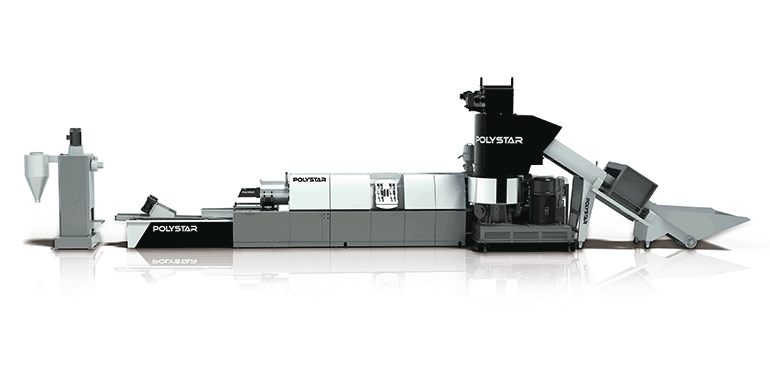

Multiple sets of recycling pelletizing extruders Repro-Flex have been installed in South Africa in the year of 2020, mainly for film producers and bag converters of LDPE, HDPE, PP and BOPP who process their post-industrial (factory) waste in-house.

Post-consumer Recycling. Double the Simplicty. Double the Efficiency

The need of a more automatic, self-cleaning filter to reduce labor cost and improve efficiency has been a key factor for professional post-consumer recyclers, for applications such as paper label removal and milk/shampoo bottles...

Taipei Pack 2020 - POLYSTAR Provides Simple Recycling Solutions for Flexible Packaging Film

POLYSTAR will demonstrate its latest developments on pelletizing technology during the upcoming exhibition Taipei Pack 2020, providing simple yet efficient recycling solutions for a wide range of industrial waste from the plastic packaging sector