近期更新 立即訂閱

Scientific Molding Thinking: Molding is a Science not an Art

Injection molding is the process of converting plastic materials into flowable molten plastic materials by an injection molding machine, and injecting them into a mold cavity where they are cooled and solidified to form the final product. Plastic materials are less expensive to obtain compared with other materials such as metal, wood, and ceramics. In addition, it is easy to produce complex geometric products in large quantities with plastic materials, so people constantly extend the application of plastic products to various types of products. However, the complex flow behavior of plastics due to their viscoelastic property has led to many specious and erroneous experiences in injection molding, which may easily mislead the direction of problem solving.

FCS Innovative Model GENTREX - Master the Code for the Path to Net Zero Emissions

Global warming and climate change have made net-zero carbon emissions a global and common issue. Faced with high carbon emissions, companies propose that ESG should clarify the net zero trajectory and action path to achieve the set goals. Driven by this wave, many equipment, process and material manufacturers are making active efforts in response to the new opportunities brought by this transformation. Manufacturers need to achieve consumer preferences for product appearance refinement and shape, meet environmental protection and safety standards for materials, and consider energy saving, clean, high yield, easy recovery and other conditions and input costs in the production process, so they are faced with multiple challenges.

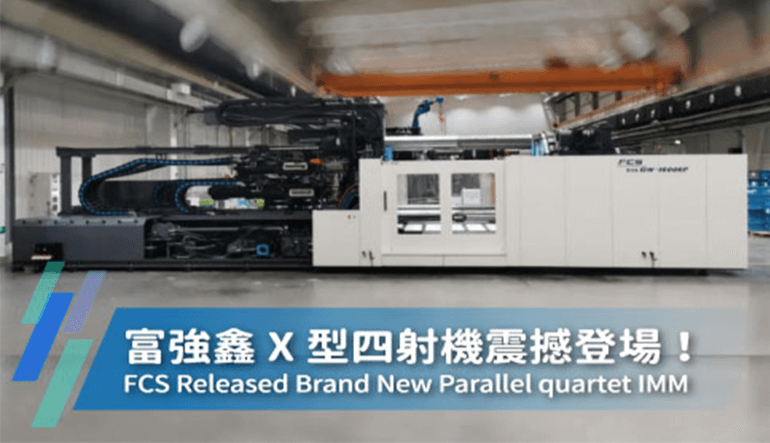

富強鑫多組分射出產品線再添新成員:X型四射機,震撼登場!

富強鑫多組分成型技術解決方案,增加全新成員:「X型四射機」。該項技術已成功導入富強鑫大型多組分射出機產品線。首台GW-1600R大型二板式多組分射出機(四射機),已順利交付中國知名大型車燈供應商,投入量產。

孟加拉塑膠市場需求強勁,FCS客戶穩坐家居用品龍頭品牌

隨著全球都市化/城市化的進步及經濟發展,家居用品作為民生消費品的一種,需求逐年增長,市場漸趨成熟、飽和。但在某些開發中國家,這些基本的民生用品才剛進入成長期。

既減重又增強的雙贏工藝–微發泡射出成型

隨著塑膠射出成型設備已臻成熟,唯有不斷優化製程才能延續市場競爭力。微發泡射出成型工藝(MuCell)可被用以降低塑件重量、縮短成型週期、提升耐衝擊強度,或延長產品壽命等,富強鑫(FCS)為您解析MuCell日益受到重視的要因及相關應用,替汽機車部件、家用五金、包裝容器等不同產品特性打造最佳成型方案。