近期更新 立即訂閱

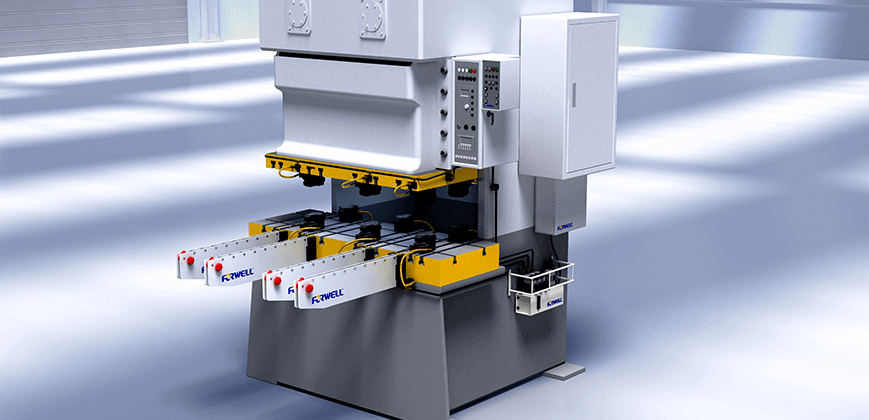

快速換模 101:概述、購買技巧、案例研究

快速換模系統 (QMCS) 是一種快速有效的方法,可以在很短的時間內從生產中使用的一個模具切換到另一個模具。花一分鐘了解選擇成功的快速換模系統的 3 個步驟,以及它如何幫助您實現使注塑線完全自動化的目標。

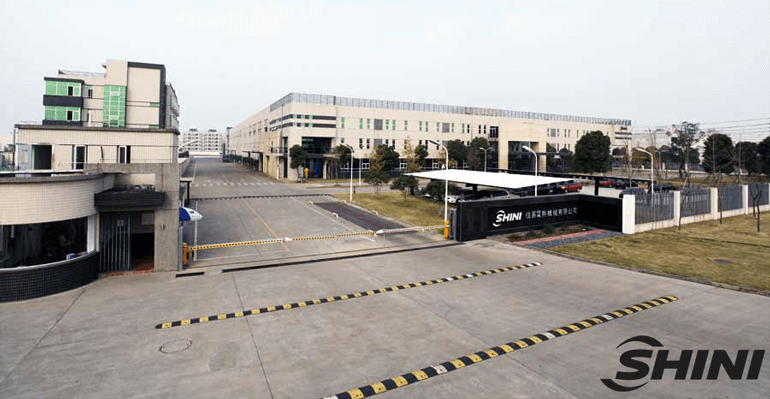

SHINI GROUP: The Application of Plastic Molding Auxiliary Equipment in Auto Parts Industry

Shini was founded in 1969, and it has been running for over 52 years since its establishment. Through continuous sustainable exploration and progress, Shini can now provide eight series of products to the market...

CHAO WEI: How to Select the Suitable Bag Making Machine for You?

As the manufacturer of various models of plastic bag making machines, Chao Wei Plastic Machinery Co., Ltd always receives inquiries from potential customers who ask for quotations. Most inquirers always wish to buy one machine that can produce all models of plastic bags, but in reality, there is no such machine that can do all of them.

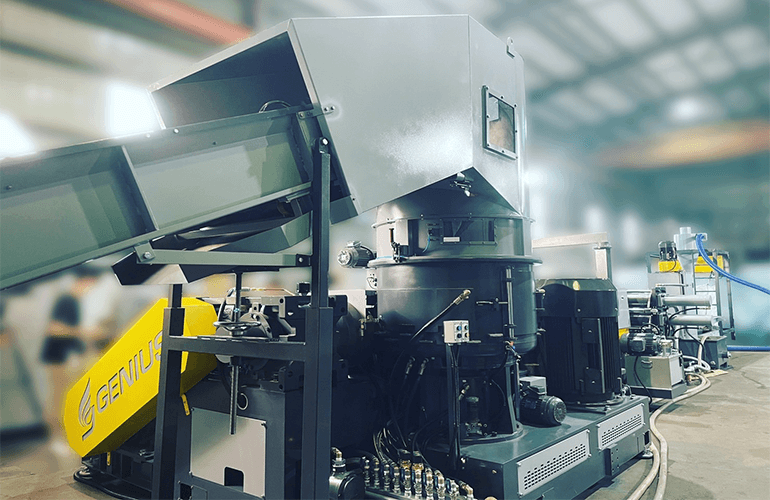

GENIUS: Constantly Adjusting to Different Recycling Policies Around the World

Genius Machinery has already served a lot of recyclers around the world, even in the pandemic period. They keep the principal motivation in their mind: increasing productivity creates more benefits and infinitive possibilities in the industrial area. Connect with Genius Machinery, to let them back you up. Smart Recycling, the Genius Way.

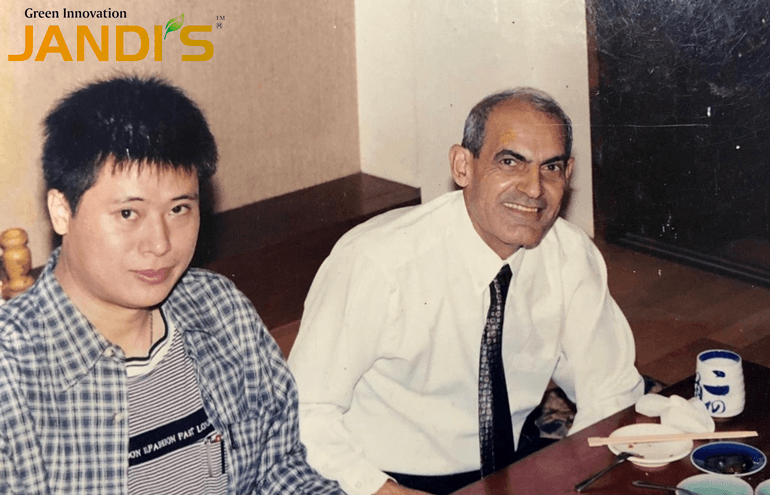

Mansef in Gaza – A Break Point of JANDI’S Vision

When JANDI’S newly established in the early 1990s, Jerry Huang, our general manager was in his early 30s, and his main responsibility was to raise the family, so he was focused on how to sell machines to make money. At that time, the middle east market, such as Saudi Arabia, Jordan, Lebanon, Syria, Egypt, UAE, Bahrain, Iran and Israel, is one of our main targets.

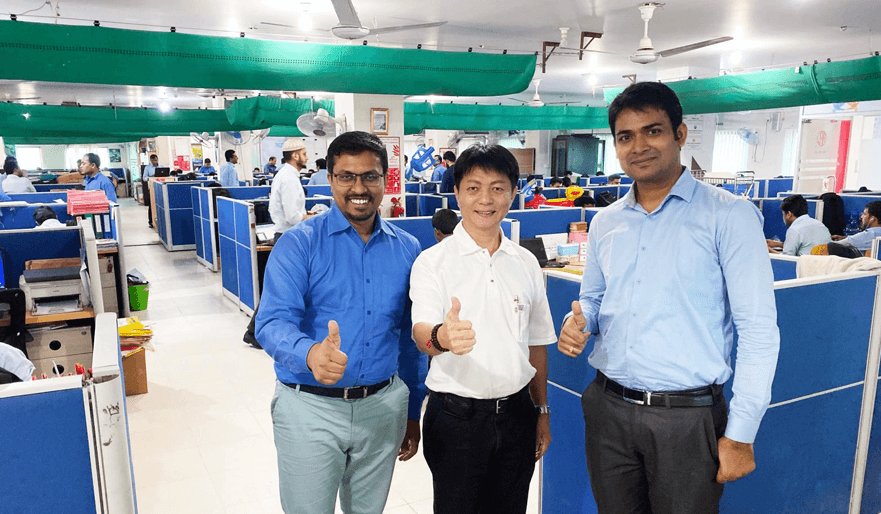

孟加拉塑膠市場需求強勁,FCS客戶穩坐家居用品龍頭品牌

隨著全球都市化/城市化的進步及經濟發展,家居用品作為民生消費品的一種,需求逐年增長,市場漸趨成熟、飽和。但在某些開發中國家,這些基本的民生用品才剛進入成長期。

POLYSTAR: Does your Factory have the Right Solution for Recycling your Materials?

Producers understand the relevance of recycling the plastic waste created by their facilities. The shortage of resins drove plastic producers to respond faster and take action to recycle their factory waste, and thus to explore innovative ways to recycle post-consumer waste.

TAIWAN KINKI: All Electric Vertical Injection Molding Machine for a More Eco-friendly Future

Reviewing the whole last year, the global economy was still deeply under COVID-19’s affections. Most countries were on lockdown for better control of the spread of COVID-19 hence caused a series of effects to all industries all over the world, especially international affairs which faced huge difficulties due to the limitations.

BoReTech: Innovation of PET Recycling with Latest EC Process Technology

In 2022, the subsidiary of BoReTech Group in Taiwan introduced the latest EC process technology of the PET bottle recycling system developed by BoReTech. The EC process has been completed development in 2021, it is the first time to be applied in the PET recycling project. The project adopts the hot washing and rinsing modular of the EC process PET bottle washing system.

JING DAY: Automation of Rubber Injection Moulding Machines

While crowds cheer and television audiences tune in to watch professional athletes test their skills against one another, few will give any immediate thought to something as seemingly banal as rubber — but rubbers play a significant role.

Your Innovative Extrusioneers from PLASCO

PLASCO is an Industry leader in design, manufacture, and supply of innovative plastic extrusion line to the market worldwide. Our performance spectrum range from individual extruder machine, to the engineering, planning, and delivery of complete turn-key factories. We offer our customer our speciality knowhow in the field of plastic extrusion, our innovations and engineering background is our core competence to provide customized solution and has driven us success for more than 30 years. Our advantages • With 2 manufacturing factories in Taiwan including test center. • More than 3600 PLASCO extrusion lines all over the world • Installed the extrusion lines in more than 80 countries worldwide • Focus on innovation and quality: independent R&D dep. and electrical engineer • Customized and top quality to satisfy customers • Convenient to find spare parts all over the world: we use the well-known global components for machines Work with PLASCO • Customized design & auxiliary equipment provided • Efficiency & exact lead-time • Service & support: installation, operation training, and technical knowledge support • CE certificate of compliance With its high level of reliability, efficiency, energy saving concept, and top quality finish product, PLASCO plastic extrusion line ensures the modest investment compared with its high productivities to facilitate the ever-demand requirement of all market sectors.

Join us and Share your Articles with our Audience!

Do you want to publish your articles in our platform for FREE? We would like to get an Industry Insight on your local market, please feel free to contact us to discuss more details.