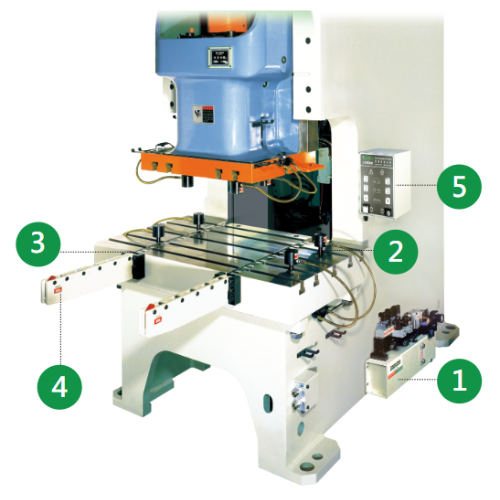

LIM、LSR立式矽膠機(轉盤/滑模)

產品分類 : 矽膠射出成型機

● Precision vertical clamping system (parallelism/ flatness : 0.02/100mm) , heavy-duty tie-bars, and low-pressure mold clamping work together to greatly extend machine & mold life. ● Increased productivity and efficiency with shuttle table or rotary table configuration. Pick and place products while another product finsihes molding.

HDPE 吹出級 / 黑色

產品分類 : HDPE樹脂

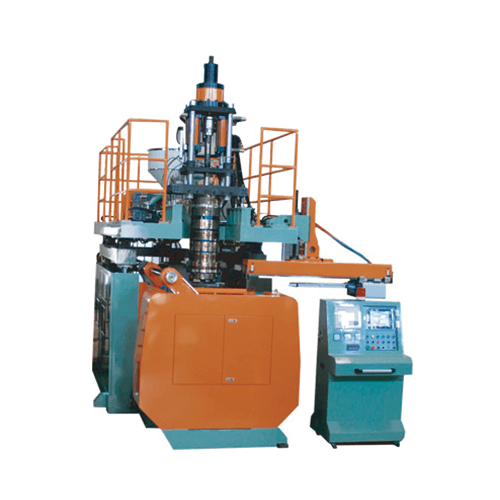

全自動押出中空吹氣成型機-I 系列

產品分類 : 全自動中空成型機

Full Shine的I系列吹塑機適用於生產各種塑料產品,例如工具箱,儲水箱,啤酒桶,油罐和汽車零部件。這些機器配備有蓄能器型模頭和多點型坯控制器。這些機器帶有橫向拉出機構。機架和模頭可移動,便於更換模具。

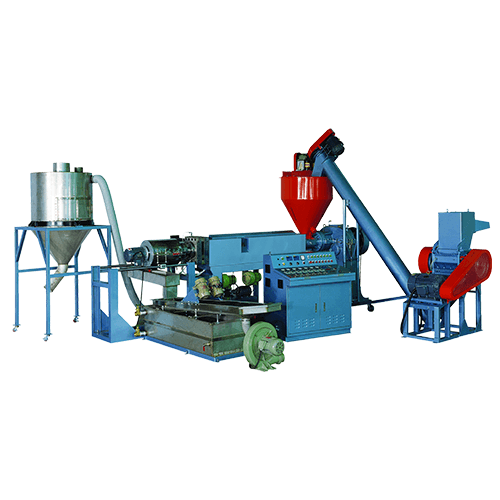

環保型雙機直結模頭切膠粒製造機(水冷式)

產品分類 : 製粒機

• 型號: TY-LBW 系列 • 產地: 台灣 • 適用樹脂: PP,PE,ABS,PS,HIPS. • 特殊使用樹脂: POM,PC,ACRYLIC • 產能: 100~800 kg/小時

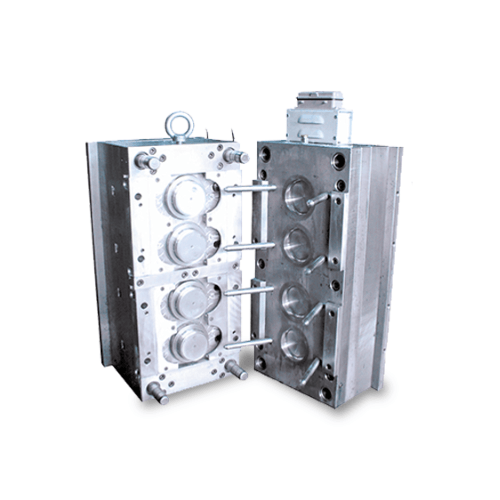

INSERT INJECTION MOLD

產品分類 : 射出模具

INSERT MOLDING TECHNOLOGY: When a metal, plastic or ceramic part needs to be embedded in plastic to improve product structure it is called Insert Molding. It is a widely used process and one that YOMURA TECHNOLOGIES specializes in. With Insert Molding, a part is placed in a mold cavity then a selected plastic material is injected directly over it resulting is a single part with the insert(s) encapsulated by the material. This process normally uses engineering plastics for improved wear resistance, tensile strength and weight reduction. Insert Molding can be a highly efficient alternative to the assembly of discrete parts using soldering, connectors, fasteners, or adhesives. It also expands plastic capabilities and can reduce final product cost by limiting the amount of costly metal needed to create a part. And importantly, because we can use conventional single shot injection machines for Insert Molding, tooling costs are lower than with a multi-shot processing. Benefits: Reduced assembly and labor costs Because insert molding joins numerous components with thermoplastic, assembly and labor costs are greatly minimized. For example, a single stamping can be overmolded, then perforated to create multiple circuit paths. Reduced size and weight By eliminating fasteners and connectors, and by combining the physical strength of resin and metal inserts, insert molding yields smaller and lighter components. Increased reliability With every part tightly secured in thermoplastic, an insert molded component prevents part loosening, misalignment, improper terminations, and other problems. The thermoplastic resin also provides improved resistance to shock and vibration. Increased design flexibility Designers appreciate the virtually unlimited configurations that insert molding allows. For example, in creating a 3D circuit board, overmolding permits circuitry to move freely through the part, from inside to outside, up walls, down in holes-and the plastic ties it all together. Materials: Engineering plastic or Thermo Plastic Rubber (TPR) inserted with metal frame die casting, plated copper pin, sockets, wire frames, etc. Applications: TPR + Metal Frame(3C Mechanical Parts) ABS + Al. Die Cast (Sports/ Medical) Eng. Plastic + Patting Pin/Eng. Plastic + Wireframe (Connector) Eng. Plastic + Copper Pin/Contact (Precision Electronic Component)

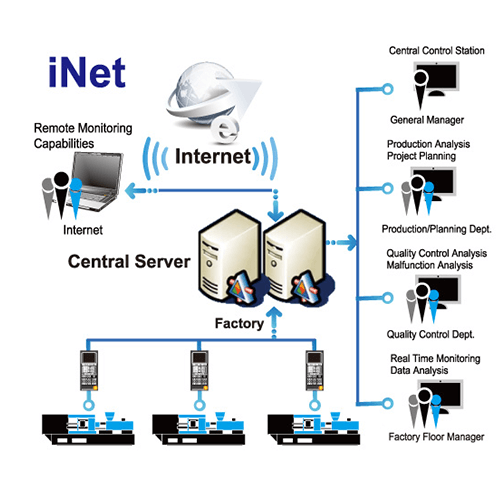

軟件產品及服務系統-iNET

產品分類 : 控制設備

iNet是一套完整的射出機工廠網絡化管理解決方案,協助塑膠廠生產與車間管理,藉由網路連結,作為管理層與生産現場溝通的橋樑;亦使管理者(administrator)進行全球營運,提供客戶管理新趨勢、掌控世界潮流,是成功邁向企業資訊化的必備武器。

橫走型機械臂TEH系列

產品分類 : 工業機器人

尼龍 6 工程塑膠 - NA1100G45

產品分類 : PA樹脂/尼龍

Glass fiber 45% reinforced, high flow. Applications: Hand tools, Power tools, Gardening tools, Automobiles, motorbikes, bicycle parts and components, Spare parts of sports equipment, Electronics, Electrical cases and components, OA office components, Water supplies, Medical rehabilitation equipment.

射出吹氣成型機 PK-IBT 系列

產品分類 : 射出中空成型機

全自動高速T卹製袋機-DP-HEP-HEEP-SERVO-系列

產品分類 : 塑膠袋製袋機

●帶傳感器控制的雙進料裝置(僅限DP-HEP-201)●帶光電池用於印刷登記●熱切割和密封裝置,帶有下熱●雙雙熱插裝裝置

PE材質專用熱轉印膜

產品分類 : 薄膜

各種PE塑料製品都可以使用熱轉印,一些複合材料如HDPE和LDPE,也可以使用,只要表面光滑平整,圖案和產品就可以完美結合。熱轉印膜有許多直接印刷所沒有的功能。 使用熱轉印膜和熱轉印機將優雅的設計轉移到產品上,使產品成為高價值的商品。 它可以提高質量,降低成本,增加利潤。

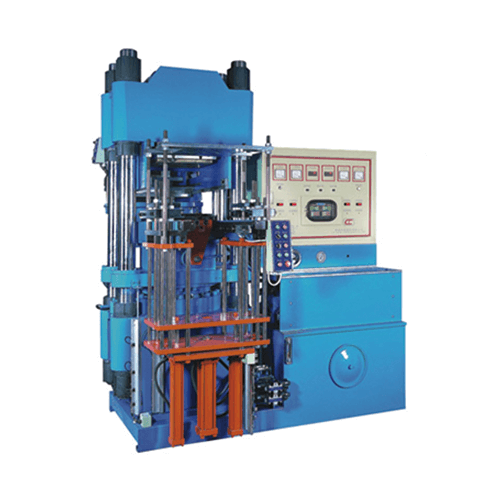

3RT開模橡矽膠連續轉射成型機TCC-500S3

產品分類 : 壓縮成型機

橡膠射出機 : 天然橡膠 合骨架橡膠 耐油橡膠 橡膠混合膠 合成橡膠 醫療用橡膠 耐熱橡膠 矽膠射出機: 固態矽膠