近期更新 立即訂閱

The Multilayer Film Boom: Why Companies are Investing

International Plastics News for Asia | Chi-Chuan Cheng The Multi-Layer Co-Extrusion Film Blowing Machine plays a vital role in modern plastic production with its benefits of high efficiency, automation, precision, and energy efficiency. It finds applications not only in food, building materials, and agriculture but also in fields like medicine, chemical, and electronics.

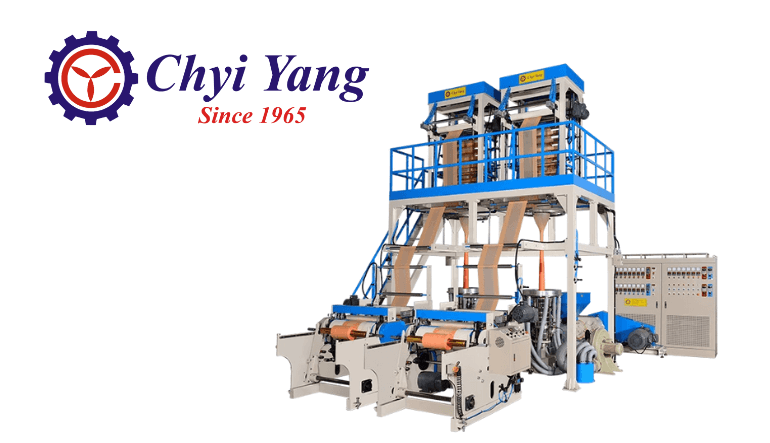

Quality Triumphs Cost ── Lessons from a Leading Vietnamese Industrial Player CHYI YANG's Customer-Centric Approach

International Plastics News for Asia | Chi-Chuan Cheng The crucial consideration for manufacturers is whether to cut costs or enhance value. There is a well-established plastic film producer located in Hanoi, Vietnam, which a few years ago purchased blown film machines from the renowned quality-driven company, Chyi Yang. However, due to price considerations, the factory later shifted to purchasing low-cost multilayer blown film machines manufactured in China, temporarily expanding its production capacity. Despite momentarily stepping back from the price competition, Chyi Yang remains steadfast in its commitment to quality-driven development, continuously innovating and advancing with the introduction of various styles of 5-layer / 7-layer co-extrusion blown film machines.

Path to a Greener Tomorrow── CHYI YANG's CFV Solutions of Precision and Sustainability

Global environmental awareness has prompted the manufacturing industry to transition towards green production. The need for "carbon reduction" in the CFV stages has led the global blown film manufacturing industry to pursue sustainable development solutions. Chyi Yang's 5-layer / 7-layer co-extrusion blown film machines have become a key player in today's green supply chain due to their three key advantages: "Big Data Analysis," "Precision Formulation and Calculation Functions," and "Recycled Waste Technology Innovations" in their multi-layer blown film machines. The international blown film manufacturing market also recognizes the indispensability of Chyi Yang in the trend of carbon reduction.

Innovations in Taiwanese Blown Film Industry: Explore the role of Kung Hsing as a pioneering force in the blown film industry

As an innovative leader in the Taiwanese blown film sector, Kung Hsing, with over 50 years of accumulated experience, collaborates with customers to drive innovation. Facing the diverse needs of customers and various issues in blown film, how does Kung Hsing continuously progress, and provide blown film equipment that is superior for film factories worldwide?

CHYI YANG: The Features of HDPE Bags & Film

High Density Polyethylene Resin, briefly, HDPE film grade resin mainly designed for producing shopping bags, T-shirt bags, grocery bags, garbage bags, food packaging and many so on.

CACO3 & Recycling Material Revolution in HDPE Bags

Nowadays, for HDPE shopping bags, T-shirt bags & food packaging bags, it’s very popular to blend recycled material & calcium carbonate (CACO3). Especially CACO3, it can cut down your resin cost, increase capacity & make your film products heavier. Although CACO3 provides so many advantages, it changes the feature of HDPE film. HDPE film will be reduced in tensile strength after blending CACO3, so that HDPE film won’t pack heavy subjects. Besides, CACO3 will make HDPE film feels dusty.

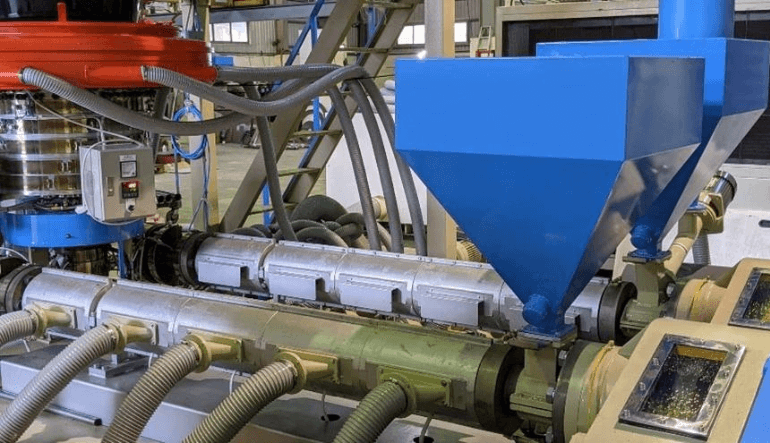

Guide to Blown Film Extrusion Machines

The process to produce the film is similar to blowing bubbles. The blown film machine virtually replicates the blowing process on its tower-like production line except it uses polymers (plastic materials) to replace soap water and nip the continuously blown bubble into an extremely thin film. The tower structure ranges several stages high. After the film is formed, it is wound into rolls and later distributed for final applications. As one of the leading blown film extrusion machine manufacturers with over 50-year-experience in Taiwan, now CHYI YANG is going to break down the process into details and discuss how blown film extrusion works.

5 Advantages of POLYSTAR for Your Plastic Recycling and Blown Film Businesses

As a leading manufacturer in the plastic industry, more than 4950 POLYSTAR plastic recycling machines and blown film extruders are operating in 110 countries today. This is a result of our satisfied customers, who have experienced the advantages of using POLYSTAR machines for their businesses. Here we have listed 5 of those advantages that are most pointed out based on our customers' feedback.

Sustainability Benefits for Plastic Film Producers

Why do producers want to recycle plastics? Although plastic is a very popular material, on a global level, less than 10% of it is recycled. With plastic waste being in such a high supply, producers could benefit from incorporating recycling into their existing business model. A recent study by business and daily found that 72% of the respondents are actively buying more environmentally friendly products than they did 5 years ago.

Crucial Factors for a Complete Circular Economy

The production of plastic bags and plastic films around the globe is huge. In recent years, producers have implemented new technologies to complete a circular economy in their factories. To make this possible, producers need a plastic recycling system that produces good quality pellets and a blown film machine that can process up to 100% recycled plastic pellets.

POLYSTAR: Film Extruder with Twin Head – Efficient For Bag Production?

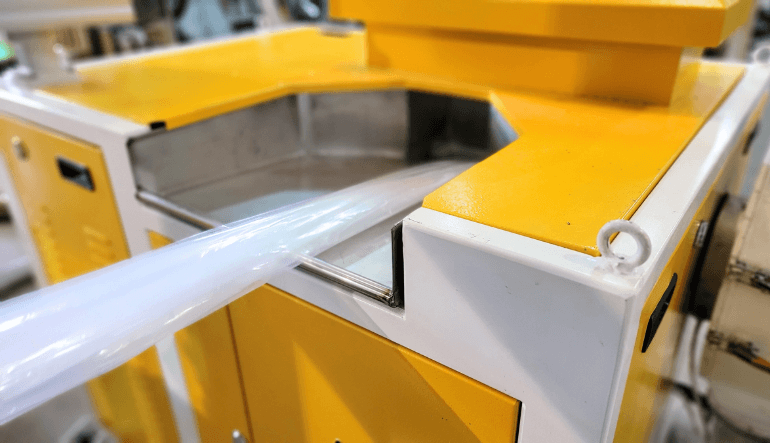

Compared to extruders with single die heads, the double-die extruders can achieve higher production capacity when producing film rolls that are small in width, as the high extrusion output is dispersed into two separate channels of the die heads instead of one.

POLYSTAR - How to Obtain Excellent Quality Plastic Films for Lamination?

Laminated film is an excellent application for packaging food like coffee, snacks, cookies, nuts (peanuts, pistachio, almonds), and others. It is ideal for packaging because laminated films have protection from humidity, oxygen, aromas, fats, and light. All these factors decompose or reduce the lifetime of the packaged product. For this reason, the protective barrier is the most important element in the laminated film, which is composed of PE (LDPE), BOPP, PET, and others.