Plastic Recycling Machine, Repro-Flex | POLYSTAR

【Machine Features】 The one-step plastic pelletizing machine, Repro-Flex, combine cutting, extrusion, and pelletizing into one compact and efficient pelletizer line. The cutter-compactor of the plastic pelletizing machine prepares the plastic waste (PE plastic film and PP plastic film waste) into an ideal condition for the extrusion process and feeds the plastic waste directly into the extruder. This integrated system does not require a separate crusher, and therefore, eliminates the problem of inconsistent feeding, reduces space and labor costs, and has lower energy consumption. Simple in Design. Flexible in Operation. POLYSTAR is able to customize its machines regarding customers’ needs. How this pelletizing system works: 1. Feeding a. By belt conveyor Feeding of scraps is easy and automatically controlled depending on the amount of material input. b. By Nip roller Film-on-rolls can be fed at the same time. 2. Cutting and compacting The cutter compactor integrated cuts, dries, and compacts the material which enables a fast and stable feeding from the compactor directly into the extruder. 3. Degassing system The two-zone degassing can process plastic film with larger printed areas. 4. Filtration Screen change with a dual channel system for non-stop operation that also prevents plastic material from leaking. 5. Pelletization Water-ring pelletizing system, also known as hot die face pelletizing, the plastic comes from the recycling extruder and is directly cut by the rotating knives attached to the surface of the die head. 6. Final Product Round-shaped recycled pellets are produced and cooled inside the water ring immediately. 【Company Intro】 Headquartered in Taiwan, POLYSTAR has focused on the user-friendliness of its machines through continuous re-engineering, making recycling extremely “Simple” for its users – Easy operation and maintenance is what makes POLYSTAR the No.1 selling recycling machine today. Over the past 32 years, more than thousands of POLYSTAR recycling machines have helped worldwide plastic producers to reprocess their post-industrial (in-house) waste back into high-quality pellets in a simple and easy way.

High Speed T Shirt Bag Making Machine|PLAS ALLIANCE

T Shirt Bag Bag On Roll with core auto insert system - 32RTWDFA-VR-2 Plas Alliance has a variety of plastic bag on roll machines for customers to choose, and is committed to innovation and research and development. So far, it has developed a variety of bag making machines for various bag formats. 【T-Shirt Bag On Roll Making Machine Features】 High speed Continue feeding system available in 200/250/300rpm systems. Tension-less sealing avoids sealing line pull & elongation for high-speed production. Rotary Die cut by Magnetic cylinder with simple die cut blade exchange. Inverter controlled feeding matching main machine speed for easy operation without manual adjustment. Support to work for Jumbo film slitting into two separate roll with post gusset in line system by Option (or model : 36RTWDFA-VR+SLG2) Equipped with LCD touch panel, easy to operate Switch control to exchange bag making process without adjustment Bag re-wind in roll , paper CORE insert in line automatic End of Film, core auto STOP 【Machine Available System】 Tension-less sealing T shirt bag on roll Flat bag on roll S type bag on roll 【Company Intro】 “PAL- Working with you to create all types of bag making automation solutions!” Like the first companies in 1988 to create the first bottom seal bag machine started, and since then, we have been studying bag machine design, manufacturing, innovation and change with the bag, we have always kept up to date technology, continue to explore, develop more labor-saving, cost-saving bag machinery, to provide customers with a complete bag packaging solutions, growing up with customers, a business partner to create the pinnacle!

雙用式無芯捲取袋製袋機

Flexible production with star sealing and bottom sealing. Shuttle system & 4 shafts re-wind system for stability and high out put. Servo driven system for high production capacity. From film roll to finished bag roll, computer control over the entire process. It's easy to adjust the bag length, film tension, and production speed on touch screen. Servo motor, as standard attachment, makes it easy to adjust the bag length and the production speed. Auto reel changing device and bag pull off device on re-winder. Automatically stop on miss-color scanning / film breaking / running out of film. MODEL SR(2)MR(1)-1000-OS-2T-R4S Bag Length 350 - 1500 mm Finished Product Ø150 x 600 mm (single line) Ø150 x 250 mm (2 lines) Film Thickness 0.008 - 0.060 mm / layer (bottom seal) 0.008 - 0.035 mm / layer (star seal) Film Roll Size Ø1000 x 900 mm (single roll for bottom sealing) Ø1000 x 500 mm (2 rolls for star sealing) Production Speed 150 meter / min / line (max) Power 220V, 3Phases, 50/60HZ, 30KVA Heater 6.2 KW Required Air Compressor 6HP (not included) Dimension L10000 x W2600 x H2500 mm * 規格如有變更改進,恕不另行通知。

Film/Bags Waste Plastic Recycling Machine - KCR-85 | KANG CHYAU

Inquiry and More Info: https://bit.ly/3hVGAvO Introducing the Film/Bags Waste Plastic Recycling Machine from one of the pioneering plastic recycling machinery and film extruder manufacturers in Taiwan, KANG CHYAU. Please click the link above for more information and/or inquiry, which will direct you to the manufacturer. For any assistance, PRM will be more than happy to assist. Contact us through our social media platforms or leave a comment below. Then we will reply and contact you asap. Machinery in the video: Film/Bags Waste Plastic Recycling Machine Model No: KCR-85 Output:80-120 kgs/hr Screw Diameter: Ø 85mm Single Dega Sification Suitable Materials: HDPE/LDPE/LLDPE

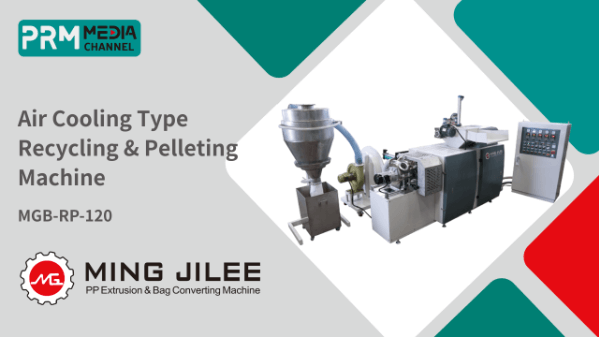

Air Cooling LD/HDPE Recycling Machine, MGB-RP-120 - MING JILEE

Air Cooling LD/HDPE Recycling machine is designs for re-pelletizing PE plastic waste material / t shirt bag die cut wasteThe material can be PE blown film waste, T shirt bag handle die cut waste, etc... Air Cooling Type Plastic Recycling Machine is equipped the power save, the SCR power regulator control. The real power consumption is around 15~20 kg. 1. Machine Specification: (1) Machine dimension a. Main machine : 2,770 (L) × 2,530 (W) × 2,060 (H) mm b. control box : 920 (L) × 420 (W) × 1,660 (H) mm (2) Machine weight : 2,430 kg (3) Power preparation : 45 kg (4) Power consumption : 20 kw 2. Machine Performance: (1) Applicable resin : LDPE / LLDPE / HDPE Waste Film (2) Output a. LD/LLD PE : 50 - 60 kg/hr b. HD/ PE : 40 - 50 kg/hr Air Cooling LD/HDPE Recycling Machine Features: (1) SCR power regular for saving power (2) Rotating die cutting head to get good quality of cutting shape (3) Less space required (4) Extra Cooling fan to cool down the PE material. Air Cooling Type Plastic Recycling Machine Further information: https://www.mingjilee.com/en/product/...

2024 InterPlas Thailand Interview | Chang Horing

We had the pleasure of interviewing Chang Horing Rubber Group, a leader in the rubber compound industry with over 20 years of experience, at Thailand InterPlas 2024. In this engaging conversation, they shared their expertise in developing and customizing rubber compounds for various industries, including automotive, chemical, heavy-duty, food, and water sectors. Chang Horing's dedication to quality and precision is evident in their state-of-the-art facilities, equipped with advanced systems and instruments to ensure high-quality consistency. They also discussed their future plans and initiatives related to Environmental, Social, and Governance (ESG) practices, highlighting their commitment to sustainability and innovation. We thank Chang Horing Rubber Group for sharing their valuable information and look forward to seeing their continued success in the industry.

Five Layer Blown Film Line | Multilayer Blown Film Machine | Blown Film Extruder - Kung Hsing

/ Kung Hsing Main Products / K.S. manufacture Agricultural Blown Film Machine, Inflation making machine, Flat Yarn making machine, Plastic strapping band making machine, Plastic Recycling Machine, as well as special design for all extrusion system machineries and whole plant projects. #KUNGHSINGPLASTICMACHINERY #BLOWNFILMLINE #MULTILAYERBLOWNFILM

EPS Foam Sheet Machine | Plastic Extruder Manufacturer | ChiChang

EPS Foam Sheet Machine can be widely used in packaging materials, such as food trays, eps food Packaging. Learn more https://www.extrusion.com.tw/en/products.html Contact Us https://www.extrusion.com.tw/en/contact.html / EPS Foam Sheet Machine Features / Machines provide customized services. Application: Food Tray / Packaging Material. Output: From 200 kg/hr. to 720 kg/hr. for EPS. Configure a color screen to instantly view productivity. Safe and high quality. / About Chi Chang - Plastic Extrusion Machine Manufacturer / Chi Chang have been committed to the design and fabrication of extrusion equipment for over 45 years. Our user-friendly and performance-oriented innovative technology reduces the operating workload of workers, reduces the operating costs, increases the overall production capacity and this in turn generates more profit. You can rely on Chi Chang to simultaneously secure both profit and quality for our clients.

JIT-SS |JIT T-Shirt Bag Making Line- |JANDI'S

Blown Film→Printing→Bag Making→Die-Cut Recovery, from resin to finished bags, ALL IN ONE PROCESS. HDPE / LDPE / Biodegradable / Compostable Material AVAILABLE

rPET Bottle for Household Packaging Solution | ChumPower

Over 40 years of history, CHUMPOWER is the largest PET blow molding machine manufacturer in Taiwan, and the CHUMPOWER PET blow molding machines made in Taiwan are in stable operation in more than 115 countries. 【Product Appliance】 Beverages Water Edible Oil Daily-used Cosmetics 【Product Range】 One Stage Injection Blowing Machine Injection and Bottle Molding Manufacturing Stretch Blow Molding Machinery Sales / Turnkey Solution TS Series Models for Lower Production Output (Suggest to new market players) Linear PET Blow Molding Machine (Suggest to buyers who is looking for higher output) 【SS10-rPET Single-stage PET Bottle Blowing Machine】 Hybrid hydraulic system with an optimized clamping mechanism to ensure Energy Efficiency Barrier screw with venting capability can effectively lower the energy required for drying Adopt 4 station design Non-contact feature Reach the trending topics of ESG, Carbon Neutrality, and Net-Zero Emission

3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine | GEORDING

3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine - GEOR-DING MACHINERY CO., LTD.. We specialize in manufacturing of 3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine. The main businesses include: 3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine and planning of entire plant’s equipment. While the demand for output and quality in 3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine worldwide is increasing day by day, our determination for upholding the motto, "Quality is number one. Output comes second. Customer satisfaction. Perfect service”, will never shift. Under your support and encouragement, we will continue to provide quality 3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine products and services to higher standards.

2023 IPF 孟加拉展廠商採訪 | 華周工業 HCI

來到 IPF 孟加拉展現場,我們當然不能錯過已經在孟加拉市場經營多年的華周工業,這次邀請到了華周的 Jacky 來分享他對於孟加拉工業的觀點以及台灣是如何在孟加拉做生意的。是否跟其他地區的市場經營不同呢?讓我們來一起看華周 Jacky 的分享吧!

User Feedback from Azin Polymer | K 2022

It was an honor to interview Mr. Arash Alivirdi, a sales manager form Azin Polymer, at K 2022. He has been using PRM-TAIWAN for ten years. Let's listen his experience in using PRM-TAIWAN as a major platform for seeking machinery suppliers.

2024 CHINAPLAS Interview | BoReTech

We are here with Mr.Alan Ou from ZHEJIANG BORETECH ENVIRONMENTAL ENGINEERING CO., LTD. at the CHINAPLAS. BoReTech is a leading company in the plastic recycling industry, that strives to solve plastic waste and give it a second life. With more than 30 years of experience in the industry, BoReTech can process different materials from different countries and gain know-how experience.

Blown Film Extrusion Line | FONG KEE

Blown Film Line - Three Layer Co-Extrusion Blown Film Line Located in Taiwan, FKI is the manufacturer of Three Layer T-Die Co-Extrusion Cast Film Machine. The demand of the Mono Layer/Multi layer T-Die Cast Film Extrusion Line has became more and more, which widely involved in many applications of packaging field, such as: 1. Decoration film 2. Gift wrapping film 3. Flower wrapping film 4. Stationery product packaging film 5. Lining film for dry/wet lamination 6. Sanitary product packaging film 7. Flexible packaging film 8. High barrier food packaging film With its outstanding optical and physical properties, either the mono layer or multilayer cast film being widely used in many applications, due to the well developed materials grades and additives, plus the well designed processing equipment with high precision control system as a full package to set the positiveness.

ELS High Speed Rotogravure Printing Machine | WORLDLY-

High-Speed ELS Rotogravure Printing Machine WRP-HHI-1300-10C series | WORLDLY Machine Specifications - Max machine speed: 350 m/min - Web width: 1000 / 1200 / 1300 mm - Printing cylinder circumference: 350 - 900 mm - Material diameter: 800 / 1000 mm - No. Color: 10 colors

2023 VietnamPlas On-site Tour | PRM-TAIWAN

VietnamPlas is an important exhibition in the plastic and rubber industry. Watch the on-site tour video from VietnamPlas for more information!

3000 Ton Plastic Injection Moulding Machine | CLF

3000 Ton Plastic Injection Moulding Machine - Chuan Lih Fa CLF's Products: ⚫Via continuous challenging high-end injection machinery, CLF has success- fully invented the multi-circuit plastic injection machines, horizontal injection molding Machine, servo-driven hydraulic fully closed-loop controlled injection machine, multi-color/multi- resin injection molding machine, and etc. ⚫With our strength of machinery diversity, we could provide our customers the scheme of installment of whole factory buildings to achieve perfection of techniques and produc- tion capacity, and finally help them save the cost and shorten the investment cycle.

MOLD TEMPERATURE CONTROLLER, YANN BANG

YANN BANG, Patented Mold Temperature Controller, Temperature Controlled Unit Our temperature control unit can use water/oil heating system to secure the high quality of plastic production made by injection, extrusion and blow molding machines. Learn more: https://www.yannbang.com/mold-tempera...

Core Objects for Plastic & Rubber Machines | NAN YUN

Do you know SCREWS and BARRELS? Those are dispensable parts to injection molding machines, extruders and relevant machines in the plastic and rubber industry. Nan Yun Industrial Co., LTD., an expert who specializes in designing and manufacturing a full range of screws and barrels. With more than 30 years of experience, Nan Yun’s team provides customization services to meet customer’s special applications. By interviewing Mr. Kuo-Feng Huang, Assistant Manager of ST Dept., we also discussed an important engineering technology concept “Reverse Engineering” and how Nan Yun applied it into their business. Moreover, after-sales service is one of Nan Yun’s values. By Gathering feedback and reviewing consultation forms in past years, they could provide accurate solutions to their customers. 【Video Outline】 00:00 - Introduction 00:45 - The role of Nan Yun 01:22 - The specialty of Nan Yun 03:03 - Service during the pandemic 03:37 - Solutions to customer’s problems 04:25 - Future plans and messages to customers 05:23 - Closing

Customization & After-sale Service | GENIUS

More and more countries request all plastic-made products to be fully recycled; therefore, plastic recycling machines have been important. Mr. Peter Tsai, the general manager of Genius, explained the best seller “Single Stage Cutter Compactor Plastic Recycling Machine” as known as KRIEGER series in their product lines. This machine is capable of recycling HDPE drums and films with superior features, such as Italian-made heater, extruder-degassing vents, dual piston filters. With excellent customer satisfaction and customization service, Genius awarded an order from a returning Japanese client again. According to the language and the use habits, the parts of the machine have been installed with many Japanese brands in order to lessen obstacles while Japanese employees operate the machine. Moreover, Peter has expressed how Genius values customer satisfaction, customization service and after-sales service in the interview. Through this video, you will be showcased how Genius is running the testing of Single Cutter Compactor Machine before shipment. 【Brief Intro】 Genius Machinery specializes in the comprehensive plant planning of plastic recycling equipment. With over 40 years of experience in designing and manufacturing plastic recycling equipment. 【Video Outline】 00:00 - Introduction 00:31 - Machine Testing & Superior Features 02:10 - Conveyor Belt 02:19 - Compactor 02:50 - Extruder-degassing 03:19 - Dual Piston Filter 03:40 - Pelletizer 04:18 - Details of customized control panel 05:21 - Materials Process & Applications of Machine 06:27 - After-sale service for installation & maintenance 08:05 - Messages to customers

Water Transfer Printing Film and Equipment Manufacturer | YUAN HENG TAI-

Semi Automatic Hydro Dipping Machine with Lay film, Auto Spray Activator, and Production Arm. A powerful combination of all necessary important processes for WTP processing. From the very beginning laying, and the following activator spraying to the final dipping stage, done the main WTP process with only one button. This machine includes dipping tank, auto film layer and auto spray system. The combination of these 3 components not only makes WTP even simple, but more important– stable quality to the final product. The system can memorize multiple sets of different processes. This dipping machine is perfect for large product and medium quantities of production/day.

High Speed Slitting Machine - S2A Series | YICHEEN

YICHEEN is a professional equipment supplier that specializes in soft-material cutting technology, including die cutting, sheet cutting, slitting and laminating. Since 1979 we have been supplying soft material cutting machinery. This has now transformed into state of the art high-precision customized cutting equipment, which meets worldwide standards and guidelines.