PET吹瓶機系列-TEM04M1

產品分類 : 全自動中空成型機

特點採用64K彩色觸摸屏控制系統,PLC操作友好。獨特設計的機器結構使將吹塑機與輸送機系統結合起來非常方便。瓶胚自動排列,以便以單一方式供料,分料架由伺服電機驅動;這樣可以避免瓶坯卡住,機器掉落或瓶坯浪費。採用伺服控制螺桿驅動系統;它是快速,穩定,清潔和環保的。將預成型坯以矩陣模式送入加熱系統,並通過單燈和雙面加熱均勻加熱。採用帶有雙面加熱設計的單燈,與競爭對手的方法相比,將節省約50%的熱量消耗。具有溫度反饋功能,通過調節紅外燈自動控制加熱爐中的溫度,以減少預結晶的問題。特殊設計的加熱箱可提高更換紅外燈和冷卻坡道的維護便利性。夾緊機構由伺服電機和凸輪驅動。這樣可以實現準確而穩定的運動,低噪音和最小的污染。利用空氣回收系統,效率高達50%,因此不需要低壓空氣壓縮機。這將節省設備投資成本和能源消耗多達15%。

CONTRACT MOLD MANUFACTURE

產品分類 : 熱澆道系統

CONTRACT MOLD MANUFACTURE Yomura offers production molds that will be to customer’s facility or a manufacturing location designated. We manufacture molds for almost every major end market for plastics, like, housewares and delicate medical parts, aerospace parts, automotive parts or tiny parts for consumer electronics. All the molds are built to your specification, including type of steel, runner system, gate type, cavity materials and other features specified. Whenever the molds arrive at your facility, they can fit directly to your injection molding machines and are ready for production. ADVANTAGES Early involvement in design phase Ability to provide accurate and quick mold quote Low cost, quick build and high quality A price fully competitive with major mold makers around the global Long life-cycle and low maintenance Reliable delivery schedules Delivery of bug-free molds and ready for production as soon as arrival Complete integrated design and project management services Adapting the latest technology in design and advanced machine tools Ability to communicate quickly and efficiently, and easy to work with Close to superhighway, allowing for quick travel Service centers and international offices are available in major market countries Joint mold making operations with mold makers in other countries bring Yomura closer to the customers PROCESS FOR CONTRACT MOLD MANUFACTURE Customer supplies 3D CAD file to acquire quote Yomura starts the mold order process based on confirmation Yomura sends the 3D full mold design for your review and approval Yomura starts to build the injection mold upon approval Pilot and short production run after mold completion Sample approval Tooling delivery to location specified

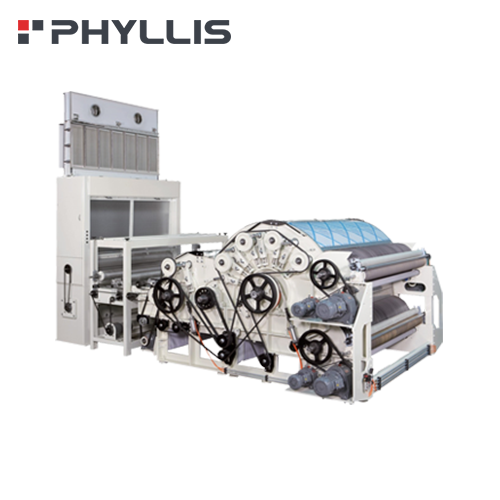

熱熔膠高速全自動圓瓶/方瓶貼標機MD-3000RS-OPP

產品分類 : 標籤機

1. 適用方瓶及圓瓶 2. 全自動旋轉式貼標機適用330ml-4000ml瓶子(更換零件) 3. 機台外罩304不鏽鋼 4. PLC控制系統及觸控螢幕,變頻控制 5. 採星狀盤分瓶入料,高速進瓶穩定不倒瓶 6. 標籤供應方式採用伺服馬達同步追蹤切斷,高速吸附貼標,精準穩定 7. AC三相變頻控制,搭配PLC及同步追蹤控制系統,不論高速或低速皆能保持標籤裁斷精度 8. 集中式潤滑系統,機械保養更簡單 9. 使用電眼檢測入料狀況,依生產線來料狀況自動調整貼標快慢,能完全達到生產線之連貫性 10. 系統安全裝置設計,當扭力異常或入料異常時,系統會立刻停機,確保設備使用壽命及操作安全 11. 自動標籤校對系統採用德國進口控制器 12. 同步追蹤系統採用德國進口控制器 13. 自動自我調節與其他機台連線之生產速度

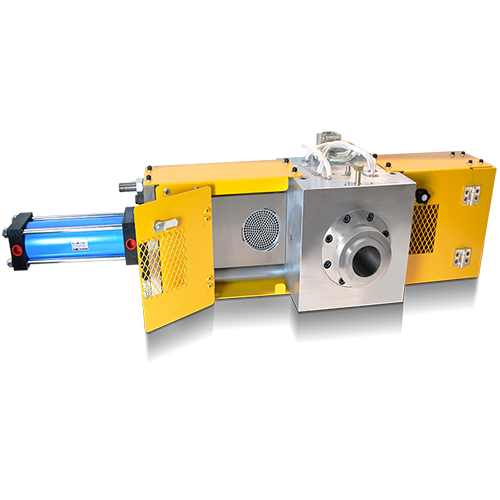

環保型雙機直結模頭切膠粒製造機(水冷式)

產品分類 : 製粒機

• 型號: TY-LBW 系列 • 產地: 台灣 • 適用樹脂: PP,PE,ABS,PS,HIPS. • 特殊使用樹脂: POM,PC,ACRYLIC • 產能: 100~800 kg/小時

尼龍 6 工程塑膠 - NA7200GK50

產品分類 : PA樹脂/尼龍

50%玻璃纖維增強 (黑色-高剛性、高耐衝擊) 應用說明:手工具、電動工具、園藝工具用,汽車、機車、腳踏車零組件用,運動器材零組件用,電子、電器外殼及零組件用,O.A.辦公室零組件用,水資材用,醫療復健器材。

奧地利KEBA控制器-I series control unit

產品分類 : 控制設備

EUROPEAN QUALITY ELEMENTS ENSURE PERFECT PERFORMANCE FOR IMM ● High-performance 32 bit processor ● All I/Os for standard injection molding machines ● PWM current outputs for direct control of proportional valves ● Optimized digital outputs for hydraulic switching valves ● Thermocouple inputs for different types of sensors ● Pulse input for screw speed ● Ethernet connection for host computer ● USB connection for printer, modem, USB stick, etc.

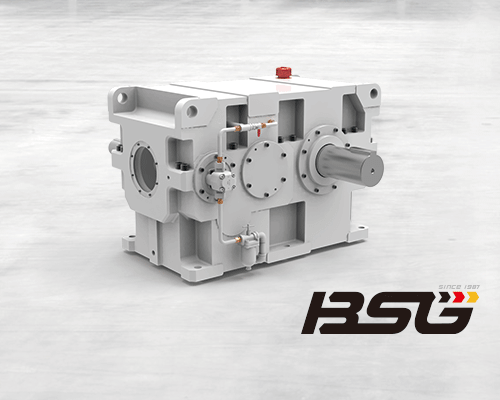

全電式射出成型機齒輪箱

產品分類 : 齒輪箱

三隆精心研製之射出成型機齒輪箱有效驅動射出機射膠螺桿。搭配平行入、出力軸之齒輪箱,依據客戶個別需求,設計適合傳動高扭矩力之齒輪箱,使齒輪箱具備極優異之低噪音、低振動特性。

PVC專用射出成型機-90PVC – 320PVC

產品分類 : 臥式射出成型機

Common commissioning for molding products such as fittings of a highly acid chemical. A one-piece rod and a standard L/D ratio screw design makes melt flow smoothly. Includes a standard, grade B, bimetallic screw barrel to provide a better wear-resistance and lifespan. Radiation fans set on top of the sleeve of the barrel to avoid overheating issues of the rigid PVC inside of the barrel.

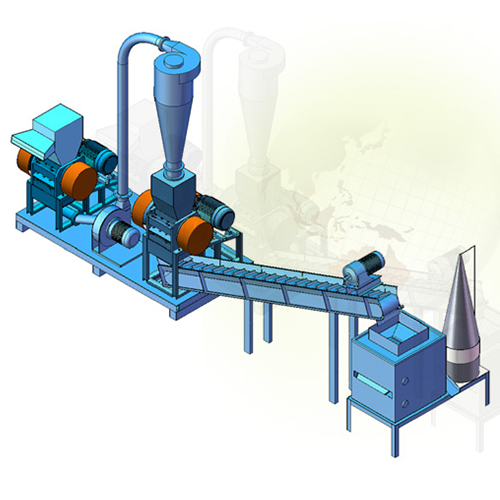

廢電纜線回收處理線

廢電纜線回收處理線 電線電纜粉碎分離回收設備是一種先進的技術。主要適用於不同的廢電線 /電纜,塑料包裝分離結節從銅線(銅顆粒)通過破碎,研磨,粉碎結節,而塑料是由振動系統的進一步分離,然後完全隔離空氣分離包裝從結節。設備的特點是自動化程度高,適應性好,生產效率高,純度銅結節

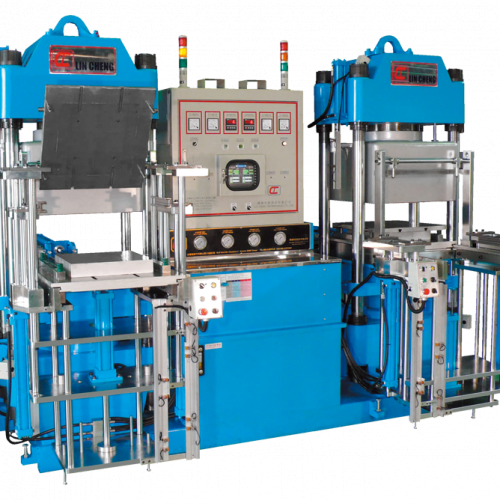

2RT開模輪胎膠囊專用橡膠後射式成型機

產品分類 : 橡膠射出成型機

2RT超越了傳統的頂部開模,可用於雙模或三模,並具有開模的設計並在兩者之間推出模具。可以通過軟件調整開模,並分別打開,分開推開模具,連續打開和連續推開模具。

3RT 開模橡矽膠真空熱壓成型機 VCC-D3

產品分類 : 雨靴注塑機

●3RT架構特點在於超越一般傳統的頂式掀模,可用於三層或四層模具之特殊功能,具有掀模及中層模具個別頂出之設計 ●此掀模功能具有分段掀模、分段中模頂出、連續掀模及中模頂出之軟體設計,可依操作需要做調整。

一段兩工位式射出延伸吹瓶機 - ISB 系列

產品分類 : 射出中空成型機

本機種採用最先進『 一步法射出延伸吹瓶 』成形工藝,祇需單機即可達到高質量產出效率,比較兩步法PET成型機,本機所佔優勢包括:節約能源--低耗電率、節省設備佔用空間、單機採購可減少開發試模風險、開模成本低--迎合市場產品多樣化需求、專適於小容量精緻容器,因此可提昇客戶接單之競爭力。

圓瓶貼標機 KWT-500-Serials

產品分類 : 標籤機

KWT-500系列貼標機,適用於圓瓶貼標。 * KWT-510 圓瓶自動貼標機/HUNTER KWT-510 智慧型圓瓶自動貼標機 : 設計適合在圓形容器的全繞貼或半繞貼。 * KWT-515 定點圓瓶自動貼標機 : 設計適合在同一個圓形容器貼一張或兩張標籤。

Proportional-Device

產品分類 : 篩選機

高精密偏光板切片機 TRC-1200

產品分類 : 切割機

Stable Bottomdead Center Accuracy: The delicate-design mechanism can maintain the stable bottomdead center accuracy under high speed cutting running. Knife Height Adjustment Mechanism: When setting up knife mold, the instrument of the machine can make right and left adjustment respectively as well as complete the setup of knife mold clearly and rapidly. Easy-Operate Operation Panel: This machine adopts new touch screen featuring affinity operation interface that makes an easy operation, thus lowering cost for employee training. Accuracy Delivery Mechanism: Oaded with new mechanism, the delivery move volume digital setup, it achieves a stable an accurate delivery function. High Speed Cutting: The strengthened-design mechanism can allow high speed cutting. High Torsiodamper: With the strong rigidity of the unit, noise can be maintained within the standard value under high speed running.

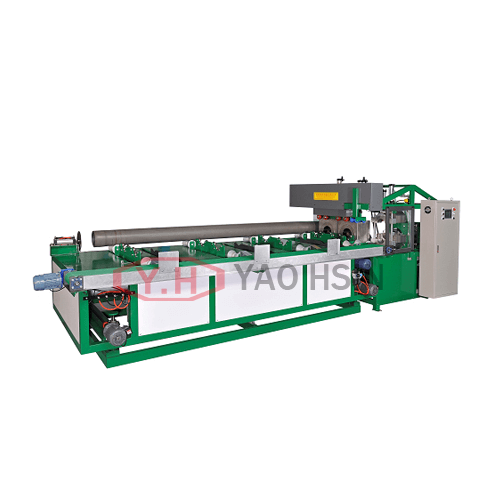

雙管平口式自動進料擴管機

產品分類 : 管材及異型材押出生產線

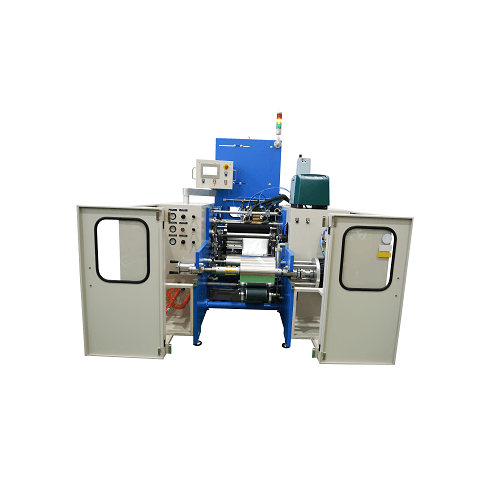

SIX SHAFTS TYPE AUTOMATIC ALUMINUM FOIL / CLING FILM REWINDER (AH-6S)

產品分類 : 分切機和複捲機

AH-6S, the six shaft type automatic rewinding machine. It's designed for rewind aluminum, PE and PVC cling film. The feeding press roller is carried with precise pressure manometer and regulating valve. Movements include automatic feeding material, automatic cutting and unloading the finished product. This model has automatic length correcting function. It can correct the margin of product length anytime. There are 2 type of mother roll width for AH-6S: from 250-450 mm, and from 300-500 mm. The product length is from 3-250 meters, the finished paper core's I.D. can be appointed within 25-38 mm. Users can choose to equip label sticker device and hot melt glue device with machine. They will make product more perfect. Stably fix the material on the paper core, neatly produce product with smooth edge. Machine brings you a huge benefit in the way you need. Welcome to consult machine with us. We will at your service.

EPE 發泡管、套角押出機系列

產品分類 : 發泡機