3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine | GEORDING

3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine - GEOR-DING MACHINERY CO., LTD.. We specialize in manufacturing of 3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine. The main businesses include: 3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine and planning of entire plant’s equipment. While the demand for output and quality in 3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine worldwide is increasing day by day, our determination for upholding the motto, "Quality is number one. Output comes second. Customer satisfaction. Perfect service”, will never shift. Under your support and encouragement, we will continue to provide quality 3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine products and services to higher standards.

Online Exhibition - PRM Theme Pavilion | PRM What to Say EP6

Online Exhibition - PRM Theme Pavilion | PRM What to Say EP6 Are you still seeking appropriate suppliers under the unstable circumstance of COVID-19? We heard your concerns and heartfelt wishes for attending an online exhibition! Through PRM Theme Pavilion, without traveling abroad, you will have many opportunities to connect with the world. Now, we are excited to announce an upcoming new event PRM Theme Pavilion, which will bring you to the new horizon. In this video, we are gonna present what you will see in this online exhibition. This time, we will focus on showcasing manufacturers who are specializing in the packaging industry. Let's take a look at the PRM What to Say episode 6, where we are evaluating and introducing the next PRM Theme Pavilion which focuses on the Packaging industry. In the video, you will learn more about not only what this event is about, but also the benefit of the event for global visitors, how the event is planned and concentrated on a specific focus with the selected machine manufacturers and machinery lines that a packaging business all need.

Business Tips of Choosing Plastic Recycling Machine | PRM What To Say EP17

Do you understand different kind of plastic recycling machines? Each type of plastic could be processed by certain type of machine. If you are still confused in choosing machines for your business, you must watch this video.

How 2025 U.S. Tariffs Will Reshape the Plastics Industry | PRM What To Say EP20

In this episode of PRM What To Say (EP20), we dive into the latest developments of the 2025 U.S. tariff policy and its profound impact on the plastics industry. What do the new 245% tariffs on China mean for global supply chains? How will Taiwan, Japan, Korea, and Europe be affected? Join us as we analyze the key changes, challenges, and future opportunities for plastics manufacturers worldwide. Topics Covered: U.S. reciprocal tariffs overview Strategic moves for manufacturers in 2025 Don't forget to subscribe for more insights on global trade, plastics machinery, and industry trends!

Food Packaging Solutions | AI SHIN Interview

At the recent TAIPEI PACK exhibition, PRM Media Channel had an interview with AI SHIN MACHINE CO., LTD. to discuss about the current situations in the packaging industry, upgrade in the service of the company due to current pandemic, also the machinery showcased. AI SHIN is famous for its Automatic Filling & Sealing Packing Machines. The company specialized in manufacturing high speed packing machines for food, filling and sealing liquid cups such as yogurt, juice and water cups. Let us know your opinion and the inquiry in the comment section. Stay tuned for the forthcoming interview videos and remember to subscribe to our social media channels for the similar videos!~ MAIN PRODUCTS/SERVICES OF AI SHIN: Automatic Filling Machine, Automatic Sealing Machine, Rotary Type Filling Machine, Filling & Sealing Machine, Bag Sealing Machines, Sealing & Packing Machines, Semi-automatic Sealer, Rotary Type Sealing Machine, Fully Automatic Box Filing & Sealing Machine for Butter, Capping Machine for Butter, Yogurt Packaging Machine, Pudding Filling & Sealing Machine, Frozen Food Filling & Sealing Machine, Cup/Bowl Instant Noodle Packing Machine, Packing Machinery, Cap Sealing Machine, Jam Cap Sealing Machine, Butter Filling/Sealing Machine, Cup Filling Sealing Machine ***

Air Bubble Film Extrusion Line - CHI CHANG

Air Bubble Film Extrusion Line - 2.5M Wide 3-layer Air Bubble Sheet Extrusion Line The 2.5M Wide, 3-layer Air Bubble Sheet Extrusion Line produced by Chi Chang Machinery Enterprise Co.,LTD has excellent quality and an outstanding reputation. The Air Bubble Film Extrusion Line includes Take-off unit & winder, In-line lamination, T-Die & laminating unit and EPS/EPE reclaim system.

High Speed 2 Lines Coreless Bag on Roll Trash Bag Making Machine | CHAO WEI

High Speed Fully Automatic 2 Lines Coreless Bag on Roll Trash Bag Making Machine | CHAO WEI, TAIWAN [DESCRIPTION of the Machine] ⚡️Special for two lines perforating coreless bottom and star sealing bags on roll. ⚡️In-line triangle folding device for star sealing bags. ⚡️E.P.C. (Edge Position Control) for the film at correct position. ⚡️Japan made servo motors & servo drivers control bag length precisely and high speed production, reducing electric consumption. ⚡️Bag length & production speed can be changed easily from touch screen. ⚡️German made photocell-SICK for accurate printing mark. ⚡️Automatic lift up reel unwinder with air shaft, reducing the number of employees. ⚡️Automatic tension control with AC motor and inverter system for jumbo diameter film roll. ⚡️Two lines automatic roll changing system.

Shrink Sleeve Conversion Seaming Machine - K5 Plus | WEBCONTROL

Machine Specification - WEBCONTROL Seaming Machine K5 Plus: -Machine Speed: 500 m/min -Width: 350 mm -Material Width: 720 mm -Unwind Diameter: 600 mm (Option 800 mm) -Rewind Diameter: 600 mm -Minimum Lay Flat Width: 40 mm with 18 mm option -Core Diameter: 3" (76 mm) -Lay Flat Tolerence: 0.25 mm The K5 PLUS combines all the advantages of the new PLUS technology with non-stop operation. The new PLUS series is the most advanced seamer in the industry. WEBCONTROL has once again innovated by launching the third generation of seamers which eliminates the forming tool. This new patented design makes the K5 PLUS the most operator friendly machine available, facilitating operator training with the most automated machine on the market. The K5 PLUS has 3 tension zones, which allows for a dedicated tension zone in the forming section for better layflat control. The unwind tension zone is now free to add innovations like laser integration for t-perforation or pin hole perforation while the film is flat. The K5 PLUS offers a long list of advantages that solve the issues that come with the previous generation of machines that use forming tools. This new machine promises to revolutionize the way shrink sleeves are converted. Make sure you see it before making any decisions.

2024 CHINAPLAS Interview | Shubham Extrusion

We were delighted to have CHINAPLAS at the ETERLONG booth and meet their largest buyer in India for an interview with us. Mr. Nirav Shah shared that 15 years ago, TAIPEIPas found their trusted partner through PRM-TAIWAN

Twin Screw PVC Pelletizing Line | TWIN SCREW

We are a pioneer of twin screw extruder. Description: TWIN SCREW EXTRUDER ⚫With two parallel counter-rotating screws for the palletizing. ⚫Reduction and torque-distribution unit with hardened, ground shafts and gear. ⚫Long service life for the processing units due to lower specific drive energy. ⚫Increased process reliability due to modern control technology. ⚫Easy maintenance and service. DIE FACE CUTTING ⚫Hinge flange type. ⚫High speed rotation of the knives. ⚫Continuous production of granulate. VIBRATION COOLER ⚫Up & Down two vibrating bed. SILO TANK ⚫Stainless steel. Our Service: Technology innovation, perfect service, and internationalization are always our core values, with this mission we have become the pioneer of twin screw extrusion in the global market and a reliable partner of our customers. TwinScrew will never stop progressing in the field of PVC extrusion and twin screw extrusion; we will no doubt lead the twin screw technology into an ultimate and great attainment.

Proportional Valves for Plastic & Rubber Industry | KAO LU

KAO LU ENTERPRISES CO. is an professional Taiwanese manufacturer. With experience for over 40 years, it’s one of the leaders of the proportional pressure and flow control valves. With high-quality manufacturing techniques, their distributors spread all around the world. 【Video Outline】 Company Introduction Product Application & Competitiveness Product Introduction Main Customers Application on Medical and Biotech Equipment Application on Plastic and Rubber Equipment Advantages of the Era of Industry 4.0 Contact Information

Sustainable Innovation of Blown Film Machine | KUNG HSING

The latest innovation of Three Layer Blown Film Machine is featured with 3 in 1 Gap Winder that combines Surface Type, Contact Drive Type and Gap Winding. We are pleased to invite Kung Hsing Machinery to share the insight of the Blow Film Industry with us, which includes application, ESG and the effect of geopolitic to the economy. 【Product Features】 ● Five layers co-extrusion blown film line ● Φ300 mm Die : Production output 600 kg / hr ● Gain in weight gravimetric dosing unit ( Italy made) ● Profile measurement & auto thickness control (Auto Air Ring-Height Adjustable, High Efficiency Cooling and High Output Rate, Germany made) ● IBC computer control system (U.S.A Made) ● Horizontal oscillating take-up unit ● 3 in 1 Gap winder ( Surface type, Contact Drive Type and Gap Winding) 【Video Outline】 0:00 Welcome to K 2022 0:24 Introduction of Kung Hsing Machinery 0:53 Highlights of Kung Hsing at K 2022 1:54 Applications of KS Blown Film Machines 2:34 Upgrade of Three Layer Blown Film Machine 5:38 Strategy and Implementation to ESG 6:51 Customer Oriented Service 7:54 Advantages of Taiwanese Supply Chain 8:54 Occurrences affect Global Market 10:04 Development Trends of KS Blown Film Machine 11:07 More information on PRM B2

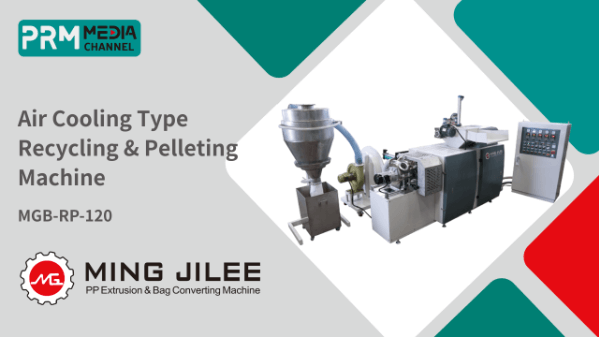

Air Cooling LD/HDPE Recycling Machine, MGB-RP-120 - MING JILEE

Air Cooling LD/HDPE Recycling machine is designs for re-pelletizing PE plastic waste material / t shirt bag die cut wasteThe material can be PE blown film waste, T shirt bag handle die cut waste, etc... Air Cooling Type Plastic Recycling Machine is equipped the power save, the SCR power regulator control. The real power consumption is around 15~20 kg. 1. Machine Specification: (1) Machine dimension a. Main machine : 2,770 (L) × 2,530 (W) × 2,060 (H) mm b. control box : 920 (L) × 420 (W) × 1,660 (H) mm (2) Machine weight : 2,430 kg (3) Power preparation : 45 kg (4) Power consumption : 20 kw 2. Machine Performance: (1) Applicable resin : LDPE / LLDPE / HDPE Waste Film (2) Output a. LD/LLD PE : 50 - 60 kg/hr b. HD/ PE : 40 - 50 kg/hr Air Cooling LD/HDPE Recycling Machine Features: (1) SCR power regular for saving power (2) Rotating die cutting head to get good quality of cutting shape (3) Less space required (4) Extra Cooling fan to cool down the PE material. Air Cooling Type Plastic Recycling Machine Further information: https://www.mingjilee.com/en/product/...

High Speed Zipper Strip Hot Lamination Side Sealing Machine | MING JILEE

【Machine Features】 Taiwan-made and stable PLC controller The size control of Zipper Bag Side Sealing Machine is by servo motor. Made in Japan. Zipper Bag Side Sealing Machine is equipped mark sensor for printed material. For getting the best quality of zipper bag product, unwinding station is mount the auto tension control. The individual zipper strip unwinder with motor control to get the high quality of zipper sealing quality. Ultrasonic welding is design by motor driven for highest speed production. The ultrasonic welding station to crack the zipper on the edge of the bag for easy side sealing cutting. 【Company Intro】 Ming Jilee Enterprise Co., Ltd. is manufacturing film blowing machinery with materials of PP and LD/HDPE; PP thin and thick sheet making machine; waste recycling and pelletizing machine, stationery making machinery- can produce business file/data bag/file clip/photo pocket/name card pocket/index/bubble paper envelope; sealing & cutting machinery-side sealing bag/t-shirt bag.

TPE, TPR, TPU Materials Explained | PRM What to Say EP12

In this episode, we will open a special page for TPU and TPE, TPR materials. Because there are several common confusions about them. Then, let’s understand the differences and fields of application of those innovative materials together. 【TPE/TPR】 Both TPE(Thermoplastic Elastomer) and TPR(Thermoplastic Rubber) belong to the family of Thermoplastic Elastomers, and there isn’t a defined industry standard to distinguish them. But, it is certain that TPE is made from SEBS, while TPR is made from SBS block copolymers. [TPE/TPR Applications] TPE/TPRs are great for anywhere that flexibility, comfort, or cost savings are needed. They are a top choice for medical applications like surgical and dental tubing and also tubing used in the food/beverage industry. 【TPU】 TPU(Thermoplastic polyurethane ) is a soft polyether type polyurethane that is available in a range of hardness grades, which gives a diverse application range to TPU. There are two main types based on soft segment chemistry: Polyester-based TPUs, and Polyether-based TPUs. [TPU Applications] With their resistance properties, TPU is superior for use anywhere that ozone, extreme temperatures, and high levels of abrasion are a concern. In addition to medical uses, TPU is also a popular material for sporting goods, tubing, wire, protective coatings, and more. All those materials above are alternatives for natural rubber and are easy to manufacture. Moreover, those materials can be 100% recycled.

Bag on Roll Making Machine | COSMO

COSMO has many years of experience in bag making machines. We are still willing to have much more improvement and all the consumers are satisfied with the quality of machines offered to you. 【Machine Features】 2 lines coreless star sealed bag on roll making machine Oscillation film feeding & sealing system for stability and high out put Automatically reel changing system High production efficiency to save manpower and time Servo motor, as standard attachment, makes it easy to adjust the bag length and the production speed Computer control over the entire process From film roll to final bag, non-stop, one process flow Automatically stop when running out of film/ film feeding blocks or bags jam/ color scanning misses 【Company Introduction】 COSMO Machinery Co., Ltd. established in March 2001, is well-known for Taiwan manufacturing plastic bag making machinery with servo driving systems. The product from COSMO has the servo motor as standard attachment, makes it easy to adjust the bag length and the production speed, computer control over the entire process, component self-testing function available, high production efficiency to save manpower and time. Up to now, COSMO products are extensively exported to 100 countries spreading all over the world.

2024 CHINAPLAS Interview | CHINAPLAS

We are here with Ms. Ada from the CHINAPLAS. She also shared very useful information about the forthcoming CHINAPLAS 2024 including the focus of the exhibition.

Upstream and Midstream of Taiwan Automation Manufacturing | What To Say EP16

Have you ever wondered why Taiwan is an automation and automotive parts manufacturing stronghold? In this episode, you will be explaining the first two streams, which are upstream and midstream, which are the initial points for the following procedure of the automotive industry.

Two Platen Plastic Injection Molding Machine | CLF

Two Platen Plastic Injection Molding Machine - Chuan Lih Fa CLF's Products: ⚫Via continuous challenging high-end injection machinery, CLF has success- fully invented the multi-circuit plastic injection machines, horizontal injection molding Machine, servo-driven hydraulic fully closed-loop controlled injection machine, multi-color/multi- resin injection molding machine, and etc. ⚫With our strength of machinery diversity, we could provide our customers the scheme of installment of whole factory buildings to achieve perfection of techniques and produc- tion capacity, and finally help them save the cost and shorten the investment cycle.

Full Electric Co-EBM with visi strip (4 head double station) | CM-90.55FVH2D | Chia Ming

CM-FE90.55FVH2D Full Electric Co-Extrusion Blow Molding Machine - Continue extrusion with horizontal movement and toggle clamping. Fully automatic and highly efficient production. -------------------------------------------------- Why Go Full-Electric? ► Energy savings 20%~70% ► Precise and more efficiency ► No hydraulic, less noise, no oil leakage ► Easy maintenance -------------------------------------------------- / Key Features / ★ All-electrics (Fully servo motor driven) ★ Servo Drive Die Head Nodding System ★ Full Electric Parison Control System ★ Crank Type Servo Drive Carriage Movement ★ Visi Strip function ★ Auto deflashing device ★ Backhoff, Germany and Keyence, Japan control system -------------------------------------------------- / Other Features / ★ Equipped with robot arm (2D Gripper) ★ Post cooling ★ Auto loading system ★ Residue conveyor to crusher ★ Built by standard components, i.e. Beckhoff, Festo, SMC, Toshiba, Tokimec, Schneider, ABB, Omron, ensuring straightforward maintenance at lower cost and global spare parts availability -------------------------------------------------- / Optional equipment or function/ ????Support the “Industrial” internet of things. (More info, please contact.) -------------------------------------------------- / Application/ Jerrycan/ Food packaging/ drinks/ detergents/ reagents/ cosmetics/ medicines/ engine oil bottles/ lubricants/ jars/ home products/ car parts/ decoration parts...

Exclusive Interview: Jawhari Kamil on the 20th Saudi PPPP and Vision 2030

Join host Jason as he sits down with Jawhari Kamil, chief organizer of the 20th Riyadh Expo, for an insider’s look at this landmark event. In just a few minutes you’ll learn: What makes the 20th Saudi PPPP and how it reflects Saudi Arabia’s rapid industrial momentum Kingdom Vision 2030 in action—why national transformation goals are shaping every corner of the show Sustainability in focus: from low-carbon solutions to green partnerships that matter A surprise reveal: Jawhari hints at a major collaboration with a world-famous exhibition coming in 2026—watch to the end to find out which one! Whether you work in plastics, packaging, or any sector eyeing the Middle East, this interview delivers fresh insights you won’t want to miss.

PRM線上展覽 - 包裝主題館 | PRM What to Say EP7

疫情下是否煩惱找不到國外買主呢? 我們聽到台灣塑橡膠廠商的心聲了! 透過本次PRM舉行的線上展覽 - 包裝主題館,讓你不用出國隔離,也能夠接觸到國外買主! 2021年PRM包裝主題館即將於9月到10月盛大舉行,本次將專精在包裝產業的,將為台灣廠商和國外買主帶來全新的體驗。本集影片將為各位解說包裝主題館所帶來的效益!

Core Objects for Plastic & Rubber Machines | NAN YUN

Do you know SCREWS and BARRELS? Those are dispensable parts to injection molding machines, extruders and relevant machines in the plastic and rubber industry. Nan Yun Industrial Co., LTD., an expert who specializes in designing and manufacturing a full range of screws and barrels. With more than 30 years of experience, Nan Yun’s team provides customization services to meet customer’s special applications. By interviewing Mr. Kuo-Feng Huang, Assistant Manager of ST Dept., we also discussed an important engineering technology concept “Reverse Engineering” and how Nan Yun applied it into their business. Moreover, after-sales service is one of Nan Yun’s values. By Gathering feedback and reviewing consultation forms in past years, they could provide accurate solutions to their customers. 【Video Outline】 00:00 - Introduction 00:45 - The role of Nan Yun 01:22 - The specialty of Nan Yun 03:03 - Service during the pandemic 03:37 - Solutions to customer’s problems 04:25 - Future plans and messages to customers 05:23 - Closing

HDPE Drum Plastic Recycling Machine ft. Chemical Drum Pelletizing System | GENIUS

Compacting & feeding The high speed compactor creates superior efficiency friction heat to compact the fluffy materials. Removed moisture during processed. Increase the highest throughputs for more productivity. Multiple Cooling Triple cooling sections – air cooling system, compactor body water cooling system and water spraying system. The operator can set the temperature of each to stably control the compactor's temperature. Better Flexibility Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients' needs presenting a smart and reliable plant. Cost Saving Energy cost saves up to 20%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant. 【Company Introduction】 Genius Machinery Co., Ltd. specializes in the comprehensive plant planning of plastic recycling equipment. With over 40 years of experience in designing and manufacturing plastic recycling equipments. Since its establishment, Genius Machinery Co., Ltd. has provided industries with plastic washing lines, plastic recycling machines, pelletizers, plastic squeeze dryers, crushers, shredders, and other complete series of manufacture line for one-stop services.

Flying Knife Cutting Bottom Sealing Bag Making Machine, MGA-BSF-1000W | MING JILEE

Flying Knife Cutting Bottom Sealing Bag Making Machine, MGA-BSF-1000W For Further information:https://www.mingjilee.com/en/product/Wire-Impulse-Bottom-Bag-Sealing-Machine-with-Flying-Knife-Cutter.html

傳感器 & 聚合物測驗設備 | Dynisco

PRM-TAIWAN曾在2019的K採訪過Dynisco全球副總裁Bill Desrosiers,歷經了三年全球環境大轉變後,我們很榮幸再與Bill見面。 Bill向我們講述這三年來產業間的轉變,以及K三大主題的應用。另外提及Dynisco在今年參展的首要任務,是要和全球的夥伴們分享最新的技術發展以及如何應用於循環經濟

How Machines Shape Every Shot: The Engineering of a Golf Ball

Every perfect shot starts with precision engineering. In this video, we take you inside the manufacturing journey of a golf ball — from the resilient rubber core to the durable plastic outer shell. Watch how advanced molding machines, material processing systems, and pad printing technology come together to shape every ball with accuracy and consistency. You'll see how multi-layer construction enhances performance, how dimples help stabilize flight, and how automation ensures uniformity from core to cover. Whether it's molding, printing, or aerodynamic design, every detail is crafted by machines built for precision. This is the engineering behind every swing. This is how machines shape every shot. Powered by Taiwan's leading machinery manufacturers, and brought to you by PRM-Taiwan — your trusted platform for discovering top suppliers and cutting-edge plastic & rubber processing solutions.

Escalation of Industry 4.0 in Plastic Machine Industry | PRM What to Say EP8

Escalation of Industry 4.0 in Plastic Machine Industry | PRM What to Say EP8 Nowadays, everything has been advanced to automation and connection to the Internet. Even in the Plastic and Rubber Industry, which we might consider as the traditional industry, it has been upgraded gradually through the industry 4.0 revolution. Let’s take a quick look to understand what are Industry 4.0 and IoT, and how does the Plastic and Rubber Industry apply it. Know PRM Media Channel more on: PRM YouTube: https://www.youtube.com/c/PRMTaiwan PRM Facebook: https://www.facebook.com/PRMMediaChannel PRM LinkedIn: https://www.linkedin.com/company/prm-taiwan/

Rotary Table Injection Molding Machine | TAIWAN KINKI

MACHINERY IN THE VIDEO: Rotary Table Injection Molding Machine with Full Auto System from TAIWAN KINKI (TKC) [TAIWAN KINKI LINES OF BUSINESS] Production of vertical plastic injection molding machines. Design of automatic injection molding machinery. Turn-key plants for accessories and peripherals for injection machinery. Injection mold design and manufacturing. Electrodeposition, powder coating, baking enamel, and leather treatment. Agency of the vertical injection machine and Zinc alloy coating. [APPLICATIONS] Especially suitable to manufacture Automobile Parts [TAIWAN KINKI (TKC) BACKGROUND] TKC had over 40 years of experience in Vertical Injection Molding Machine manufacturing. The company offers a full series of vertical injection molding machine portfolios including Standard, Slide, and Rotary table models. TKC also offers mold design and a full auto system for customer's products.

JIT-SS |JIT T-Shirt Bag Making Line- |JANDI'S

Blown Film→Printing→Bag Making→Die-Cut Recovery, from resin to finished bags, ALL IN ONE PROCESS. HDPE / LDPE / Biodegradable / Compostable Material AVAILABLE

The Best Choice of Bag Making Machines | COSMO

COSMO has many years of experience in bag making machines. We are still willing to have much more improvement and all the consumers are satisfied with the quality of machines offered to you. 【Product Lines】 T-shirt Bag On Roll Making Machine Bag On Roll Making Machine T-shirt Bag Making Machine Garbage Bag & Industrial Bag Making Machine T-shirt & Bottom Sealing Bag Making Machine Side Sealing Bag Making Machine Air Cushion Bag Making Machine Stretch Rewinder Glove Making Machine 【Company Introduction】 COSMO Machinery Co., Ltd. established in March 2001, is well-known for Taiwan manufacturing plastic bag making machinery with servo driving systems. The product from COSMO has the servo motor as standard attachment, makes it easy to adjust the bag length and the production speed, computer control over the entire process, component self-testing function available, high production efficiency to save manpower and time. Up to now, COSMO products are extensively exported to 100 countries spreading all over the world.

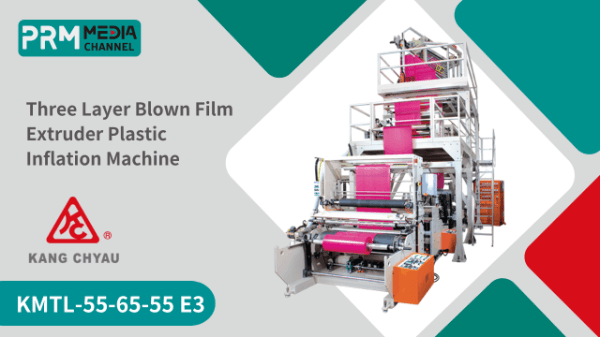

Three Layer Blown Film Extruder Plastic Inflation Machine | KANG CHYAU

Introducing three-layer blown film extruder machine, in another name called three-layer plastic film inflation machine. From one of the pioneering blown film extruder manufacturers in Taiwan, KANG CHYAU. For more information and/or inquiry, please directly contact the manufacturer at the contact button. For any assistance, PRM will be more than happy to assist, please use CONTACT PRM button to leave a comment below. Then we will reply and contact you asap. Machinery in the video: THREE LAYER BLOWN FILM EXTRUDER PLASTIC INFLATION MACHINE | Model No: KMTL-55-65-55 E3 Film Width: 500-1800 mm Screw Diameter: Ø 40-45-40/45-55-45/55-56-55 mm Suitable Materials: HDPE/LDPE/LLDPE/mLDPE

6 Colors High Speed Flexo Stack Printing Machine PKF-1000-6 | PRINTPLAS

6 Colors High Speed Stack Flexo Printing Machine PKF-1000-6 | PRINTPLAS The Central Impression drum surface is precisely grinded and coated, without risk of pores and with the dual wall design for water cooling purpose to ensure material to be smoothly transported and precisely printed. Machine framed with 80MM cast metal plate, provide a very steady, vibration free foundation for the printing work. High sensitive feed in and feed out tension controlling system, incorporated with synchronized motion control to ensure constant tension during printing. Super fine printing adjustment device to secure printing accuracy at each printing station. Long arch drying tunnel with strong blower to ensure drying of ink during high speed operation. Machine controlled by Japan PLC system with full color user friendly HMI. Full servo system with PLC memory module auto printing controlling system can be added to achieve a high level automation. Quick change over sleeve system can be adopted as optional.

Rubber & Silicon lnjection Molding Machines | LONG CHANG

Long Chang is manufacturing the series of Rubber & Silicon injection Molding Machines, and Heated Compression Molding Machines etc. 【Machine Series】 Silicone Injection Molding Machine Rubber Injection Molding Machine Horizontal Automatic Rubber & Silicone Injection Molding Machine Single Body / Twin Body Vacuum Oil Hydraulic Compression Molding Machine Vacuum Rubber Oil Seal Hydraulic Compression Molding Machine Single Body / Twin Body Die-Moving & Ejection Compression Molding Machine Four Columns Type Oil Hydraulic Press EVA Foam Tire / Single Body Double Color Of Automatic Oil Hydraulic Compression Molding Machine 【Company Introduction】 Long Chang Mechanical lndustrial Co., Ltd. was established in 1971, under the leadership of president Huang Chin-Huo with the idea of "always be loyal to the obligation, give more than enough thought to operate the business" and demands "making the perfection more perfect" to be the target.

Quick Mold Change System | FORWELL

Forwell has been a pioneer of Quick Mold Change Systems for many years. With over 20 years of experience in developing these systems they can offer you the best for your molding operations. These fully customizable Quick Mold Change Systems drastically minimize setup times, maximize efficiency and increase safety. Forwell’s Quick Mold Change System can be designed to fit almost any injection molding machine and mold casting machine to allow for quicker mold change times, resulting in shorter machine down time and increased productivity. This system uses a special mold clamp that does not require a cut out on the mold, increasing its application versatility and allowing it to be used with a large number of different molds.

PRM Media Channel at TAIPEI PACK 2020

TAIPEI PACK once again is held in December 2020 at Taipei City, Nangang Exhibition Hall 1. PRM Media Channel was on the field to share insight into the packaging industry. In 2020 many large exhibitions in the world have been forced to cancel/postpone due to the global pandemic. Thanks to Taiwan's relatively safer environment, TAIPEI PACK successfully launched as a combination of six different Exhibitions in one. There are more than 900 domestic and international exhibitors on-site waiting to meet the visitors. Moreover, there are many online on-site exhibitions and conferences scheduled for the interest of global visitors. During the exhibition, PRM Media Channel conducted interviews with the exhibitor to gather insights into the industry. Stay tuned for the forthcoming interview videos and remember to subscribe to PRM Media Channel!~

Solventless Lamination Machine-LMC-SF1300 | WEBCONTROL

Solventless Laminating-Solventlless Laminator-LMC-SF1300| WEBCONTROL Webcontrol Machinery Corp has been specializing in manufacture of Solventless Laminating since 1988. Webcontrol ceaselessly develop new machine to extend production line for meeting various needs of customers. In additions, we constantly improve our Solventless Laminating with new technology, and innovate to enhances its performance, efficiency and reducing waste on production. Our consistently aim is to build high-performance, sophisticated Converting Machinery with inexpensive price as well as providing fast Solventless Laminating service ensure our worldwide customers must be satisfied.

TaipeiPLAS 2022 Live | PRM x KAOLU x PIDC

The self-media era is coming! The plastics & rubber industry not only allows specific people or professionals to learn about this area. Throughout PRM's interview videos, we convey general information from plastics & rubber industry, environmental issues and social enterprise responsibility topics. ⏰ 9/30(Fri.) 15:00 (GMT+8) 【KaoLu Enterprise】 Kao Lu Enterprises Co. Ltd., established in 1980, has been dedicated to manufacturing and supplying premium quality pneumatic components such as valves, cylinders, and ancillary accessories. 【Plastics Industry Development Center | PIDC】 What's the key role that PIDC plays in Taiwan society and how they provide services to plastics manufacturers. By interviewing General Manager of Dr. Hsiao, he would share the insight of SDGs, 2050 Net Zero programme, and also provide advice to Taiwanese enterprises.

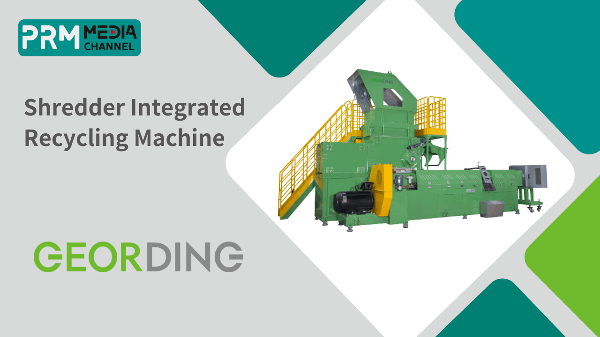

Shredder Integrated Recycling Machine | GEOR-DING-

Shredder Integrated recycling machine Features: -Can handle large heavy materials or thin-film materials 0:50 -Automatic backfllush screen changer,Reduce the screen changing labor cost 1:03 -Side Feeding Twin Screw design

2024 InterPlas Thailand Interview | SHINI

In this video, we have the pleasure of interviewing Siwakorn Tachapanich (Bank), the Sales Executive of Shini's local agent in Thailand. Shini boasts an exceptional sales and engineering team in Thailand, always ready to provide top-notch service whenever needed. Watch as we delve into their operations, commitment to customer satisfaction, and the unique advantages they bring to the market.

High Speed Zipper Bag Making Machine With In-Line Zipper Lamination | MGA-06Z-800D

High Speed Zipper Strip Hot Lamination Side Sealing Machine, MGA-06Z-800D Zipper bag side sealing machine is latest design to produce zipper bag / Ziploc bag / IKEA zipper bag/ grape bag/ slider zipper bag. The zipper bag side sealing machine is equipped 3 sets of servo motors to control the best tension and high speed production. The zipper bag side sealing machine is equipped in-line zipper strip sealing station. MACHINE PERFORMANCE (1) Feed material : LDPE, HDPE, PP, EVA (2) Single layer film thickness a. Side sealing bag : 0.02 - 0.08 mm b. zipper bag : 0.04 - 0.08 mm (3) Effective bag width (feeding length) : 85 - 600 mm (4) Effective bag length (sealing width) : 150 - 650 mm (5) Output : 40 - 200 pcs /min (depend on size and thickness) FEATURES (1) The PLC controller is made in Taiwan and very stable. (2) The size control of Zipper Bag Side Sealing Machine is by servo motor. Made in Japan (3) Zipper Bag Side Sealing Machine is equipped mark sensor for printed material (4) For getting the best quality of zipper bag product, unwinding station is mount the auto tension control (5) The individual zipper strip unwinder with motor control to get the high quality of zipper sealing quality. (6) Ultrasonic welding is design by motor driven for highest speed production (7) The ultrasonic welding station to crack the zipper on the edge of the bag for easy side sealing cutting. (8) the best design of zipper bag side sealing machine, made in Taiwan

CHINAPLAS 2021 Organizer Interview | PRM Media Channel

Recently despite many exhibitions that have been canceled or postponed, CHINAPLAS 2021 successfully made the event to be held on time, April 13th to 16th, 2021. In this manner, PRM Media Channel has conducted an online interview with Ms. Ada Leung, the General Manager of Adsale Exhibition Services Ltd., the organizer of CHINAPLAS. Ms. Ada Leung sincerely replied to our questions about this special event at a special time due to the pandemic. She also shared very useful information about the forthcoming CHINAPLAS 2021 including the focus of the exhibition, online activities for the visitors who cannot attend the exhibition, future plan of CHINAPLAS through digitalization and hybrid exhibition model. Let's take a look at the interview video to learn more, and let us know your opinions and questions.

Recycling Solutions for Packaging Industry | POLYSTAR Interview

At the recent TAIPEI PACK 2020, the famous packaging machinery exhibition of Taiwan, we have interviewed Ms. June Pei, from POLYSTAR. POLYSTAR is one of the most famous and leading recycling and blown film machines manufacturer from Taiwan, and has sold machinery in many countries around the globe. Ms. Pei shared her opinions and observations about the packaging industry, their recycling solutions related to the packaging industry, and also introduced the machinery they are showcasing at the exhibition. Moreover, she also mentioned the implementations to ease the effects of the pandemic on the business and the solutions they provide to their current and potential customers. Let's watch the interview video together and learn more. Thank you for your opinions and questions that you can leave as a comment. Remember to subscribe to our social media channels for the forthcoming interview videos and similar videos!~

Blown Film Machine HDPE LDPE LLDPE (ABA) Two Layer | KANG CHYAU

Introducing Blown Film Machine from one of the pioneering blown film extruder manufacturers in Taiwan, KANG CHYAU. For more information and/or inquiry, please directly contact the manufacturer at the link given above. For any assistance, PRM will be more than happy to assist, please just leave a comment below. Then we will reply and contact you asap. Machinery in the Video: HDPE LDPE LLDPE (ABA) Two Layer Blown Film Machine from KANG CHYAU MODEL: KMTL-50S SUITABLE MATERIAL: HDPE / LDPE / LLDPE APPLICATIONS: Car Film, Food Packaging, Courier Bag, and so on. FILM THICKNESS: 0.010-0.15 mm FILM WIDTH RANGE: 1200 mm FILM OUTPUT: 90-140 kgs/hr

TPE, TPR, TPU Materials Explained | PRM What to Say EP12

In this episode, we will open a special page for TPU and TPE, TPR materials. Because there are several common confusions about them. Then, let’s understand the differences and fields of application of those innovative materials together. 【TPE/TPR】 Both TPE(Thermoplastic Elastomer) and TPR(Thermoplastic Rubber) belong to the family of Thermoplastic Elastomers, and there isn’t a defined industry standard to distinguish them. But, it is certain that TPE is made from SEBS, while TPR is made from SBS block copolymers. [TPE/TPR Applications] TPE/TPRs are great for anywhere that flexibility, comfort, or cost savings are needed. They are a top choice for medical applications like surgical and dental tubing and also tubing used in the food/beverage industry. 【TPU】 TPU(Thermoplastic polyurethane ) is a soft polyether type polyurethane that is available in a range of hardness grades, which gives a diverse application range to TPU. There are two main types based on soft segment chemistry: Polyester-based TPUs, and Polyether-based TPUs. [TPU Applications] With their resistance properties, TPU is superior for use anywhere that ozone, extreme temperatures, and high levels of abrasion are a concern. In addition to medical uses, TPU is also a popular material for sporting goods, tubing, wire, protective coatings, and more. All those materials above are alternatives for natural rubber and are easy to manufacture. Moreover, those materials can be 100% recycled.

Injection Molding Machine | CLF

Injection Molding Machine - Chuan Lih Fa Specializes in injection molding machine, CHUAN LIH FA MACHINERY WORKS CO., LTD. was founded in 1966, backed up with 40 years manufacturing injection molding machine, multi color injection molding machine, All electric molding machine, plastic injection molding machine, plastic injection mold, injection molding machine manufacturer experience. CLF Supply maximum injection machine machine all over the world. Precisely productive equipments and rigidly productive procedures have providing customers with satisfied multi color injection molding machine, All electric molding machine, plastic injection molding machine, plastic injection mold, injection molding machine manufacturer quality to help them getting most profit.

GOLD GREAT GOOD MACHINERY | PRM Media Channel Interviews at TAIPEI PACK 2020

At the recent packaging machinery exhibition, TAIPEI PACK 2020, we have interviewed Rita from GOLD GREAT GOOD MACHINERY. Rita shared her opinions and observations about the packaging industry, their implementations to ease the effects of the pandemic on the business, what kind of changes they made to sustain customer service efficiently for the PRM Media Channel audience. Moreover, Rita also introduces the machinery portfolio they have in the video. Let's take a look and share your opinions with us!~