A Guide Selection for Plastic Printing Machine

Printing technology is crucial in the plastic and rubber industry for creating vibrant packaging. This article aims to introduce the most commonly used printing machines to global buyers, including rotogravure printing machines and flexographic printing machines. By providing descriptions, advantages, and features of these printing machines, you will understand how to select the printing equipment that suits your specific needs.

In the packaging industry, printing machines are an indispensable component. Prior to being transformed into strips and formed into bags, the films produced by the blown film machine undergo a printing process. This step is essential for achieving vibrant colors and showcasing beautiful, unique patterns on the packaging, enhancing its overall visual appeal.

Printing machines have versatile applications across a wide range of materials, such as paper, plastic films, textiles, ceramics, metals, glass, and more. When selecting the suitable printing technology and equipment, it is important to consider the specific characteristics of the material and the desired coloring requirements.

Here, PRM focuses on the discussion of the plastic and rubber industry. Therefore, this article specifically explores printing machines that are utilized to make plastic films.

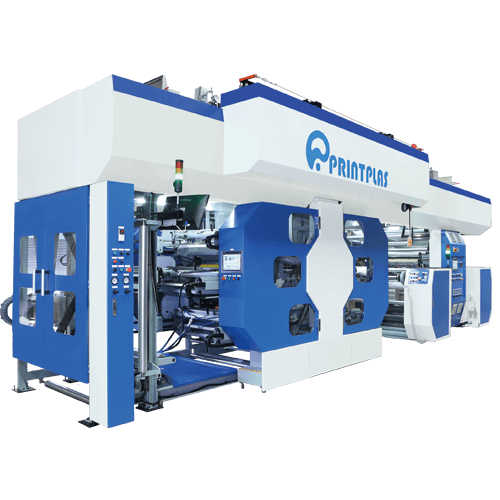

Flexographic Printing Machine: Flexographic printing machines are extensively used in the plastic and rubber industry. These machines utilize a flexible plate, known as a flexographic plate, for printing. The raised portions of the plate contain the images and text to be printed, and ink is transferred onto the printing material through these raised areas. Flexographic plates are typically made from elastic rubber or polymers and apply controlled pressure to achieve the transfer of ink.

Flexographic printing offers high-speed printing capability, strong adaptability, and suitability for various types of plastic and rubber materials. It allows for quick switching and adjustment of printing content while delivering high-quality images and text. It is suitable for printing on a wide range of materials, including paper, plastic, metal foils, textiles, especially for large-scale production of packaging materials, labels, and films.

PRM-TAIWAN recommends high-quality Flexographic Printing Machines for you:

PRINTPLAS-CI System Flexo Printing Machine PKF-6CI Series

LEEWIN-Chamber Dr. Blade Flexographic Printing Machine HSP-610-DR2

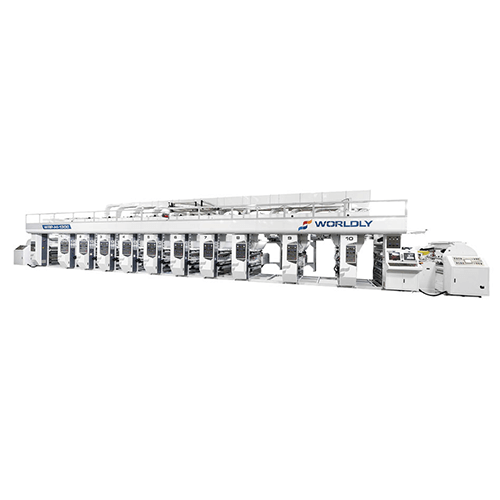

Rotogravure Printing Machine: The rotogravure printing machine is another commonly used printing machine in the plastic and rubber industry. It operates based on the principle of intaglio printing. The recessed patterns on the engraved plate hold the ink, which is then smoothed out by a rubber doctor blade and transferred onto the printing material through a printing cylinder. It possesses highly precise printing capabilities and excellent color reproduction.

The rotogravure printing machine is suitable for large-scale production and can print various plastic and rubber materials, such as packaging bags, films, wallpapers, labels, and foils. It is primarily applied in the packaging industry, including food packaging, beverage packaging, and household product packaging.,etc. With its ability to achieve high-speed printing and handle large quantities, the rotogravure printing machine stands as an ideal choice in the plastic and rubber printing industry, offering high speed, precision, resolution, and efficiency.

PRM-TAIWAN recommends high-quality Rotogravure Printing Machines for you:

WORLDLY - Computerized High Speed Rotogravure Printing Machine(WRP-HI Series)

Digital Printing Machine: Digital printing machines are gaining popularity in the plastic and rubber industry for their high flexibility, capability for personalized printing, and fast time-to-market advantages. These machines directly receive and process images and content from digital files using computer control for printing. They utilize non-contact printing methods with toner, ink, or electronic induction ink.

Digital printing machines offer the advantage of customized printing without the need for additional costs and time to create printing plates. They are particularly suitable for small-batch and diverse printing products, allowing for quick response to market demand changes. Digital printers are ideal for printing personalized products, print samples, digital photo printing, stationery and printed materials, as well as labels and packaging. They can achieve high-resolution label printing and are capable of color printing and customization on various packaging materials. Most of the masks printed during the epidemic were actually produced using digital printing machines.

The mentioned printing machine types find wide application in the plastic and rubber industry. Choosing the appropriate printing machine depends on specific printing requirements, such as the type of printing materials, printing volume, desired print quality, and production efficiency. Each printing machine type possesses unique advantages and features. Manufacturers and buyers should evaluate and select the most suitable option based on their actual needs.

PRM is a prominent media platform in the rubber and plastics industry. On the PRM platform, it brings together over 200 manufacturers and over 4,000 product listings. Global buyers can find various suppliers of printing machines and rubber/plastic machinery and obtain firsthand information about the rubber and plastics industry. If you have any further requirements, please feel free to contact us. We can assist you in finding suitable suppliers and help facilitate your business operations.