JANDI'S: Professional Technology and Innovation for a Green Future

頭條消息

JANDI'S: Professional Technology and Innovation for a Green Future

Facing the increasing problem of plastic pollution, various countries have introduced numerous plastic reduction policies and regulations in response to the growing problem of plastic pollution. In 2018, Taiwan implemented a plastic restriction policy aiming to reduce the use of single-use plastic items, including plastic straws, beverage cups, plastic shopping bags, and disposable tableware, with the goal of a complete ban by 2030. Many countries have already started banning plastic bags.

熱門訊息

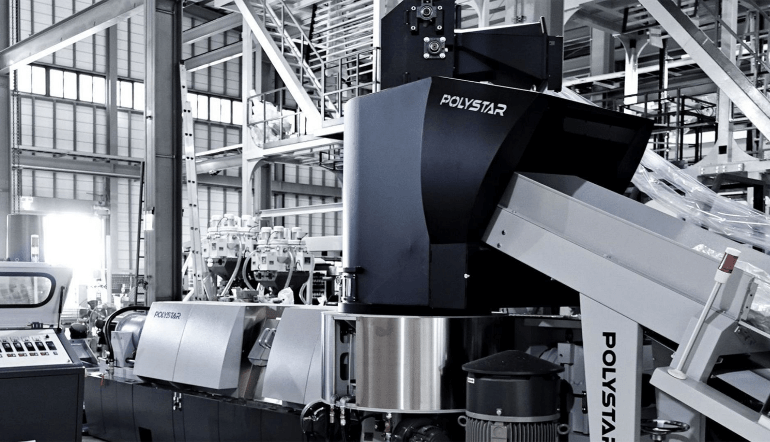

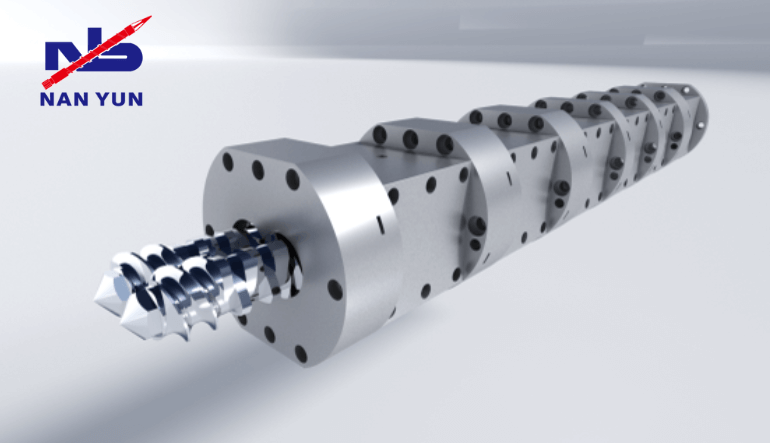

Sustainable Innovation in Extrusion Technology: NAN YUN’s Co-rotating Twin-Screws

Established in 1993, NAN YUN Industrial Co., Ltd. is a leading supplier of essential components for injection molding machines, extruders, and related machinery in the plastic and rubber industry. Our dedicated engineering design team combines exceptional theoretical knowledge with practical expertise, specializing in the meticulous design and production of a wide range of screws and barrels.

Explore the Future of Plastics and Rubber at TaipeiPLAS 2024!

TaipeiPLAS 2024 is more than an exhibition; it’s a gateway to the future of the plastics and rubber industry. Whether you are looking to discover the latest technologies, network with industry leaders, or enhance your knowledge, TaipeiPLAS offers invaluable opportunities. Join us at this premier event and be part of the innovation that is driving the industry forward. We look forward to welcoming you to Taipei, welcome to PRM’s booth: I1011!

Transition to a Bio-Based Economy: Worley Takes on FEED for Avantium’s New Plant

Worley has been awarded the front-end engineering design (FEED) contract to develop Avantium’s flagship plant, supporting the transition to a bio-based economy for plastics. This plant will produce 100% plant-based FDCA (furandicarboxylic acid), a crucial component for various chemicals and plastics.