We are here with Ms. Ada from the CHINAPLAS. She also shared very useful information about the forthcoming CHINAPLAS 2024 including the focus of the exhibition.

We at NPE invited PLASTICS Marketing Director Damaris to be interviewed by us. Sharing the latest news at the 2024NPE exhibition, there were 50,000 visitors on the third day of the exhibition. This is something very happy about.

It’s our great honor to interview Mr. Aldimir Torres Arenas from ANIPAC He shared his insight for the China and Mexico market. Check our video for more information!

It’s our great honor to interview Mr. Marcelo Zimmaro, Machinery and Accessories Sectorial Chamber for the Plastic Industry from ABIMAQ SINDIMAQ Brazil. In this interview, Jason asked him about ABIMAQ's services and business scope, his views on the economic situation in Latin America in recent years, and his expectations for this exhibition in China. Mr. Marcelo Zimmaro stated that their mission at the exhibition is to assist the Brazilian machinery industry in import and export activities, and they hope to find more allies and friends at this exhibition. For more detailed interview content, please stay tuned for the upcoming PRM reports. PRM is committed to collaborating with global media to bring more information about the world's plastics and rubber industry to everyone.

ISOTHANE Bio TPU

Sustainable bioplastics derived from natural plants, Make life more energy efficient and make the world a better place to live.

It's our great honor to interview WEI MENG and their Turkish agent in the 2023 PlastEurasia.

Watch our video for more information!

Check our on-site tour video for Plastics & Rubber Indonesia 2023!

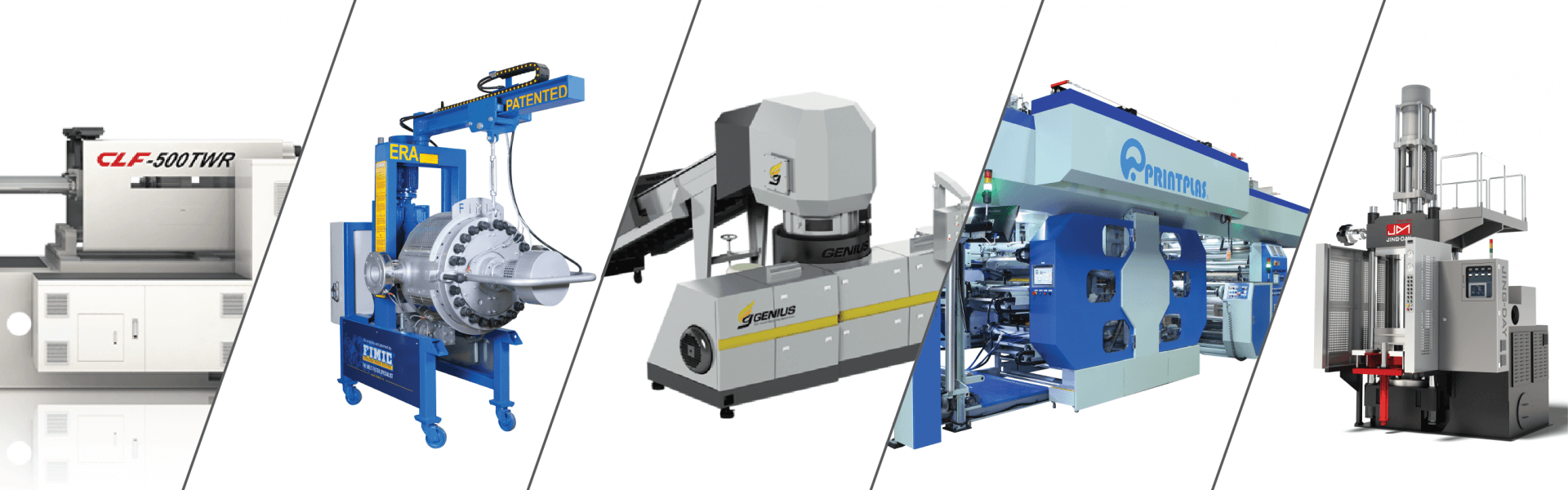

Taiwanese suppliers, which is specialized in the Plastic & Rubber industry, known as its high quality machinery. If you don't want to miss out the latest news, stay tuned!

It's our great honor to interview Tracy from Chan Chao. Tracy also introduced their services in holding worldwide exhibitions.

It's our great honor to interview Jenny from CLF, introducing their injection molding machine TWII 250.

VietnamPlas is an important exhibition in the plastic and rubber industry.

Watch the on-site tour video from VietnamPlas for more information!

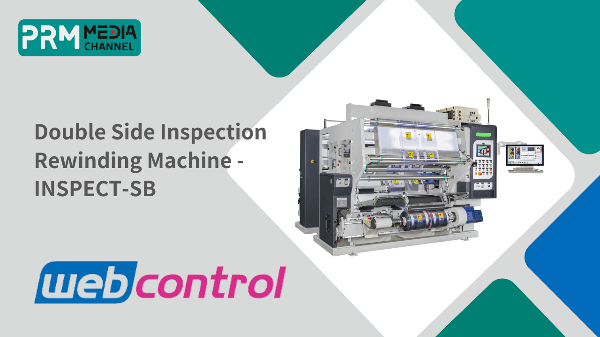

The double side inspection rewinding machine is designed print roll inspection. This model is able to inspect both sides of the material simultaneously to ensure the best quality in the minimum time.

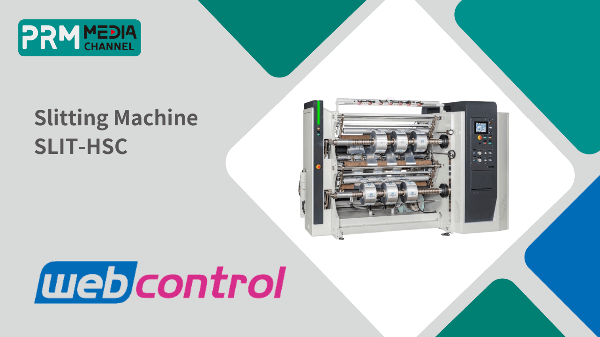

The SLIT-HSC series slitter is new compact type to save the working space. From the unwind side, the web is guided middle to the main machine, easy access to the slitting section and eliminates dust collection/hazarded steps. The slitter comes standard with razor cutters and groove roller configuration. A shear cutter system is offered as option for paper and other pressure sensitive materials. The machine uses three AC Vector Drives and has automatic tension on unwind and rewind controlled through easy-to-use PLC & MNI touch screen. Friction rings are used on rewind shafts to ensure the production of quality slit rolls when the film thickness varies.