T Shirt Bag Bag On Roll with core auto insert system - 32RTWDFA-VR-2

Plas Alliance has a variety of plastic bag on roll machines for customers to choose, and is committed to innovation and research and development. So far, it has developed a variety of bag making machines for various bag formats.

【T-Shirt Bag On Roll Making Machine Features】

High speed Continue feeding system available in 200/250/300rpm systems.

Tension-less sealing avoids sealing line pull & elongation for high-speed production.

Rotary Die cut by Magnetic cylinder with simple die cut blade exchange.

Inverter controlled feeding matching main machine speed for easy operation without manual adjustment.

Support to work for Jumbo film slitting into two separate roll with post gusset in line system by Option (or model : 36RTWDFA-VR+SLG2)

Equipped with LCD touch panel, easy to operate

Switch control to exchange bag making process without adjustment

Bag re-wind in roll , paper CORE insert in line automatic

End of Film, core auto STOP

【Machine Available System】

Tension-less sealing

T shirt bag on roll

Flat bag on roll

S type bag on roll

【Company Intro】

“PAL- Working with you to create all types of bag making automation solutions!”

Like the first companies in 1988 to create the first bottom seal bag machine started, and since then, we have been studying bag machine design, manufacturing, innovation and change with the bag, we have always kept up to date technology, continue to explore, develop more labor-saving, cost-saving bag machinery, to provide customers with a complete bag packaging solutions, growing up with customers, a business partner to create the pinnacle!

World Steel-Zipper Bag Making Machine

COSMO has many years of experience in bag making machines. We are still willing to have much more improvement and all the consumers are satisfied with the quality of machines offered to you.

【Machine Features】

2 lines coreless star sealed bag on roll making machine

Oscillation film feeding & sealing system for stability and high out put

Automatically reel changing system

High production efficiency to save manpower and time

Servo motor, as standard attachment, makes it easy to adjust the bag length and the production speed

Computer control over the entire process

From film roll to final bag, non-stop, one process flow

Automatically stop when running out of film/ film feeding blocks or bags jam/ color scanning misses

【Company Introduction】

COSMO Machinery Co., Ltd. established in March 2001, is well-known for Taiwan manufacturing plastic bag making machinery with servo driving systems. The product from COSMO has the servo motor as standard attachment, makes it easy to adjust the bag length and the production speed, computer control over the entire process, component self-testing function available, high production efficiency to save manpower and time. Up to now, COSMO products are extensively exported to 100 countries spreading all over the world.

COSMO has many years of experience in bag making machines. We are still willing to have much more improvement and all the consumers are satisfied with the quality of machines offered to you.

【Machine Features】

2 lines T-shirt bag on roll making machine

High production efficiency to save men power and time

Computer control over the entire process

From film roll to final bag, once process flow

Servo motor, as standard attachment, makes it easy to adjust the bag length and production speed

Automatic film feeding, coordination free from tension adjustment

Oscillation film feeding system for stability and high out put

Automatically stop when running out of film/ film feeding blocks or bags jam/ color scanning misses

Automatically core changing system

Punch system on magnetic roller

【Company Introduction】

COSMO Machinery Co., Ltd. established in March 2001, is well-known for Taiwan manufacturing plastic bag making machinery with servo driving systems. The product from COSMO has the servo motor as standard attachment, makes it easy to adjust the bag length and the production speed, computer control over the entire process, component self-testing function available, high production efficiency to save manpower and time. Up to now, COSMO products are extensively exported to 100 countries spreading all over the world.

COSMO has many years of experience in bag making machines. We are still willing to have much more improvement and all the consumers are satisfied with the quality of machines offered to you.

【Product Lines】

T-shirt Bag On Roll Making Machine

Bag On Roll Making Machine

T-shirt Bag Making Machine

Garbage Bag & Industrial Bag Making Machine

T-shirt & Bottom Sealing Bag Making Machine

Side Sealing Bag Making Machine

Air Cushion Bag Making Machine

Stretch Rewinder

Glove Making Machine

【Company Introduction】

COSMO Machinery Co., Ltd. established in March 2001, is well-known for Taiwan manufacturing plastic bag making machinery with servo driving systems. The product from COSMO has the servo motor as standard attachment, makes it easy to adjust the bag length and the production speed, computer control over the entire process, component self-testing function available, high production efficiency to save manpower and time. Up to now, COSMO products are extensively exported to 100 countries spreading all over the world.

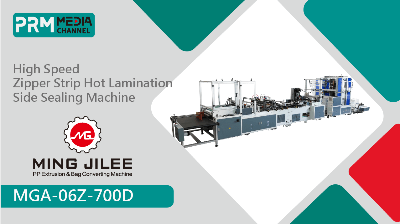

【Machine Features】

Taiwan-made and stable PLC controller

The size control of Zipper Bag Side Sealing Machine is by servo motor. Made in Japan.

Zipper Bag Side Sealing Machine is equipped mark sensor for printed material.

For getting the best quality of zipper bag product, unwinding station is mount the auto tension control.

The individual zipper strip unwinder with motor control to get the high quality of zipper sealing quality.

Ultrasonic welding is design by motor driven for highest speed production.

The ultrasonic welding station to crack the zipper on the edge of the bag for easy side sealing cutting.

【Company Intro】

Ming Jilee Enterprise Co., Ltd. is manufacturing film blowing machinery with materials of PP and LD/HDPE; PP thin and thick sheet making machine; waste recycling and pelletizing machine, stationery making machinery- can produce business file/data bag/file clip/photo pocket/name card pocket/index/bubble paper envelope; sealing & cutting machinery-side sealing bag/t-shirt bag.

All-Servo Drive T Shirt Bag On Roll Bag Making Machine ft. Swing Type Feeding System | PLAS ALLIANCE

T Shirt Bag Bag On Roll with core auto insert system - 32RTWDFA-VR-2

Plas Alliance has a variety of plastic bag on roll machines for customers to choose, and is committed to innovation and research and development. So far, it has developed a variety of bag making machines for various bag formats.

【T-Shirt Bag On Roll Making Machine Features】

High speed Continue feeding system available in 200/250/300rpm systems.

Tension-less sealing avoids sealing line pull & elongation for high-speed production.

Rotary Die cut by Magnetic cylinder with simple die cut blade exchange.

Inverter controlled feeding matching main machine speed for easy operation without manual adjustment.

Support to work for Jumbo film slitting into two separate roll with post gusset in line system by Option (or model : 36RTWDFA-VR+SLG2)

Equipped with LCD touch panel, easy to operate

Switch control to exchange bag making process without adjustment

Bag re-wind in roll , paper CORE insert in line automatic

End of Film, core auto STOP

【Machine Available System】

Tension-less sealing

T shirt bag on roll

Flat bag on roll

S type bag on roll

【Company Intro】

“PAL- Working with you to create all types of bag making automation solutions!”

Like the first companies in 1988 to create the first bottom seal bag machine started, and since then, we have been studying bag machine design, manufacturing, innovation and change with the bag, we have always kept up to date technology, continue to explore, develop more labor-saving, cost-saving bag machinery, to provide customers with a complete bag packaging solutions, growing up with customers, a business partner to create the pinnacle!

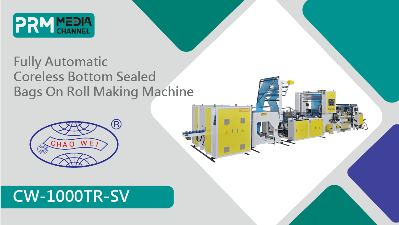

【Machine Spec & Features】

Bottom Sealed Bags On Roll Making Machine (Coreless)

Film width: 600 mm / Thickness: 15 micron

E.P.C Control & Rollers Device (E+L, German made)

Length: 750 mm x Speed: 135 Pcs/Min

Production Line Speed: 100M/Min

Servo Driven Shuttle Type Sealing & Perforating Unit

Two Sets Triangle Folders For Making Finished Roll With Small Width

Machine Maintains High Speed Production By 4 Sets Rewinding Shafts While Producing Small Quantity Of Bags Per Roll

【Company Introduction】

Chao Wei Plastic Machinery is an advanced manufacturer of plastic bag making machine with more than 35 years of experience with ISO 9001 & CE certificates in Taiwan. One of the reasons for the excellence of Chao Wei’s machines is our dedication to research and development.

【Feature】

High-speed servo-driven system

Special sealing system, keeping the production speed steady regardless of the film thickness and length

Convenient sealing knife system, with easy changeovers of sealing knives, making production more flexible

Unique perforating knife system for various film materials

Intellectual rotary interleaved winder with the 2-in-1 system applicable to bags on roll and interleaved bags

User friendly touch screen control system

Reliable & multi-functional system, capable of producing star sealed bags, wave type bags, table covers and many more through modular system changes

【Company Introduction】

Lung Meng Machinery also known as Dragon Plastic Machinery was established in 1976 as a professional plastics converting machinery manufacturer. In 1983 Dragon Plastic developed “All In Line System”, which allows blown film extruders, printers and bag machines to work together in-line. Lung Meng Machinery's wide range of innovative machines are the very solution to exceed customer's expectation at a satisfactory price. After 46 years of continuous research and development, Dragon Plastic has become the only company that can integrate all three kinds of machines together in an in-line process.

JANDI'S INDUSTRIAL CO., LTD. is committed to developing blown film machines combined with bag making, printing, and recycling machines. Until 2018, they obtained more than 30 patents of plastic machinery in China and Taiwan.

With the concept of plastic reduction raising, JANDI'S proposes an idea about green innovation. The company develops JIT series integrated plastic bag making machines that are 100% suitable with biodegradable and compost materials such as PBAT and PLA. Moreover, JANDI'S added the automatic packaging part to JIT series.

【SPECIALTIES OF HCI】

Slitting Machines

Rewinding / Inspection Machines

Pouch Making Machines

Medical Sterilization Pouch / Reel Making Machines

Shrink Sleeve Seaming / Cutting / Doctoring Machines

Embossing Machines

【ABOUT HCI】

Established in 1982, HCI Converting Equipment Co., Ltd. is a specialist in the design and manufacture of a full range of Roll-to-Roll and Roll-to-Sheet Converting Equipment and machinery for Flexible Packaging and Semi-Conductor, TFT-LCD, optoelectronics, Medical Industry (Sterilization Pouch/Reel Making Machine、Meltblown Fabric) and relative industries.

Suitable for a range of shapes folds and pockets, interlinking with other equipment to be able to make even more types of bags for easy exchange.

Pattern types include: punching equipment for round holes, butterfly holes, utilizes handheld punching equipment for accuracy and can produce perforations for letter and packaging tear off strips.

Using a vertical up and down heat sealing system and supersonic sealing line device.

Provide extra parts for improved production accuracy and quality, including EPC edge sensor, servo motor to drive the machinery and an automatic conveyor to get your finished products to the packing section as soon as possible.

Suitable for already perforated and/or folded films.

【Company Introduction】

World Steel Machinery Company is dedicated to making technological innovations and manufacturing packaging machines.They have the best engineering crew in the industry to provide total solutions which include design, customization and development. If you are looking for machines that produce, flower sleeves, diaper bags, book sleeves, self adhesive bags, handle bags, sandwich bags or more, then World Steel is the best choice for you.