尼龍 66 工程塑膠 - NBE7200G20

產品分類 : PA樹脂/尼龍

20%玻璃纖維增強 (黑色-超韌耐衝擊) 應用說明:手工具、電動工具、園藝工具用,汽車、機車、腳踏車零組件用,運動器材零組件用,電子、電器外殼及零組件用,O.A.辦公室零組件用,水資材用,醫療復健器材。

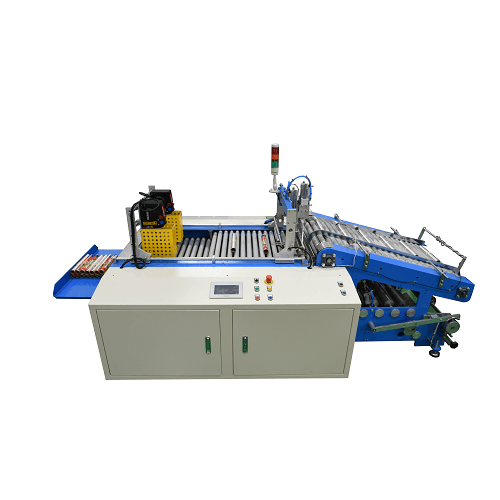

後段外包裝設備 - 裝盒機 - CSC-50A

產品分類 : 裝盒機

此折盒設備採用直立式自動生產方式.適用於多樣少量的產品.目前適用於軟膏,圓形與方形瓶之自動裝盒.於限定紙盒範圍內,只需更換相對應模具與零件位置調整,即可完成不同產品之生產。

三層共擠FFS重包裝吹膜機

產品分類 : 吹膜押出機

Heavy-duty bags are moisture-proof, high stiffness, impact resistance and puncture resistance. They are used to pack for various heavy-duty goods as like fertilizer, plastic material, grainy, granular and powder-type bulk goods with the form-fill-seal (FFS) machines. The usage of the heavy-duty bags are more and more popular in the market. Specification of KING-PLUS FFS Heavy-duty Sack Blown Film Machine Layers: 1 / 3 / 5 layers Distribution ratio: 1:2:1, 1:3:1, 1:1:2:1:1, 1:2:4:2:1 and so on. FFS film width: Most in 450 ~ 750 mm FFS film thickness: 0.1 ~ 0.18 mm Output: 300~420 kg/hr Option: Online Printer and Internal Embossing Device Achieve one-stop production line - form, print and embossing. - Four-color flexographic printing machine, printing possibility in 4+0, 2+2, 3+1. - Six-color flexographic printing machine, printing possibility in 6+0, 5+1, 4+2, 3+3. Internal embossing device - Raised patterns produced from the inside of bubble to make the surface rough that can enhance the friction to improve the security in piling the sacks.

非加壓型捏合押出機 (DAKE-系列)

產品分類 : 捏合機

此機器有「多種不同形狀的攪拌軸葉片設計」以及「排料方式」,廣泛應用於各種產業上的中、高黏度之原物料混練攪拌,如黏著劑、熱熔膠、矽膠、BMC、陶瓷、玻璃纖維、磁性複合物、印刷油墨、膠帶、熱固性樹脂、食品、化妝品、製藥工業等等。

DLM / WLM (乾式/ 濕式貼合)

產品分類 : 工業覆膜/塗佈機

DLM / WLM (乾式/ 濕式貼合) 乾式貼合於各種貼合技術中,是應用最普遍的一種貼合技術。其適合用於多種基材如薄膜貼薄膜、薄膜貼鋁箔、薄膜貼紙張之貼合。其優點為應用範圍廣,抗化學介質侵蝕性能優異,並用於內容物條件較苛刻的包裝。使用方便靈活,操作簡單,適用於多品種、批量少的生產。若您正在尋求一台泛用型的乾式貼合機,您可參考此類型貼合機。 濕式貼合特點是操作簡單,貼合劑用量少,成本低,貼合速度快且廣泛用於紙貼纖維、紙貼紙、紙貼紙板、紙貼鋁箔等材料的複合。若您正在尋求一台高效率、低成本紙類產品使用的濕式貼合機,您可參考此貼合機。

INSERT INJECTION MOLD

產品分類 : 射出模具

INSERT MOLDING TECHNOLOGY: When a metal, plastic or ceramic part needs to be embedded in plastic to improve product structure it is called Insert Molding. It is a widely used process and one that YOMURA TECHNOLOGIES specializes in. With Insert Molding, a part is placed in a mold cavity then a selected plastic material is injected directly over it resulting is a single part with the insert(s) encapsulated by the material. This process normally uses engineering plastics for improved wear resistance, tensile strength and weight reduction. Insert Molding can be a highly efficient alternative to the assembly of discrete parts using soldering, connectors, fasteners, or adhesives. It also expands plastic capabilities and can reduce final product cost by limiting the amount of costly metal needed to create a part. And importantly, because we can use conventional single shot injection machines for Insert Molding, tooling costs are lower than with a multi-shot processing. Benefits: Reduced assembly and labor costs Because insert molding joins numerous components with thermoplastic, assembly and labor costs are greatly minimized. For example, a single stamping can be overmolded, then perforated to create multiple circuit paths. Reduced size and weight By eliminating fasteners and connectors, and by combining the physical strength of resin and metal inserts, insert molding yields smaller and lighter components. Increased reliability With every part tightly secured in thermoplastic, an insert molded component prevents part loosening, misalignment, improper terminations, and other problems. The thermoplastic resin also provides improved resistance to shock and vibration. Increased design flexibility Designers appreciate the virtually unlimited configurations that insert molding allows. For example, in creating a 3D circuit board, overmolding permits circuitry to move freely through the part, from inside to outside, up walls, down in holes-and the plastic ties it all together. Materials: Engineering plastic or Thermo Plastic Rubber (TPR) inserted with metal frame die casting, plated copper pin, sockets, wire frames, etc. Applications: TPR + Metal Frame(3C Mechanical Parts) ABS + Al. Die Cast (Sports/ Medical) Eng. Plastic + Patting Pin/Eng. Plastic + Wireframe (Connector) Eng. Plastic + Copper Pin/Contact (Precision Electronic Component)

AUTOMATIC SHRINK FILM PACKAGING MACHINE (TPG 50)

產品分類 : 分切機和複捲機

Model TPG50, the automatic shrink film packaging machine. A special design for wrap roll products. It can be connected to the back side of rewinding machine as an automatic production line. You can not only make your product refined and protected, but also arrange manpower more effectively. TPG50 is carried 3 conveyors as 3 work areas. It uses conveyors to deliver products to the processing area. You can choose automatic feeding of the material,or feed by detected sensor. As shrinkable films, BOPP, PVC and PE can be used on TPG50. The length of over wrapping film can be set manually or detected by the mark sensor. For packing decoration, you can use printed film; or, equip with a label paper device. The device will insert a piece of label before shrinking. The label will be wrapped inside the film, makes your product eye-catching. The last step, electrostatic device and thermal-wind will perfectly pack your products! Welcome to consult machine with us, we will at your service.