Positioning swop as a Packaging Industry Leader: Insights from Adsale’s VP, Rita| Shanghai swop 2024

In my latest interview at swop, I had the honor of speaking with Rita, Vice President of Adsale, one of the key organizers of this impactful exhibition. Rita shared her perspective on how Adsale strategically positions swop as a cornerstone for the packaging industry, fostering meaningful connections and driving innovation. She also revealed Adsale’s core mission behind organizing exhibitions like swop and how they contribute to shaping the future of the industry. Curious about how swop creates value for packaging professionals worldwide and what to expect from this pivotal event? Don’t miss Rita’s insights and her vision for swop’s role in the global packaging ecosystem.

Injection Molding Process & Benefits | PRM What to Say EP10

Have you ever wondered how daily used plastic materials are made? Plastic materials are a part of our everyday life. Many of them are made by Plastic Injection Molding process. Starting from toothbrushes, cups, plates, automobile parts, hand tools, electric and electronic hardwares, and so on. So, why is plastic injection molding commonly used for plastic materials manufacturing? We answered these questions and listed 6 benefits of the plastic injection molding process for you. Come take a look at the video to discover more about the plastic injection molding machines and production process.

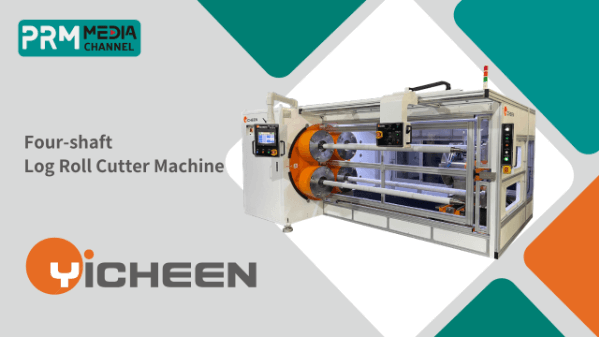

Automatic Log Roll Cutting Machine|Four-Shaft Log Roll Cutter | Yicheen

Automatic Log Roll Cutting Machine can be applied to cut rolls of various tape materials, such as double-sided tape, electrical tape, masking tape, construction tape, etc.. More product info: ???? https://bit.ly/3q8uLWw / Automatic Log Roll Cutting Machine Features / Cutting running is driven by AC motor with inverter control. Fast and stable to speed up & down. PLC control system Auto change cut size setting in the same shaft. Precise and smooth positioning. Multi-speed cutting rolls to improve operating efficiency and maintain high quality. The blade has different angle changes according to different materials, reducing the number of tool changes. / Advantages of Yicheen / Leading the industry in the research and development of the Die-Cutting Machine". In addition to the continuous improvement of technology, it has also developed a variety of Printing Machines, Laminating Machines, Cutting Machines, Sheet Cutting, Slitting Machines, and other equipment to provide complete plastics Processing equipment solutions. / links of Yicheen / Contact us: https://bit.ly/3q8KLaK Subscribe us: https://bit.ly/3wGjjU3 Product Info: https://bit.ly/3tU2QdK

CHINAPLAS 2021 PRM Trade Show Activities | PRM Media Channel

Throwback to CHINAPLAS 2021 to share the online and offline events of PRM. More Info About PRM Online Exhibition: https://bit.ly/3f1UN8t Let's take a look at PRM Trade Show Activities related to this biggest plastics and rubber industry exhibition in Asia. It was our pleasure to attend CHINAPLAS 2021 this year. Since the pandemic, the foreign visitors and exhibitors have been fewer than in previous years; however, PRM understands our customers' and international buyers' circumstances. In this video, you will find our exhibition activities, including matchmaking buyers and manufacturers of the plastics and rubber industry through our in-time inquiry system. During the exhibition, PRM observed the Chinese market and CHINAPLAS, also we have interviewed exhibitors to gather more profound insight into the market. You can find detailed information on our Youtube Channel, E-newsletter, and social media platforms that are provided below. We also cooperated with Adsale, the organizer of CHINAPLAS, to bring out interview videos and the Livestreams about the current situation of the plastics and rubber industry and their solutions. For more information and videos, please visit our PRM-TAIWAN TechHub@CPRJ at https://bit.ly/3f1UN8t Follow PRM Media Channel on: YouTube: https://www.youtube.com/c/PRMTaiwan Facebook: https://www.facebook.com/PRMTAIWAN Linkedin: https://www.linkedin.com/company/prm-taiwan/

User Feedback from Azin Polymer | K 2022

It was an honor to interview Mr. Arash Alivirdi, a sales manager form Azin Polymer, at K 2022. He has been using PRM-TAIWAN for ten years. Let's listen his experience in using PRM-TAIWAN as a major platform for seeking machinery suppliers.

JIT-SS |JIT T-Shirt Bag Making Line- |JANDI'S

Blown Film→Printing→Bag Making→Die-Cut Recovery, from resin to finished bags, ALL IN ONE PROCESS. HDPE / LDPE / Biodegradable / Compostable Material AVAILABLE

How Machines Shape Every Shot: The Engineering of a Golf Ball

Every perfect shot starts with precision engineering. In this video, we take you inside the manufacturing journey of a golf ball — from the resilient rubber core to the durable plastic outer shell. Watch how advanced molding machines, material processing systems, and pad printing technology come together to shape every ball with accuracy and consistency. You'll see how multi-layer construction enhances performance, how dimples help stabilize flight, and how automation ensures uniformity from core to cover. Whether it's molding, printing, or aerodynamic design, every detail is crafted by machines built for precision. This is the engineering behind every swing. This is how machines shape every shot. Powered by Taiwan's leading machinery manufacturers, and brought to you by PRM-Taiwan — your trusted platform for discovering top suppliers and cutting-edge plastic & rubber processing solutions.

2024 CHINAPLAS Interview | HCI

We are here with Terence from HCI Converting Equipment at the CHINAPLAS. HCI is a specialist in the Converting Equipment and Slitter Rewinder machinery, able to provide from a single machine to whole plant equipment. We heard very valuable information from Terence, thank you so much!

Customization & After-sale Service | GENIUS

More and more countries request all plastic-made products to be fully recycled; therefore, plastic recycling machines have been important. Mr. Peter Tsai, the general manager of Genius, explained the best seller “Single Stage Cutter Compactor Plastic Recycling Machine” as known as KRIEGER series in their product lines. This machine is capable of recycling HDPE drums and films with superior features, such as Italian-made heater, extruder-degassing vents, dual piston filters. With excellent customer satisfaction and customization service, Genius awarded an order from a returning Japanese client again. According to the language and the use habits, the parts of the machine have been installed with many Japanese brands in order to lessen obstacles while Japanese employees operate the machine. Moreover, Peter has expressed how Genius values customer satisfaction, customization service and after-sales service in the interview. Through this video, you will be showcased how Genius is running the testing of Single Cutter Compactor Machine before shipment. 【Brief Intro】 Genius Machinery specializes in the comprehensive plant planning of plastic recycling equipment. With over 40 years of experience in designing and manufacturing plastic recycling equipment. 【Video Outline】 00:00 - Introduction 00:31 - Machine Testing & Superior Features 02:10 - Conveyor Belt 02:19 - Compactor 02:50 - Extruder-degassing 03:19 - Dual Piston Filter 03:40 - Pelletizer 04:18 - Details of customized control panel 05:21 - Materials Process & Applications of Machine 06:27 - After-sale service for installation & maintenance 08:05 - Messages to customers

Mold Cart | FORWELL

Mold Cart - Mold Cart System-Forwell Features -Fully automated die or mold changing - High precision die or mold placement - Increased safety and efficiency - Can serve multiple production lines at once - Multiple layout configurations System Introduction : Forwell's Die / Mold Cart System provides automatic die or mold changes for a range of different machines, such as plastic injection molding machines, plastic extrusion machines and press machines. This Die / Mold Cart system offers very fast, efficient and safe die and mold changes, using an advanced cart on rails system. Conventional die or mold changes can often take over an hour, but with the Die / Mold Cart System, die or mold changes are automatically completed in just a fraction of the time. Using this system, all procedures from die transfer and changing, to positioning and clamping is carried out by this system, resulting in extremely accurate die or mold changes. As the Die / Mold Cart System offers very precise die or mold changes, many operational issues can be avoided such as locking screws breaking when hand tightened, and incorrect mold alignment resulting in damage to the mold or production equipment. The Die / Mold Cart System also massively increases safety and efficiency, by allowing for automatic operations and making it feasible to perform many small batch production runs. Another great feature of this system is that it can be configured to specific user needs, different production facilities and serve multiple production lines at once.

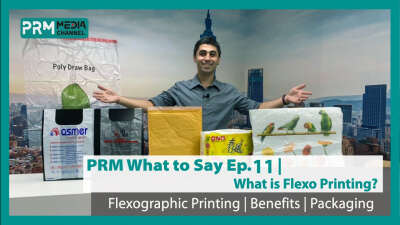

5 Benefits of Flexo Printing Machines | PRM What to Say EP11

There are several types of printing techniques available for the plastic packaging industry. Such as flexo printing, offset printing, and screen printing. Although flexo printing is not a new technology, it is the most common method for packaging printing. Then let’s take a glimpse of the video to understand what flexo printing is and what makes it most preferable. Flexographic printing is a technique that uses a flexible printing plate. The plates are wrapped around cylinders on a web press. The inked plates have a raised image and rotate at high speeds to transfer the ink through small holes from the anilox roll to the substrate, which is the printed surface. So, what makes flexo printing the most common method? You will find 5 reasons why in the video.

Business Tips of Choosing Plastic Recycling Machine | PRM What To Say EP17

Do you understand different kind of plastic recycling machines? Each type of plastic could be processed by certain type of machine. If you are still confused in choosing machines for your business, you must watch this video.

Screws / Barrels for Extrusion and Injection Molding | NAN YUN

As leading company of Screws and barrels in Taiwan, Nan Yun is able to provide the highest quality screw and barrel for Extruder Machine. We are continually researching new screw and barrel materials that would best fit the needs for pellet extruder or plastic pelletizing machine, which results in better mixing, and critical melt quality. Nan Yun's engineers work with our customers to provide the best possible extruder screw design for extruder machine such as PVC pelletizing machine, PE pelletizing equipment, Plastic pellet extruder.

Live Broadcast of High-quality MIT Suppliers | 2022 Taipei Pack

This year, Taipei Pack Exhibition will continue to exhibit various types of packaging machinery, materials, and logistics from different Taiwanese Manufacturers. Of course, PRM Media Channel will continue to attend this year's exhibition with LIVE STREAM video interviewing different manufacturers and giving you insights about their machinery technologies and functionality. Event: Taipei Pack Exhibition Date & Time: June 23, 2022 , 15:00 (GMT+8) Location: Taipei Nangang Exhibition Center, Hall 1 (TaiNEX 1) If you are looking for a packaging machine or packaging relevant suppliers, We, PRM MEDIA CHANNEL, invite you to watch this LIVE STREAM! Stay tuned!

Sustainable Innovation of Blown Film Machine | KUNG HSING-

The latest innovation of Three Layer Blown Film Machine is featured with 3 in 1 Gap Winder that combines Surface Type, Contact Drive Type and Gap Winding. We are pleased to invite Kung Hsing Machinery to share the insight of the Blow Film Industry with us, which includes application, ESG and the effect of geopolitic to the economy.

Hydraulic Slitter and Cutting Machine | Yicheen

Hydraulic Slitter and Cutting Machine

2024 TaipeiPlas International Plastics & Rubber Industry Show| CHUAN LIH FA

At the TaipeiPlas, PRM-Taiwan interviews CHUAN LIH FA MACHINERY WORKS CO., LTD. In this exclusive feature, CHUAN LIH FA demonstrates their latest custom-designed injection molding machines, highlighting innovations that push the boundaries of technology in the plastic injection molding industry. In this video, you'll learn how their new machines offer significant space-saving designs, as well as the ability to handle multi-color production, making them a versatile solution for manufacturers. Discover how CHUAN LIH FA is not only advancing technology but also fostering talent and driving progress in this dynamic industry.

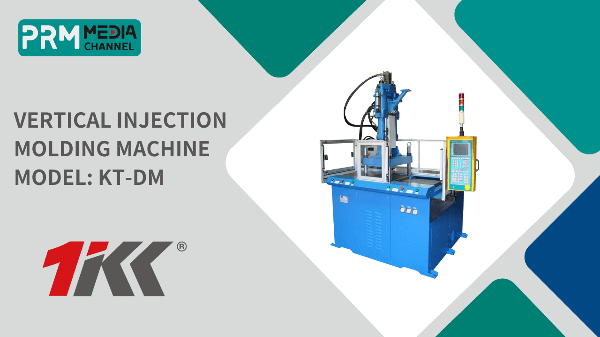

Vertical Injection Molding Machine - KT 300 | TAIWAN KINKI

FEATURES: 1.Vertical mold clamping and injection, small footprint, and high degree of precision. Our Vertical Injection Moulding Machine is ideal for the injection of medium and small products with inclusions. 2. Direct-pressure mold clamp allows even injection force, and the relatively low pressure means maximum precision and an incredibly smooth cycle of operation. 3.KT-300 Vertical Plastic Injection Molding Machine offers a wide range of programmable functions including automatic inclusion, extraction, and fully-automatic production. 4. Dual-cylinder injection system offers high injecting pressure for fast operation, making this injection machine your best choice for the production of thin items. 5. Choose a platen or a rotary plate in accordance with the type of products to be injected, in order to achieve the best possible in feed and injection effects. 6. There are also many other control systems that facilitate flexible production and keep costs low while maximizing precision.

Flying Knife Cutting Bottom Sealing Bag Making Machine, MGA-BSF-1000W | MING JILEE

Flying Knife Cutting Bottom Sealing Bag Making Machine, MGA-BSF-1000W For Further information:https://www.mingjilee.com/en/product/Wire-Impulse-Bottom-Bag-Sealing-Machine-with-Flying-Knife-Cutter.html

Full Electric Co-EBM with visi strip (4 head double station) | CM-90.55FVH2D | Chia Ming

CM-FE90.55FVH2D Full Electric Co-Extrusion Blow Molding Machine - Continue extrusion with horizontal movement and toggle clamping. Fully automatic and highly efficient production. -------------------------------------------------- Why Go Full-Electric? ► Energy savings 20%~70% ► Precise and more efficiency ► No hydraulic, less noise, no oil leakage ► Easy maintenance -------------------------------------------------- / Key Features / ★ All-electrics (Fully servo motor driven) ★ Servo Drive Die Head Nodding System ★ Full Electric Parison Control System ★ Crank Type Servo Drive Carriage Movement ★ Visi Strip function ★ Auto deflashing device ★ Backhoff, Germany and Keyence, Japan control system -------------------------------------------------- / Other Features / ★ Equipped with robot arm (2D Gripper) ★ Post cooling ★ Auto loading system ★ Residue conveyor to crusher ★ Built by standard components, i.e. Beckhoff, Festo, SMC, Toshiba, Tokimec, Schneider, ABB, Omron, ensuring straightforward maintenance at lower cost and global spare parts availability -------------------------------------------------- / Optional equipment or function/ ????Support the “Industrial” internet of things. (More info, please contact.) -------------------------------------------------- / Application/ Jerrycan/ Food packaging/ drinks/ detergents/ reagents/ cosmetics/ medicines/ engine oil bottles/ lubricants/ jars/ home products/ car parts/ decoration parts...

Best Choice Of PET Extrusion Pelletizing Machine Line From Partico Machinery, Inc | PARTICO

Model no:HF-FTO-135 3 in 1- Flow Channel Pelletizing System Double Filters system: no.1 Double pistons(Back flush) no.2 CPF Spec:The dia of screw 135mm Output:500-600kg/hr Application:PET yarn, flakes, fiber, filament

High Speed PP/HDPE Raffia Tape Extrusion Plant | Raffia Tape Extrusion Line | HAO YU

【New generation high speed PP/HDPE raffia tape extrusion plant - GV series (Green Veloz)】 / Raffia Tape Extrusion Line/Plant Features - (HY7/SP-80GV) / ⚡️Suitable for making 100% recycle PP/HDPE materials ⚡️Finish products complies with the requirement of GRS(Global Recycled Standard). ⚡️Meet the requirements of companies interested in selling their products to ESG approved companies. ⚡️Rapid color changing.

Robot Arm, Take Out Robot, Injection Robot | ALFA ROBOT

Robot Arm, Take Out Robot, Injection Robot | ALFA ROBOT Originated from the parent company Alfa Auto Machinery Co., Ltd, Gamma is established based on the specific needs of customers. The chairman of ALFA, Mr. Shi Fuxing founded Dongguan Gmtek Technology Limited and Suzhou Gamma Automation Tech Co., Ltd in 2006 with the foundation of 2 million US dollars. The main services of Gamma are precision machining and professionally developed and manufactured high speed vertical machining center. Since the establishment, Gamma strives to fulfill the requirements of the customer and continue to provide the customers with the best service no matter if it’s precision, machining speed , the cost performance or the flatness.

Solventless Lamination - Webcontrol

Solventless Lamination - Solventlless Laminator-LM-SF1300-Webcontrol Webcontrol Machinery Corp has been specializing in manufacture of Solventless Lamination since 1988. Webcontrol ceaselessly develop new machine to extend production line for meeting various needs of customers. In additions, we constantly improve our Solventless Lamination with new technology, and innovate to enhances its performance, efficiency and reducing waste on production. Our consistently aim is to build high-performance, sophisticated Converting Machinery with inexpensive price as well as providing fast Solventless Lamination service ensure our worldwide customers must be satisfied.