押出機與押出整廠設備

熱門訊息

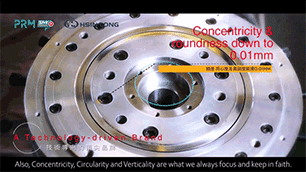

COMPREHENSIVE EXTRUSION SOLUTION AND CUSTOMERS RELIANCE-HSIN LONG

HSIN LONG, one of the leading manufacturers of Blown Film Die Head Industry, has been forging its outstanding reputation for over 50 years. HSIN LONG took advantage of the great potential they had by expanding their machinery with a complete Blown Film Die Head production line with layers up to 11 layers and diameter reach 1.5 meter...

POLYSTAR - How to Obtain Excellent Quality Plastic Films for Lamination?

Laminated film is an excellent application for packaging food like coffee, snacks, cookies, nuts (peanuts, pistachio, almonds), and others. It is ideal for packaging because laminated films have protection from humidity, oxygen, aromas, fats, and light. All these factors decompose or reduce the lifetime of the packaged product. For this reason, the protective barrier is the most important element in the laminated film, which is composed of PE (LDPE), BOPP, PET, and others.

PLASCO MONOFILAMENT LINE & STRAPPING BAND LINE & RAFFIA TAPE & TWINE EXTRUSION LINE

PLASCO is an Industry leader in design, manufacture, and supply of innovative plastic extrusion line to the market worldwide. Our performance spectrum range from individual extruder machine, to the engineering, planning, and delivery of complete turn-key factories. We offer our customer our specialty knowhow in the field of plastic extrusion, our innovations and engineering background is our core competence to provide customized solution and has driven us success for more than 30 years.

TWINSCREW - Applications of TwinScrew's Extruding System for Making Thermoplastic Starch (TPS) Granules and TPS-blended Bioplastics

The investment on reducing carbon emission is becoming the most critical factor determining the sustainable growth of the manufacturing industry. Carbon neutrality achieved by 2060 has been committed by the countries contributing more than 75% worldwide GDP.

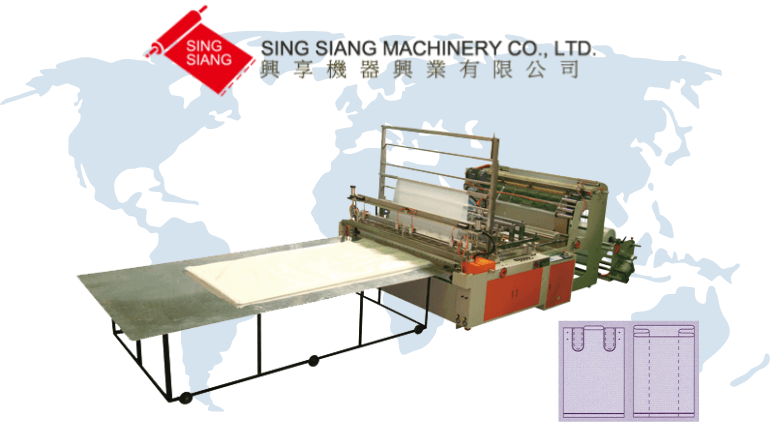

JANDI’S - The Differences in the Nature of PE & Biodegradable Material (PLA/PBAT Based)

According to the material supplier, bio-degradable material cannot be recycled easily. But, if not trying to recycle, the disposal of the waste & die-cut from bio-degradable material will become big additional expenses. Even if you may recycle the bio-degradable material, the time, space and workman ship required for the collection of the waste, will already create additional costs. Because of the above reasons, JANDI’S JIT is the best solution for the production of PLA/PBAT Bio-Degradable T-shirt bags.

KANG CHYAU: Reaching Outstanding and Efficient Solutions on a Changing Market

This past year, 2020, many players from the Plastic and Rubber Industry experienced distresses on two major points, such as how strong the pandemic was going to affect the economic situation and how long it was going to take for its stabilization. In the current year, we continued analysing thoroughly how the industry has been gradually healing and how Taiwanese Manufacturers have been innovating on performance and assistance to bring the best to their customers in these hard times.

PE Bag Production – Which Extruder is the Best Choice?

For PE bag production, single layer blown film machine has been the most common type of extruder to use. It is probably still the best machine for products such as fruit and vegetable bags (perforated bag-on-roll) that use mainly virgin materials with low film thickness ranging from 6 to 18 microns. Single layer machine is also the favorable choice for biodegradable bag production.

POLYSTAR - PE Bag Producers Step up in Quality and Efficiency in Vietnam

The Vietnamese plastic sector has grown significantly in the past 5 years thanks to many unique advantages that the country has. The ability to produce lower cost yet good quality plastic products is ideal for export markets such as the US, Japan, Europe, Australia and Cambodia. The local market demand is also increasing in sectors such as live seafood packaging, industrial and agricultural film, in a country of large population of nearly 100 million.