JANDI'S: Green Innovation – The production of Cassava Bags

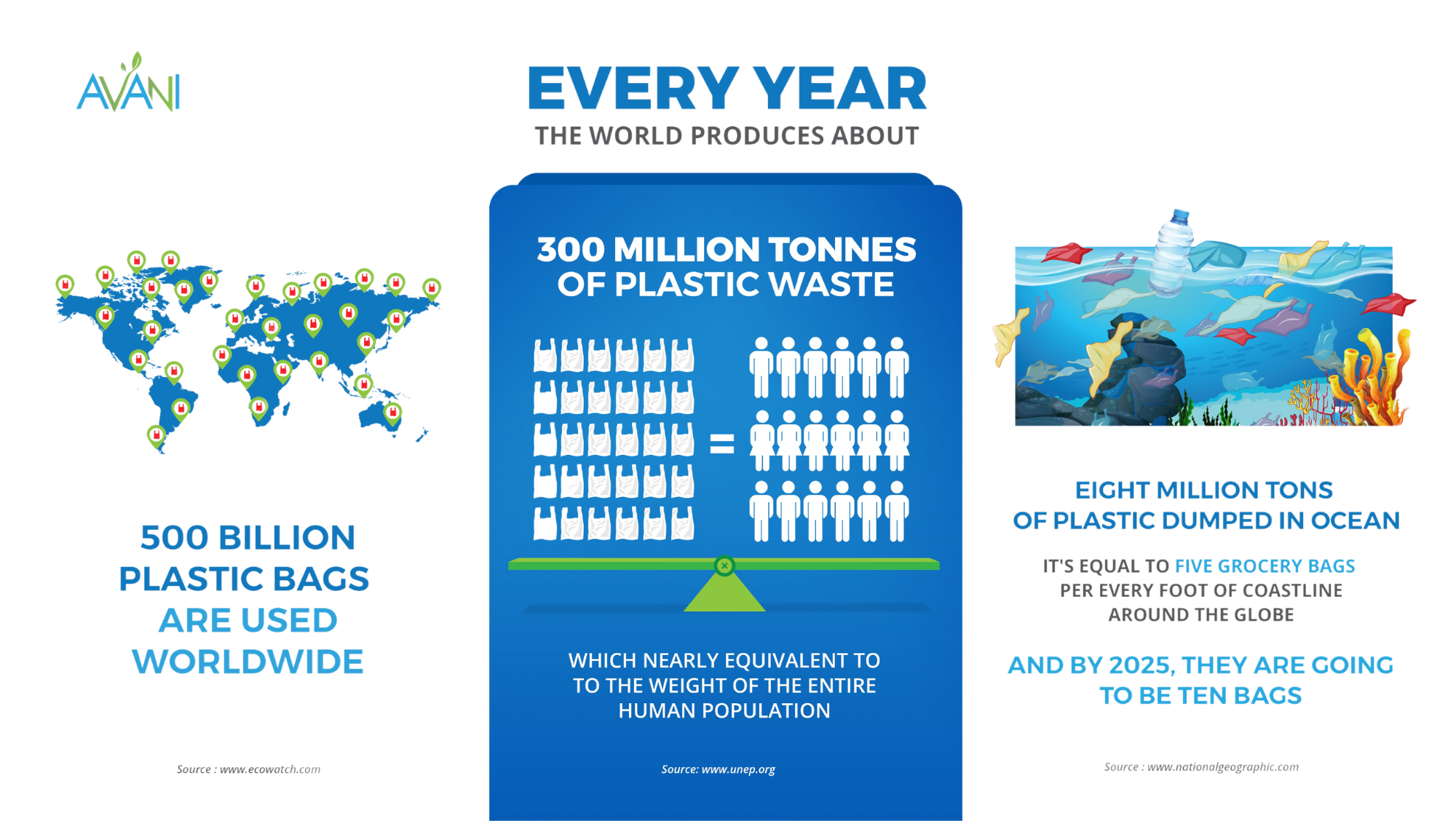

According to a thesis in 2023, about 100+ million tons of plastic bags yearly used all over the world, and during the production/use/disposal of plastic bags, each ton, about 3.3 tons of carbon dioxide is emitted into the atmosphere.

On the other hand, for each ton of biodegradable plastic bags, only about 1.19 tons of carbon dioxide is emitted, during their production/use and disposal. The difference of carbon dioxide emission could be more than 2.1 tons x 100+ million tons, which could severely make some difference to the climate change.

Biodegradable bags are compostable and could be processed into fertilizers that help to increase the production of agricultural products which also could be used for biodegradable bags, all into a very Eco-friendly recycle.

Mostly, the unit price of cassava starch is lower than other starches such as potato, maize and wheat starch. And, in 2018, about 280 million tons of cassava were produced, 61% from Africa, but more than 1/3 for cassava is wasted due to physiological deterioration, hence cassava is a good and reasonable source for biodegradable material. And, when disposed in the environment, cassava bags absorb moisture from the air and degraded between 3-6 months and soluble in water, river and ocean even faster. Contact us today to get more information about Turn-key project for production of Cassava bags.

We also provide blown film machine, printing machine, bag making machine and recycling machine for PBAT/PLA and other bio-degradable. And, JIT, all-in-one model provides you a much easier way to produce shopping bags with the material you choose.